How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

tively. Because the bearing shells are the<br />

same thickness, the <strong>351C</strong> and <strong>351M</strong>1<strong>400</strong><br />

bearings must be installed in the right<br />

bearings bores. If you attempt to install<br />

one in the wrong bore, it will fit loosely,<br />

or be destroyed. The <strong>429</strong>1460 bearing<br />

journals all have a 2.1 24-inch diameter.<br />

Chamfering the Bearings-Before installing<br />

your cam bearings, it's a good idea to remove<br />

the sharp edges from the inside<br />

edges <strong>of</strong> new bearings. They can interfere<br />

with the cam journals as you're trying to<br />

slide the cam into place, making cam installation<br />

more difficult than it needs to<br />

be. The tool particularly suited for this<br />

job is a bearingscraper. It's like a triangular<br />

file with no teeth. If You don't I.Iave One<br />

<strong>of</strong> these, use a pen knife.<br />

<strong>To</strong> chamfer the bearing ID, hold your<br />

knife or scraper 45" to the bearing surface<br />

and hold the bearing so you can rotate<br />

it while peeling a small shaving about<br />

the size <strong>of</strong> four human hairs-if you can<br />

picture the size <strong>of</strong> four hairs. The idea<br />

here is to remove just enough so you<br />

can't feel a burr when you drag your fingernail<br />

across the edges <strong>of</strong> the bearings.<br />

Get the Block and Bearings Ready-Put<br />

your cylinder block on its back so you'll<br />

have access for installing the bearing inserts.<br />

Also, it's best to locate the block SO<br />

you can easily sight down the center <strong>of</strong><br />

the bearing bores during the installation,<br />

particularly if you have a bearing installer<br />

that's not self-centering.<br />

After your block is positioned, organize<br />

the bearings in the same sequence they<br />

*-a,'<br />

. ,. -<br />

's'<br />

~k<br />

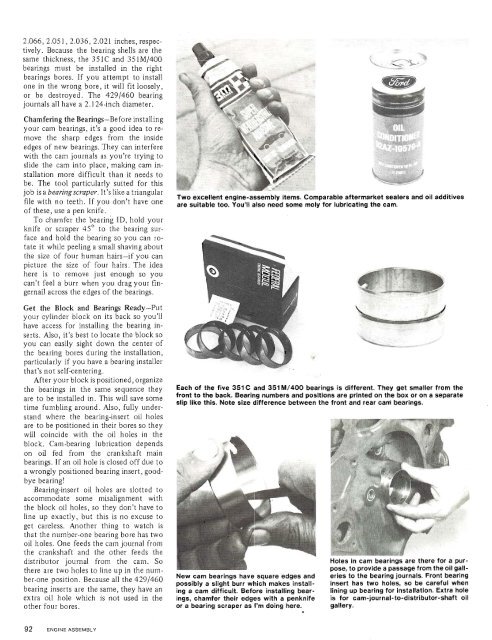

parable aftermarket sealers and oil additives<br />

for lubricating the cam.<br />

Each <strong>of</strong> the five 351 C and 351 M/<strong>400</strong> bearings is different. They get smaller from the<br />

front to the back. Bearing numbers and posltlons are printed on the box or on a separate<br />

are be in. This save slip like this. Note size difference between the front and rear carii bearings.<br />

time fumbling around. Also, fully understand<br />

where the bearing-insert oil holes<br />

are to be positioned in their bores so they<br />

will coincide with the oil holes in the<br />

block. Cam-bearing lubrication depends<br />

on oil fed from the crankshaft main<br />

bearings. If an oil hole is closed <strong>of</strong>f due to<br />

a wrongly positioned bearing insert, goodbye<br />

bearing!<br />

Bearing-insert oil holes are slotted to<br />

accommodate some misalignment with<br />

the block oil holes, so they don't have to<br />

line up exactly, but this is no excuse to<br />

get careless. Another thing to watch is<br />

that the number-one bearing bore has two<br />

oil holes. One feeds the cam journal from<br />

the crankshaft and the other feeds the<br />

distributor journal from the cam. So<br />

Holes in cam bearings are there for a purthere<br />

are two holes to line up in the num-<br />

pose, to provide a passage from the oil gall-<br />

New cam bearings have square edges and eries to the bearing journals. Front bearing<br />

position' Because the <strong>429</strong>1460 possibly a slight burr which makes install- insert has two holes, so be careful when<br />

bearing inserts are the same, they have an ing a cam difficult. Before installing bear- lining up bearing for installation. Extra hole<br />

extra oil hole which is not used in the ings, chamfer their edges with a penknife is for cam-journal-to-distributor-shaft oil<br />

other four bores. or a bearing scraper as I'm doing here. gallery.