How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

I --<br />

, %:-.:I<br />

'-<br />

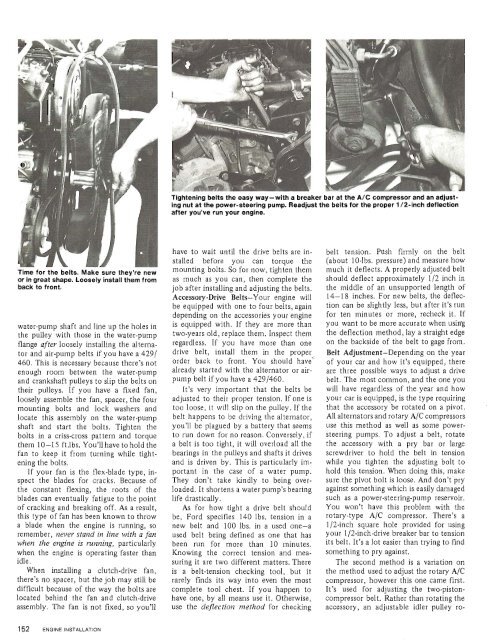

Tightening belts the easy way-with a breaker bar at the A/C compressor and an adjusting<br />

nut at the power-steering pump. Readjust the belts for the proper 1/2-Inch deflection<br />

after you've run your engine.<br />

I<br />

- have to wait until the drive belts are in- belt tension. Posh firmly on the belt<br />

L<br />

stalled before you can torque the (about 10-lbs. pressure) and measure how<br />

Time for the belts. Make sure they,re new mounting bolts. So for now, tighten them much it deflects. A properly adjusted belt<br />

or in great shape. Loosely install them from as much as you can, then complete the should deflect approximately 112 inch in<br />

back to front. job after installing and adjusting the belts. the middle <strong>of</strong> an unsupported length <strong>of</strong><br />

Accessory-Drive Belts-<strong>Your</strong> engine will 14-18 inches. For new belts, the deflecbe<br />

equipped with one t~ four belts, again tion can be slightly less, but after it's run<br />

depending on the accessories your engine for ten minutes or more, recheck it. If<br />

water-pump shaft and line up the holes in is equipped with. If they are more than You want to be more accurate when usin'g<br />

the pulley with those in the water-pump two-years old, replace them. Inspect them the deflection method, lay a straight edge<br />

flange after loosely installing the alterna- regardless. If you have more than one on the backside <strong>of</strong> the belt to gage from.<br />

tor and air-pump belts if you have a <strong>429</strong>1 drive belt, install them in the proper, Belt Adjustment-Depending on the year<br />

460, This is necessary because there's not order back to front. YOU should have' <strong>of</strong> your car and how it's equipped, there<br />

enough room between the water-pump already started with the alternator or air- are three possible ways to adjust a drive<br />

and crankshaft pulleys to slip the belts on Pump belt if you have a <strong>429</strong>1460. belt. The most common, and the one you<br />

their pulleys. If you have a futed fan, It's very important that the belts be will have regardless <strong>of</strong> the year and how<br />

loosely assemble the fan, spacer, the four adjusted to their proper tension. If one is your car is equipped, is the type requiring<br />

mounting bolts and lock washers and too loose, it will slip on the pulley. If the that the accessory be rotated on a pivot.<br />

locate this assembly on the water-pump belt happens to be driving the alternator, All alternators and rotary A/C compressors<br />

shaft and start the bolts. Tighten the you'll be plagued by a battery that seems use this method as well as some powerbolts<br />

in a criss-cross pattern and torque to run down for no reason. Conversely, if steering pumps. <strong>To</strong> adjust a belt, rotate<br />

them 10-1 5 ft.lbs. You'll have to hold the a belt is too tight, it will overload all the the accessory with a pry bar or large<br />

fan to keep it from turning while tight- bearings in the pulleys and shafts it drives screwdriver to hold the belt in tension<br />

ening the bolts. and is driven by. This is particularly im- while you tighten the adjusting bolt to<br />

If your fan is the flex-blade type, in- portant in the case <strong>of</strong> a water pump. hold this tension. When doing this, make<br />

spect the blades for cracks. Because <strong>of</strong> They don't take kindly to being over- sure the pivot bolt is loose. And don't pry<br />

the constant flexing, the roots <strong>of</strong> the loaded. It shortens a water pump's bearing against something which is easily damaged<br />

blades can eventually fatigue to the point life drastically. such as a power-steering-pump reservoir.<br />

<strong>of</strong> cracking and breaking <strong>of</strong>f. As a result, As for how tight a drive belt should You won't have this problem with the<br />

this type <strong>of</strong> fan has been known to throw be, <strong>Ford</strong> specifies 140 lbs, tension in a rotary-type A/C compressor. There's a<br />

a blade when the engine is running, so new belt and 100 lbs. in a used one-a 112-inch square hole provided for using<br />

remember, never stand in line with a fan used belt being defined as one that has <strong>Your</strong> 112-inch-drive breaker bar to tension<br />

when the engine is running, particularly been run for more than 10 minutes. its belt. It's a lot easier than trying to find<br />

when the engine is operating faster than Knowing the correct tension and mea- something to pry against.<br />

idle. suring it are two different matters. There The second method is a variation on<br />

When installing a clutch-drive fan, is a belt-tension checking tool, but it the method used to adjust the rotary A/C<br />

there's no spacer, but the job may still be rarely finds its way into even the most compressor, however this one came first.<br />

difficult because <strong>of</strong> the way the bolts are complete tool chest. If you happen to It's used for adjusting the two-pistonlocated<br />

behind the fan and clutch-drive have one, by all means use it. Otherwise, compressor belt. Rather than rotating the<br />

assembly. The fan is not fixed, so you'll use the dejlectiorz method for checking accessory, an adjustztble idler pulley ro-