How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Cross-hatch pattern <strong>of</strong> a freshly honed block. The block must receive a final cleaning to<br />

remove the abrasive grit and metal cuttings. A scrub brush used vigorously with laundry<br />

detergent and hot water works well. After the bores are cleaned and rinsed, they should<br />

be dried and oiled immediately.<br />

Consequently, even though your<br />

engine was hot-tanked by the machinist,<br />

enlist the use <strong>of</strong> a stiff-bristle brush,<br />

laundry detergent and warm water to<br />

satisfy yourself that the engine is clean.<br />

This, combined with a generous amount<br />

<strong>of</strong> elbow grease, will give you a superclean<br />

block. Finish by wiping the bores<br />

with a white paper towel. It should stay<br />

clean and white if you've gotten the bores<br />

clean. If not, clean them again.<br />

After you've finished the scrubbing<br />

and rinsing, don't let the block air-dry.<br />

The newly machined surfaces will rust<br />

very quickly. If you have compressed<br />

air, use it to blow-dry the block. It's<br />

best because you don't have to touch<br />

the block and the compressed air will<br />

blow water out <strong>of</strong> every little corner. The<br />

next best thing to use is paper towelsnot<br />

cloth rags or towels. They spread<br />

lint that won't dissolve like that from a<br />

paper towel. Immediately after you've<br />

gotten the block dried <strong>of</strong>f, get your spray<br />

can <strong>of</strong> oil and coat all the machined<br />

surfaces. CRC and WD-40 displace<br />

water rather than trapping it. This will<br />

protect the block against rust, but will<br />

also turn it into a big dust collector.<br />

Consequently, you'll have to keep it<br />

covered. Now that you're finished with<br />

the block until assembly time, store it by<br />

standing it on its rear face. Cover it with<br />

a plastic trash bag until you're ready for<br />

final engine assembly.<br />

component. As a result, it's rare that a<br />

crankshaft cannot be reused for a rebuild.<br />

They very rarely ever wear to the<br />

point <strong>of</strong> having to be replaced. What<br />

usually happens is the journals are<br />

damaged from a lack <strong>of</strong> lubrication, but<br />

mostly from very dirty oil. Usually this<br />

damage can be repaired. Even dirty oil<br />

usually doesn't change a crank's journals,<br />

but if the dirt particles get too big and<br />

numerous, it will. The one thing that can<br />

render a crankshaft useless is mechanical<br />

damage caused when another component<br />

in an engine breaks-such as a rod bolt:df<br />

an engine isn't shut <strong>of</strong>f immediately or if<br />

this occurs at high RPM, the crank and<br />

many other expensive components will<br />

have to be replaced also.<br />

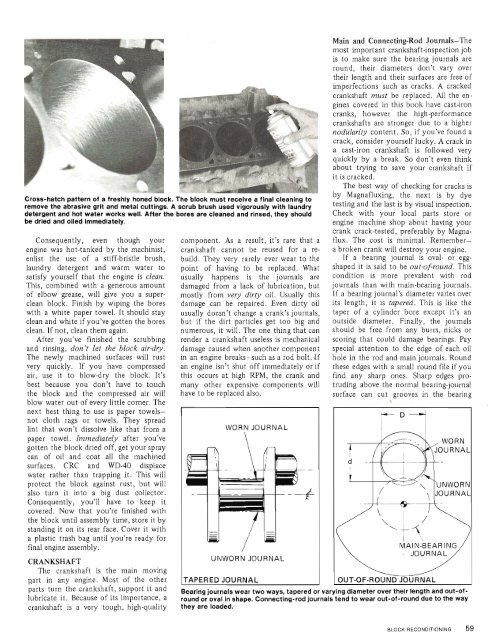

WORN JOURNAL<br />

- -<br />

- -<br />

- -<br />

-<br />

1 -+<br />

Main and Connecting-Rod Journals-The<br />

most important crankshaft-inspection job<br />

is to make sure the bearing journals are<br />

round, their diameters don't vary over<br />

their length and their surfaces are free <strong>of</strong><br />

imperfections such as cracks. A cracked<br />

crankshaft must be replaced. All the engines<br />

covered in this book have cast-iron<br />

cranks, however the high-performance<br />

crankshafts are stronger due to a higher<br />

nodularity content. So, if you've found a<br />

crack, consider yourself lucky. A crack in<br />

a cast-iron crankshaft is followed very<br />

quickly by a break. So don't even think<br />

about trying to save your crankshaft if<br />

it is cracked.<br />

The best way <strong>of</strong> checking for cracks is<br />

by Magnafluxing, the next is by dye<br />

testing and the last is by visual inspection.<br />

Check with your local parts store or<br />

engine machine shop about having your<br />

crank crack-tested, preferably by Magnaflux.<br />

The cost is minimal. Remembera<br />

broken crank will destroy your engine.<br />

If a bearing journal is oval- or eggshaped<br />

it is said to be out-<strong>of</strong>-round. This<br />

condition is more prevalent with rod<br />

journals than with main-bearing journals.<br />

If a bearing journal's diameter varies over<br />

its length, it is tapered. This is like the<br />

taper <strong>of</strong> a cylinder bore except it's an<br />

outside diameter. Finally, the journals<br />

should be free from any burrs, nicks or<br />

scoring that could damage bearings. Pay<br />

special attention to the edge <strong>of</strong> each oil<br />

hole in the rod and main journals. Round<br />

these edges with a small round file if you<br />

find any sharp ones. Sharp edges protruding<br />

above the normal bearing-journal<br />

surface can cut grooves in the bearing<br />

-- D --<br />

I<br />

I<br />

CRANKSHAFT<br />

UNWORN JOURNAL<br />

The crankshaft is the main moving<br />

part in any engine. Most <strong>of</strong> the other TAPERED JOURNAL<br />

OUT-OF-ROUND JOURNAL<br />

parts turn the it and Bearing journals wear two ways, tapered or varying diameter over their length and out-<strong>of</strong>lubricate<br />

it. Because <strong>of</strong> its importance, a round or oval in shape. Connecting-rod journals tend to wear out-<strong>of</strong>-round due to the way<br />

crankshaft is a very tough, high-quality they are loaded.<br />

BLOCK RECONDITIONING 59