How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

from losing it, put it back on the pushrod<br />

along with the clip. There may also be a<br />

wave washer. Put it back too.<br />

The equalizer bar fits between the<br />

engine and the frame or body. It pivots<br />

on a bracket attached to the frame or<br />

body with 2 bolts. After removing these<br />

bolts and the bracket, the equalizer bar<br />

will be free to pull <strong>of</strong>f its pivot at the engine,<br />

but you'll have to finish this job<br />

from underneath. This can usually be<br />

accomplished without raising your car by<br />

simply reaching the bellcrank-to-release<br />

lever under the car. Unhook it and the<br />

release-lever pushrod will swing free. You<br />

can now remove the bellcrank and pushrod<br />

together by sliding the bellcrank <strong>of</strong>f<br />

its engine pivot.<br />

Disconnect the Fuel Pump-Before breaking<br />

any fuel-line connections, make sure<br />

there are no open flames close by such as<br />

a gas water-heater pilot light. Disconnect<br />

the fuel-tank-to-fuel-pump line at the fuel<br />

pump. <strong>To</strong> prevent siphoning and the consequent<br />

fire hazard created by spilled gasoline,<br />

push a 318-in. diameter bolt into<br />

the end <strong>of</strong> the hose. Make sure the bolt<br />

isn't fully threaded. Otherwise fuel will<br />

leak out around the threads. It should<br />

have at least 112 in. <strong>of</strong> unthreaded shank.<br />

Get What You Can From the <strong>To</strong>p-If the<br />

exhaust-manifold-to-exhaust-pipe bolts<br />

are accessible from above, particularly the<br />

top ones, get them now. They are definitely<br />

easier to remove this way unless you<br />

have a 12-inch extension in your socket<br />

set. Some penetrating oil on the threads<br />

about an hour prior to removing the nuts<br />

and the use <strong>of</strong> a box-end wrench help<br />

avoid damaged knuckles. An open-end<br />

wrench slips <strong>of</strong>f too easily and there may<br />

not be enough room for a ratchet handle.<br />

Engine Mounts-<strong>Ford</strong> did us a big favor<br />

by designing the engine mounts for easy<br />

removal and installation. Each mount is a<br />

two-piece assembly. One half stays with<br />

the engine and the other with the frame<br />

or bod;. The two halves are held together<br />

with a through-bolt and nut. Depending<br />

on your vehicle, you'll have to judge now<br />

whether it will be easier to remove the<br />

bolts now, or from underneath after<br />

you've raised your car. One hitch is-if<br />

you have a <strong>351M</strong>/<strong>400</strong> or 460 in a truck,<br />

you'll have to remove the insulator or<br />

rubber portion <strong>of</strong> the engine mount.<br />

You'll also have to remove the vertical<br />

bolts on the frame-side <strong>of</strong> the insulators.<br />

This has to be done because the engine<br />

can't be lifted high enough to clear the<br />

engine mounts and disengage from the<br />

transmission due to interference at the<br />

firewall. This is the most difficult por-<br />

l NSU LATOR<br />

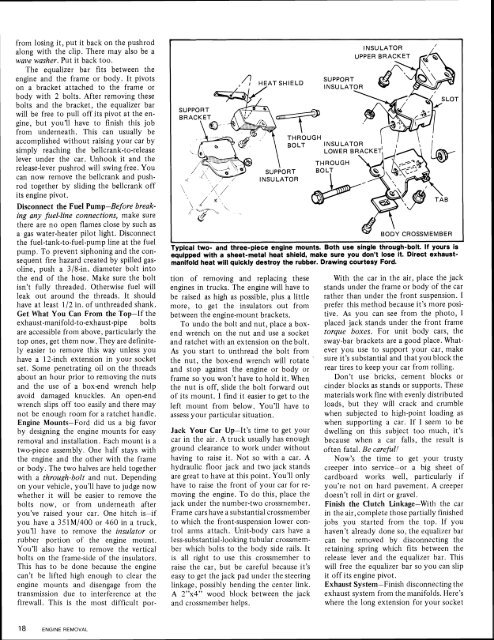

Typical two- and three-piece engine mounts. Both use single through-bolt. If yours is<br />

equipped with a sheet-metal heat shield, make sure you don't lose it. Direct exhaustmanifold<br />

heat will quickly destroy the rubber. Drawing courtesy <strong>Ford</strong>.<br />

tion <strong>of</strong> removing and replacing these<br />

engines in trucks. The engine will have to<br />

be raised as high as possible, plus a little<br />

more, to get the insulators out from<br />

between the engine-mount brackets.<br />

<strong>To</strong> undo the bolt and nut, place a boxend<br />

wrench on the nut and use a socket<br />

and ratchet with an extension on the bolt.<br />

As you start to unthread the bolt from<br />

the nut, the box-end wrench will rotate<br />

and stop against the engine or body or<br />

frame so you won't have to hold it. When<br />

the nut is <strong>of</strong>f, slide the bolt forward out<br />

<strong>of</strong> its mount. I find it easier to get to the<br />

left mount from below. You'll have to<br />

assess your particular situation.<br />

Jack <strong>Your</strong> Car Up-It's time to get your<br />

car in the air. A truck usually has enough<br />

ground clearance to work under without<br />

having to raise it. Not so with a car. A<br />

hydraulic floor jack and two jack stands<br />

are great to have at this point. You'll only<br />

have to raise the front <strong>of</strong> your car for removing<br />

the engine. <strong>To</strong> do this, place the<br />

jack under the number-two crossmember.<br />

Frame cars have a substantial crossmember<br />

to which the front-suspension lower control<br />

arms attach. Unit-body cars have a<br />

less-substantial-looking tubular crossmember<br />

which bolts to the body side rails. It<br />

is all right to use this crossmember to<br />

raise the car, but be careful because it's<br />

easy to get the jack pad under the steering<br />

linkage, possibly bending the center link.<br />

A 2"x4" wood block between the jack<br />

and crossmember helps.<br />

With the car in the air, place the jack<br />

stands under the frame or body <strong>of</strong> the car<br />

rather than under the front suspension. I<br />

prefer this method because it's more positive.<br />

As you can see from the photo, I<br />

placed jack stands under the front frame<br />

torque boxes. For unit body cars, the<br />

sway-bar brackets are a good place. Whatever<br />

you use to support your car, make<br />

sure it's substantial and that you block the<br />

rear tires to keep your car from rolling.<br />

Don't use bricks, cement blocks or<br />

cinder blocks as stands or supports. These<br />

materials work fine with evenly distributed<br />

loads, but they will crack and crumble<br />

when subjected to high-point loading as<br />

when supporting a car. If I seem to be<br />

dwelling on this subject too much, it's<br />

because when a car falls, the result is<br />

<strong>of</strong>ten fatal. Be careful!<br />

Now's the time to get your trusty<br />

creeper into service-or a big sheet <strong>of</strong><br />

cardboard works well, particularly if<br />

you're not on hard pavement. A creeper<br />

doesn't roll in dirt or gravel.<br />

Finish the Clutch Linkage-With the car<br />

in the air, complete those partially finished<br />

jobs you started from the top. If you<br />

haven't already done so, the equali~er bar<br />

can be removed by disconnecting the<br />

retaining spring which fits between the<br />

release lever and the equalizer bar. This<br />

will free the equalizer bar so you can slip<br />

it <strong>of</strong>f its engine pivot.<br />

Exhaust System-Finish disconnecting the<br />

exhaust system from the manifolds. Here's<br />

where the long extension for your socket<br />

/<br />

/ I