How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

This is the part <strong>of</strong> engine building I<br />

like. Everything is clean, all the parts are<br />

new, reconditioned or have been checked<br />

out. The running around associated with<br />

getting parts and jobs done you couldn't<br />

handle is just about over.<br />

Things You Need Before Starting-Just<br />

like all the jobs you've done until now,<br />

there are things you'll need for assembling<br />

your engine in addition to all the parts.<br />

Trash bags are useful for covering up<br />

clean parts, particularly the block, during<br />

assembly. You'll aso need a complete<br />

gasket set, gasket sealer, gasket or weatherstrip<br />

adhesive and a spray can <strong>of</strong> aluminum<br />

paint. All sorts <strong>of</strong> sealers and adhesives<br />

are available, but I'll list a few that<br />

work particularly well in certain applications.<br />

First is room-temperature-vulcanizing<br />

(RTV) silicone sealer. It's great if<br />

it's used right in the right place and in the<br />

right amount. Used incorrectly, it can be<br />

disastrous. You have to know its limitations.<br />

It's not a cure-all. <strong>Ford</strong> markets<br />

some fine sealers. Perfect Sealing Conlpound,<br />

B5A-195 54-A, is a general-purpose<br />

sealer. Gasket and Seal Contact Adhesive,<br />

D7AZ-19B508-A is especially good for installing<br />

intake-manifold gaskets. Another<br />

good one for this purpose is OMC's (Outboard<br />

Marine Corporation) Adhesive<br />

Type M. You can also use weatherstrip<br />

adhesive as a gasket-adhesive: <strong>Ford</strong>'s<br />

COAZ-19552-A or 3M Corporation's<br />

08001.<br />

Lubricants are a necessity when assembling<br />

an engine. <strong>How</strong> an engine's critical<br />

parts are lubricated during its first<br />

few minutes <strong>of</strong> initial run-in will be a<br />

major determining factor in the engine's<br />

durability. Remember this during the<br />

assembly process. Lubricants to have on<br />

hand include at least a quart <strong>of</strong> the oil<br />

you intend to use in your engine's crankcase-probably<br />

a multi-grade detergent<br />

type-a can <strong>of</strong> oil additive and some<br />

moly bdenum-disulfide grease. As for<br />

what brand <strong>of</strong> oil to use, I won't make<br />

any suggestions because the brand isn't as<br />

important as the grade. So, regardless <strong>of</strong><br />

the brand you choose, use the SE grade.<br />

In addition to crankcase oil, get a couple<br />

<strong>of</strong> cans <strong>of</strong> <strong>Ford</strong>'s Oil Conditioner, D2AZ-<br />

19579-A, or GM's EOS (Engine Oil Supplement)<br />

for general engine assembly,<br />

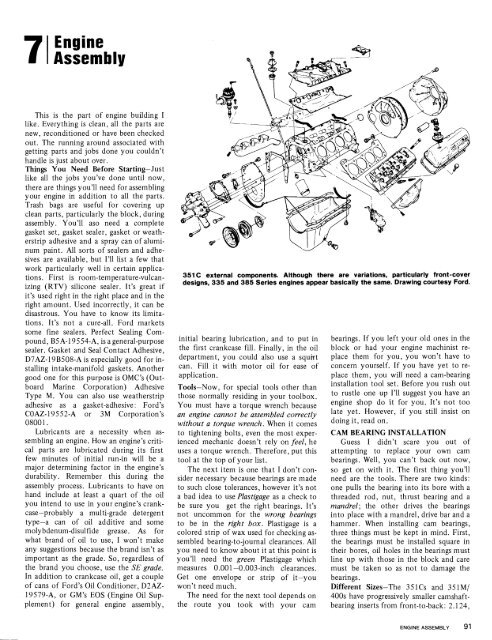

<strong>351C</strong> external components. Although there are variations, particularly front-cover<br />

designs, 335 and 385 Series engines appear basically the same. Drawing courtesy <strong>Ford</strong>.<br />

initial bearing lubrication, and to put in<br />

the first crankcase fill. Finally, in the oil<br />

department, you could also use a squirt<br />

can. Fill it with motor oil for ease <strong>of</strong><br />

application.<br />

<strong>To</strong>ols-Now, for special tools other than<br />

those normally residing in your toolbox.<br />

You must have a torque wrench because<br />

an engine cannot be assembled correctly<br />

without a torque wrench. When it comes<br />

to tightening bolts, even the most experienced<br />

mechanic doesn't rely on feel, he<br />

uses a torque wrench. Therefore, put this<br />

tool at the top <strong>of</strong> your list.<br />

The next item is one that I don't consider<br />

necessary because bearings are made<br />

to such close tolerances, however it's not<br />

a bad idea to use Plastigage as a check to<br />

be sure you get the right bearings. It's<br />

not uncommon for the wrong bearings<br />

to be in the right box. Plastigage is a<br />

colored strip <strong>of</strong> wax used for checking assembled<br />

bearing-to-journal clearances. All<br />

you need to know about it at this point is<br />

you'll need the green Plastigage which<br />

measures 0.001 -0.003-inch clearances.<br />

Get one envelope or strip <strong>of</strong> it-you<br />

won't need much.<br />

The need for the next tool depends on<br />

the route you took with your cam<br />

bearings. If you left your old ones in the<br />

block or had your engine machinist replace<br />

them for you, you won't have to<br />

concern yourself. If you have yet to replace<br />

them, you will need a cam-bearing<br />

installation tool set. Before you rush out<br />

to rustle one up I'll suggest you have an<br />

engine shop do it for you. It's not too<br />

late yet. <strong>How</strong>ever, if you still insist on<br />

doing it, read on.<br />

CAM BEARING INSTALLATION<br />

Guess I didn't scare you out <strong>of</strong><br />

attempting to replace your own cam<br />

beariigs. well, you can't back out now,<br />

so get on with it. The first thing you'll<br />

need are the tools. There are two kinds:<br />

one pulls the bearing into its bore with a<br />

threaded rod, nut, thrust bearing and a<br />

mandrel; the other drives the bearings<br />

into place with a mandrel, drive bar and a<br />

hammer. When installing cam bearings,<br />

three things must be kept in mind. First,<br />

the bearings must be installed square in<br />

their bores, oil holes in the bearings must<br />

line up with those in the block and care<br />

must be taken so as not to damage the<br />

bearings.<br />

Different Sizes-The 351 Cs and <strong>351M</strong>/<br />

<strong>400</strong>s have progressively smaller camshaftbearing<br />

inserts from front-to-back: 2.124,