How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

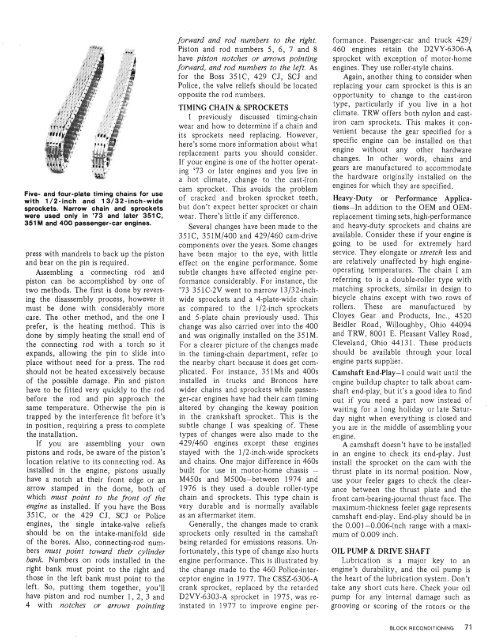

Five- and four-plate timing chains for use<br />

with 1 /2-inch and 13/32-inch-wide<br />

sprockets. Narrow chain and sprockets<br />

were used only in '73 and later <strong>351C</strong>,<br />

351 M and <strong>400</strong> passenger-car engines.<br />

press with mandrels to back up the piston<br />

and bear on the pin is required.<br />

Assembling a connecting rod and<br />

piston can be accomplished by one <strong>of</strong><br />

two methods. The first is done by reversing<br />

the disassembly process, however it<br />

must be done with considerably more<br />

care. The other method, and the one I<br />

prefer, is the heating method. This is<br />

done by simply heating the small end <strong>of</strong><br />

the connecting rod with a torch so it<br />

expands, allowing the pin to slide into<br />

place without need for a press. The rod<br />

should not be heated excessively because<br />

<strong>of</strong> the possible damage. Pin and piston<br />

have to be fitted very quickly to the rod<br />

before the rod and pin approach the<br />

same temperature. Otherwise the pin is<br />

trapped by the interference fit before it's<br />

in position, requiring a press to complete<br />

the installation.<br />

If you are assembling your own<br />

pistons and rods, be aware <strong>of</strong> the piston's<br />

location relative to its connecting rod. As<br />

installed in the engine, pistons usually<br />

have a notch at their front edge or an<br />

arrow stamped in the dome, both <strong>of</strong><br />

which must point to the front <strong>of</strong> the<br />

engine as installed. If you have the Boss<br />

<strong>351C</strong>, or the <strong>429</strong> CJ, SCJ or Police<br />

engines, the single intake-valve reliefs<br />

should be on the intake-manifold side<br />

<strong>of</strong> the bores. Also, connecting-rod numbers<br />

must point toward their cylinder<br />

bank. Numbers on rods installed in the<br />

right bank must point to the right and<br />

those in the left bank must point to the<br />

left. So, putting them together, you'll<br />

have piston and rod number 1, 2, 3 and<br />

4 with notches or arrows pointing<br />

forward and rod numbers to the right.<br />

Piston and rod numbers 5, 6, 7 and 8<br />

have piston notches or arrows pointing<br />

forward, and rod numbers to the left. As<br />

for the Boss <strong>351C</strong>, <strong>429</strong> CJ, SCJ and<br />

Police, the valve reliefs should be located<br />

opposite the rod numbers.<br />

TIMING CHAIN & SPROCKETS<br />

I previously discussed timing-chain<br />

wear and how to determine if a chain and<br />

its sprockets need replacing. <strong>How</strong>ever,<br />

here's some more information about what<br />

replacement parts you should consider.<br />

If your engine is one <strong>of</strong> the hotter operating<br />

'73 or later engines and you live in<br />

a hot climate, change to the cast-iron<br />

cam sprocket. This avoids the problem<br />

<strong>of</strong> cracked and broken sprocket teeth,<br />

but don't expect better sprocket or chain<br />

wear. There's little if any difference.<br />

Several changes have been made to the<br />

35 lC, <strong>351M</strong>1<strong>400</strong> and <strong>429</strong>1460 cam-drive<br />

components over the years. Some changes<br />

have been major to the eye, with little<br />

effect on the engine performance. Some<br />

subtle changes have affected engine performance<br />

considerably. For instance, the<br />

'73 <strong>351C</strong>-2V went to narrow 13132-inchwide<br />

sprockets and a 4-plate-wide chain<br />

as compared to the 112-inch sprockets<br />

and 5-plate chain previously used. This<br />

change was also carried over into the <strong>400</strong><br />

and was originally installed on the <strong>351M</strong>.<br />

For a clearer picture <strong>of</strong> the changes made<br />

in the timing-chain department, refer fo<br />

the nearby chart because it does get complicated.<br />

For instance, <strong>351M</strong>s and <strong>400</strong>s<br />

installed in trucks and Broncos have<br />

wider chains and sprockets while passenger-car<br />

engines have had their cam timing<br />

altered by changing the keway position<br />

in the crankshaft sprocket. This is the<br />

subtle change I was speaking <strong>of</strong>. These<br />

types <strong>of</strong> changes were also made to the<br />

<strong>429</strong>1460 engines except these engines<br />

stayed with the 112-inch-wide sprockets<br />

and chains. One major difference in 460s<br />

built for use in motor-home chassis -<br />

M450s and MSOOs-between 1974 and<br />

1976 is they used a double roller-type<br />

chain and sprockets. This type chain is<br />

very durable and is normally available<br />

as an aftermarket item.<br />

Generally, the changes made to crank<br />

sprockets only resulted in the camshaft<br />

being retarded for emissions reasons. Unfortunately,<br />

this type <strong>of</strong> change also hurts<br />

engine performance. This is illustrated by<br />

the change made to the 460 Police-interceptor<br />

engine in 1977. The C8SZ-6306-A<br />

crank sprocket, replaced by the retarded<br />

D2VY-6303-A sprocket in 1975, was reinstated<br />

in 1977 to improve engne per-<br />

formance. Passenger-car and truck <strong>429</strong>1<br />

460 engines retain the D2VY-6306-A<br />

sprocket with exception <strong>of</strong> motor-home<br />

engines. They use roller-style chains.<br />

Again, another thing to consider when<br />

replacing your cam sprocket is this is an<br />

opportunity to change to the cast-iron<br />

type, particularly if you live in a hot<br />

climate. TRW <strong>of</strong>fers both nylon and castiron<br />

cam sprockets. This makes it convenient<br />

because the gear specified for a<br />

specific engine can be installed on that<br />

engine without any other hardware<br />

changes. In other words, chains and<br />

gears are manufactured to accommodate<br />

the hardware originally installed on the<br />

engines for which they are specified.<br />

Heavy-Duty or Performance Applications-In<br />

addition to the OEM and OEMreplacement<br />

timing sets, high-performance<br />

and heavy-duty sprockets and chains are<br />

available. Consider these if your engine 1s<br />

going to be used for extremely hard<br />

service. They elongate or stretch less and<br />

are relatively unaffected by high engineoperating<br />

temperatures. The chain I am<br />

referring to is a double-roller type with<br />

matching sprockets, similar in design to<br />

bicycle chains except with two rows <strong>of</strong><br />

rollers. These are manufactured by<br />

Cloyes Gear and Products, Inc., 4520<br />

Beidler Road, Willoughby, Ohio 44094<br />

and TRW, 8001 E. Pleasant Valley Road,<br />

Cleveland, Ohio 44131. These products<br />

should be available through your local<br />

engine parts supplier.<br />

Camshaft End-Play-I could wait until the<br />

engine buildup chapter to talk about camshaft<br />

end-play, but it's a good idea to find<br />

out if you need a part now instead <strong>of</strong><br />

waiting for a long holiday or late Saturday<br />

night when everything is closed and<br />

you are in the middle <strong>of</strong> assembling your<br />

engine.<br />

A camshaft doesn't have to be installed<br />

in an engine to check its end-play. Just<br />

install the sprocket on the cam with the<br />

thrust plate in its normal position. Now,<br />

use your feeler gages to check the clearance<br />

between the thrust plate and the<br />

front cam-bearing-journal thrust face. The<br />

maximum-thickness feeler gage represents<br />

camshaft end-play. End-play should be in<br />

the 0.001-0.006-inch range with a maximum<br />

<strong>of</strong> 0.009 inch.<br />

OIL PUMP & DRIVE SHAFT<br />

Lubrication is a major key to an<br />

engine's durability, and the oil pump is<br />

the heart <strong>of</strong> the lubrication system. Don't<br />

take any short cuts here. Check your oil<br />

pump for any internal damage such as<br />

grooving or scoring <strong>of</strong> the rotors or the