How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

When measuring piston diameter, do it level Scuff marks on piston skirt reveal engine<br />

Wear pattern on a piston skirt indicates<br />

connecting-rod alignment. If the pattern is<br />

symmetrical about the centerline <strong>of</strong> the<br />

skirt, rod alignment can be considered OK.<br />

ow ever, a skewed pattern like this shows<br />

with the wrist-pin and 90" to pin axis. Width was severely overheated. Further use will the rod is bent or twisted and should be<br />

measured across skirt bottom should be overstress and possibly collapse skirt. straightened. A checking fixture is required<br />

slightly larger-about 0.0005 inch. Scrap any piston that looks like this. for this.<br />

I<br />

I<br />

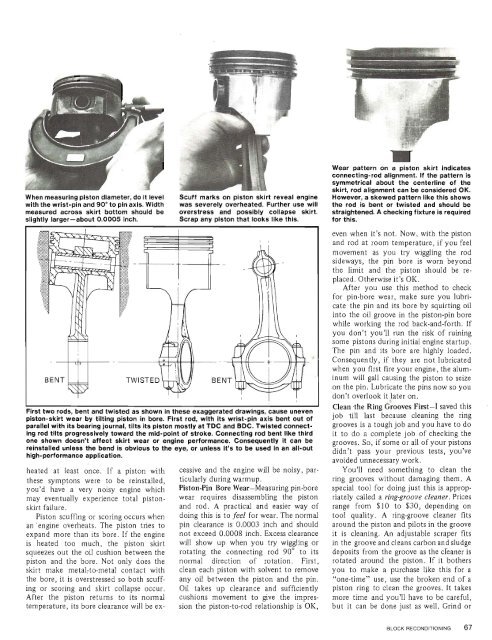

First two rods, bent and twisted as shown in these exaggerated drawlngs, cause uneven<br />

piston-skirt wear by tilting piston in bore. First rod, with its wrist-pin axis bent out <strong>of</strong><br />

parallel with its bearing journal, tilts its piston mostly at T DC and BDC. Twisted connecting<br />

rod tilts progressively toward the mid-point <strong>of</strong> stroke. Connecting rod bent like third<br />

one shown doesn't affect skirt wear or engine performance. Consequently it can be<br />

reinstalled unless the bend is obvious to the eye, or unless it's to be used In an all-out<br />

high-performance application.<br />

heated at least once. If a piston with<br />

these symptons were to be reinstalled,<br />

you'd have a very noisy engine which<br />

may eventually experience total pistonskirt<br />

failure.<br />

Piston scuffing or scoring occurs when<br />

an 'engne overheats. The piston tries to<br />

expand more than its bore. If the engine<br />

is heated too much, the piston skirt<br />

squeezes out the oil cushion between the<br />

piston and the bore. Not only does the<br />

skirt make metalrto-metal contact with<br />

the bore, it is overstressed so both scuffing<br />

or scoring and skirt collapse occur.<br />

After the piston returns to its normal<br />

temperature, its bore clearance will be ex-<br />

cessive and the engine will be noisy, particularly<br />

during warmup.<br />

Piston-Pin Bore Wear-Measuring pin-bore<br />

wear requires disassembling the piston<br />

and rod. A practical and easier way <strong>of</strong><br />

doing this is to feel for wear. The normal<br />

pin clearance is 0.0003 inch and should<br />

not exceed 0.0008 inch. Excess clearance<br />

will show up when you try wiggling or<br />

rotating the connecting rod 90' to its<br />

normal direction <strong>of</strong> rotation. First,<br />

clean each piston with solvent to remove<br />

any oil between the piston and the pin.<br />

Oil takes up clearance and sufficiently<br />

cushions movement to give the impression<br />

the piston-to-rod relationship is OK,<br />

even when it's not. Now, with the piston<br />

and rod at room temperature, if you feel<br />

movement as you try wiggling the rod<br />

sideways, the pin bore is worn beyond<br />

the limit and the piston should be replaced.<br />

Otherwise it's OK.<br />

After you use this method to check<br />

for pin-bore wear, make sure you lubricate<br />

the pin and its bore by squirting oil<br />

into the oil groove in the piston-pin bore<br />

while working the rod back-and-forth. If<br />

you don't you'll run the risk <strong>of</strong> ruining<br />

some pistons during initial engine startup.<br />

The pin and its bore are highly loaded.<br />

Consequently, if they are not lubricated<br />

when you first fire your engine, the aluminum<br />

will gall causing the piston to seize<br />

.on the pin. Lubricate the pins now so you<br />

don't overlook itJater on.<br />

Clean the Ring G~OOV~S First-l saved this<br />

job till last because cleaning the ring<br />

grooves is a tough job and you have to do<br />

it to do a complete job <strong>of</strong> checking the<br />

grooves. So, if some or all <strong>of</strong> your pistons<br />

didn't pass your previous tests, you've<br />

avoided unnecessary work.<br />

You'll need something to clean the<br />

ring grooves without damaging them. A<br />

special tool for doing just this is appropriately<br />

called a ring-groove cleaner. Prices<br />

range from $10 to $30, depending on<br />

tool quality. A ring-groove cleaner fits<br />

around the piston and pilots in the groove<br />

it is cleaning. An adjustable scraper fits<br />

in the groove and cleans carbon and sludge<br />

deposits from the groove as the cl'eaner is<br />

rotated around the piston. If it bothers<br />

you to make a purchase like this for a<br />

"one-time" use, use the broken end <strong>of</strong> a<br />

piston ring to clean the grooves. It takes<br />

more time and you'll have to be careful,<br />

but it can be done just as well. Grind or