How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

spots, the rod/s need to be checked with<br />

a dial-indicator that's part <strong>of</strong> an engine<br />

builder's connecting-rod conditioning<br />

hone. A telescoping gage and micrometer<br />

can also be used for checking. Recondition<br />

the rod/s as necessary.<br />

When a connecting rod is reconditioned,<br />

some material is precision ground<br />

from the bearing-cap mating surfaces.<br />

Next, the cap is reinstalled on the rod,<br />

bolts are torqued to spec and the bore is<br />

honed to the specified diameter. Honing<br />

corrects the bearing-bore diameter and<br />

concentricity and also restores the tooth,<br />

or surface <strong>of</strong> the bore which grabs the<br />

bearing insert to prevent it from spinning.<br />

Rod Bolts-Make sure you inspect the rod<br />

bolts very closely before attempting any<br />

other reconditioning <strong>of</strong> the rods. Don't<br />

hesitate to use a magnifying glass as you<br />

give them the old "eagle-eye." Replace<br />

any cracked bolts-a cracked rod bolt<br />

will eventually break and may totally<br />

destroy any engine.<br />

You have to remove the bolts to check<br />

them. <strong>To</strong> remove a rod bolt, clamp the<br />

big end <strong>of</strong> the rod in a vise between two<br />

blbcks <strong>of</strong> wood and drive the bolt straight<br />

out. Use something such as a brass punch<br />

to do this to prevent damaging the bolt.<br />

The original or new bolt can be installed<br />

by tightening it after it is loosely installed<br />

in the rod with the cap. If you replace<br />

one or both rod bolts, the connecting rod<br />

must be reconditioned or honed because<br />

the bolts locate the cap in relation to the<br />

rod. Consequently, changing a bolt may<br />

shift the cap in relation to the connecting<br />

rod.<br />

One last note concerning connecting<br />

rods. Rod-bearing bores are originally<br />

machined with their caps torqued in<br />

place, so they must be checked the same<br />

way.-When you deliver them to a machine<br />

shop for checking and reconditioning<br />

after you've inspected the rod bolts,<br />

make sure the correct cap is installed in<br />

each rod. <strong>To</strong>rque the nutsto specification<br />

before making the delivery; 40-45 ft. Ibs.;<br />

45-50 ft. Ibs. for <strong>351C</strong> Boss and HO.<br />

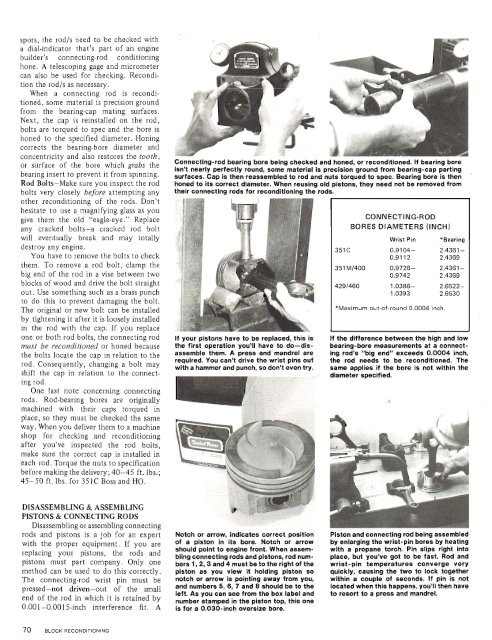

Connecting-rod bearing bore being checked and honed, or reconditioned. Ii - re<br />

isn't nearly perfectly round, some material is precision ground from bearing-cap parting<br />

surfaces. Cap is then reassembled to rod and nuts torqued to spec. Bearing bore is then<br />

honed to its correct dlameter. When reusing old pistons, they need not be removed from<br />

their connectlng rods for reconditlonlng the rods.<br />

CONNECTING-ROD<br />

BORES DIAMETERS (INCH)<br />

Wrist Pin<br />

*Bearing<br />

<strong>351C</strong> 0.9104-<br />

0.9112 2.4361 -<br />

2.4369<br />

351 MI<strong>400</strong> 0.9726-<br />

0.9742<br />

2.4361-<br />

2.4369<br />

<strong>429</strong>1460 1.0386-<br />

1.0393<br />

2.6522-<br />

2.6530<br />

*Maximum out-<strong>of</strong>-round 0.0004 inch.<br />

If your pistons have to be replaced, this is If the difference between the high and low<br />

the first operation you'll have to do-dis- bearing-bore measurements at a connectassemble<br />

them. A press and mandrel are ing rod's "blg end" exceeds 0.0004 inch,<br />

required. You can't drive the wrlst pins ouf the rod needs to be reconditioned. The<br />

with a hammer and punch, so don't even try. same applies if the bore is not within the<br />

-..._,.. - diameter specified.<br />

DISASSEMBLING & ASSEMBLING<br />

PISTONS & CONNECTING RODS<br />

Disassembling or assembling connecting<br />

rods and pistons is a job for an expert<br />

with the proper equipment. If you are<br />

replacing your pistons, the rods and<br />

pistons must part company. Only one<br />

method can be used to do this correctly.<br />

The connecting-rod wrist pin must be<br />

pressed-not driven-out <strong>of</strong> the small<br />

end <strong>of</strong> the rod in which it is retained by<br />

0.001 -0.001 5-inch interference fit. A<br />

Notch or arrow, indicates correct position<br />

<strong>of</strong> a piston in its bore. Notch or arrow<br />

should point to engine front. When assembling<br />

connecting rods and pistons, rod numbers<br />

l,2,3 and 4 must be to the right <strong>of</strong> the<br />

piston as you view It holding piston so<br />

notch or arrow is pointing away from you,<br />

and numbers 5,6, 7 and 8 should be to the<br />

left. As you can see from the box label and<br />

number stamped in the piston top, this one<br />

is for a 0.030-inch oversize bore.<br />

Piston and connecting rod being assembled<br />

by enlarging the wrist-pin bores by heating<br />

with a propane torch. Pln slips right into<br />

place, but you've got to be fast. Rod and<br />

wrist-pln temperatures converge very<br />

quickly, causing the two to lock together<br />

within a couple <strong>of</strong> seconds. If pin is not<br />

located when this happens, you'll then have<br />

to resort to a press and mandrel.