How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Object here is to engage converter drive lugs with the flexplate or standard-transmission<br />

input shaft with the clutch and the engine dowels with the transmission housing, then to<br />

get one bolt started. It sometimes takes a lot <strong>of</strong> wrenching and joggling until this task is<br />

accomplished, but let's not give up now.<br />

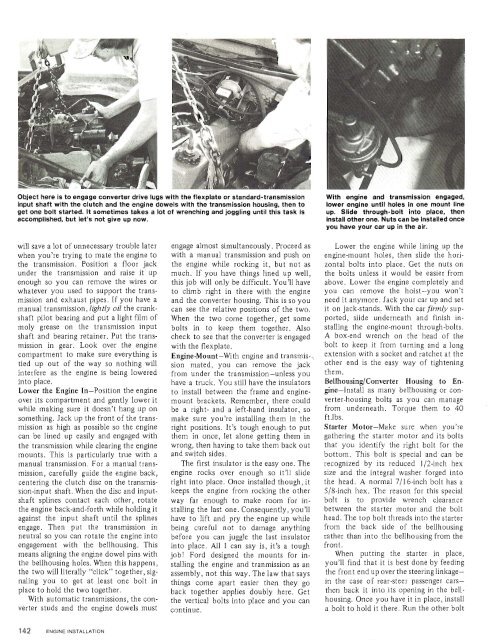

With engine and transmission engaged,<br />

lower engine until holes in one mount line<br />

up. Slide through-bolt into place, then<br />

install other one. Nuts can be installed once<br />

you have your car up in the air.<br />

will save a lot <strong>of</strong> unnecessary trouble later<br />

when you're trying to mate the engine to<br />

the transmission. Position a floor jack<br />

under the transmission and raise it up<br />

enough so you can remove the wires or<br />

whatever you used to support the transmission<br />

and exhaust pipes. If you have a<br />

manual transmission, lightly oil the crankshaft<br />

pilot bearing and put a light film <strong>of</strong><br />

moly grease on the transmission input<br />

shaft and bearing retainer. Put the transmission<br />

in gear. Look over the engine<br />

compartment to make sure everything is<br />

tied up out <strong>of</strong> the way so nothing will<br />

interfere as the engine is being lowered<br />

into place.<br />

Lower the Engine In-Position the engine<br />

over its compartment and gently lower it<br />

while making sure it doesn't hang up on<br />

something. Jack up the front <strong>of</strong> the transmission<br />

as high as possible so the engine<br />

can be lined up easily and engaged with<br />

the transmission while clearing the engine<br />

mounts. This is particularly true with a<br />

manual transmission. For a manual transmission,<br />

carefully guide the engine back,<br />

centering the clutch disc on the transmission-input<br />

shaft. When the disc and inputshaft<br />

splines contact each other, rotate<br />

the engine back-and-forth while holding it<br />

against the input shaft until the splines<br />

engage. Then put the transmission in<br />

neutral so you can rotate the engine into<br />

engagement with the bellhousing. This<br />

means aligning the engine dowel pins with<br />

the bellhousing holes. When this happens,<br />

the two will literally "click" together, signaling<br />

you to get at least one bolt in<br />

place to hold the two together.<br />

With automatic transmissions, the converter<br />

studs and the engine dowels must<br />

engage almost simultaneously. Proceed as<br />

with a manual transmission and push on<br />

the engine while rocking it, but not as<br />

much. If you have things lined up well,<br />

this job will only be difficult. You'll have<br />

to climb right in there with the engine<br />

and the converter housing. This is so you<br />

can see the relative positions <strong>of</strong> the two.<br />

When the two come together, get some<br />

bolts in to keep them together. Also<br />

check to see that the converter is engaged<br />

with the flexplate.<br />

Engine-Mount-With engine and transmis-;<br />

sion mated, you can remove the jack<br />

from under the transmission-unless you<br />

have a truck. You still have the insulators<br />

to install between the frame and enginemount<br />

brackets. Remember, there could<br />

be a right- and a left-hand insulator, so<br />

make sure you're installing them in the<br />

right positions. It's tough enough to put<br />

them in once, let alone getting them in<br />

wrong, then having to take them back out<br />

and switch sides.<br />

The first insulator is the easy one. The<br />

engine rocks over enough so it'll slide<br />

right into place. Once installed though, it<br />

keeps the engine from rocking the other<br />

way far enough to make room for installing<br />

the last one. consequently, you'll<br />

have to lift and pry the engine up while<br />

being careful not to damage anything<br />

before you can juggle the last insulator<br />

into place. All I can say is, it3 a tough<br />

job! <strong>Ford</strong> designed the mounts for installing<br />

the engine and tranmission as an<br />

assembly, not this way. The law that says<br />

things come apart easier then they go<br />

back together applies doubly here. Get<br />

the vertical bolts into place and you can<br />

continue.<br />

Lower the engine while lining up the<br />

engine-mount holes, then slide the horizontal<br />

bolts into place. Get the nuts on<br />

the bolts unless it would be easier from<br />

above. Lower the engine completely and<br />

you can remove the hoist-you won't<br />

need it anymore. Jack your car up and set<br />

it on jack-stands, With the carfirmly supported,<br />

slide underneath and finish installing<br />

the engine-mount through-bolts.<br />

A box-end wrench on the head <strong>of</strong> the<br />

bolt to keep. it from turning and a long<br />

extension with a socket and ratchet at the<br />

other end is the easy way <strong>of</strong> tightening<br />

them.<br />

Bellhousing/Converter Housing to En-<br />

gine-Install as many bellhousing or converter-housing<br />

bolts as you can manage<br />

from underneath. <strong>To</strong>rque them to 40<br />

ft.lbs.<br />

Starter Motor-Make sure when you're<br />

gathering the starter motor and its bolts<br />

that you identify the right bolt for the<br />

bottom. This bolt is special and can be<br />

recognized by its reduced 112-inch hex<br />

size and the integral washer forged into<br />

the head. A normal 7116-inch bolt has a<br />

518-inch hex. The reason for this special<br />

bolt is to provide wrench clearance<br />

between the starter motor and the bolt<br />

head. The top bolt threads into the starter<br />

from the back side <strong>of</strong> the bellhousing<br />

rather than into the bellhousing from the<br />

front.<br />

When putting the starter in place,<br />

you'll find that it is best done by feeding<br />

the front end up over the steeringlinkagein<br />

the case <strong>of</strong> rear-steer passenger carsthen<br />

back it into its opening in the bellhousing.<br />

Once you have it in place, install<br />

a bolt to hold it there. Run the other bolt