How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

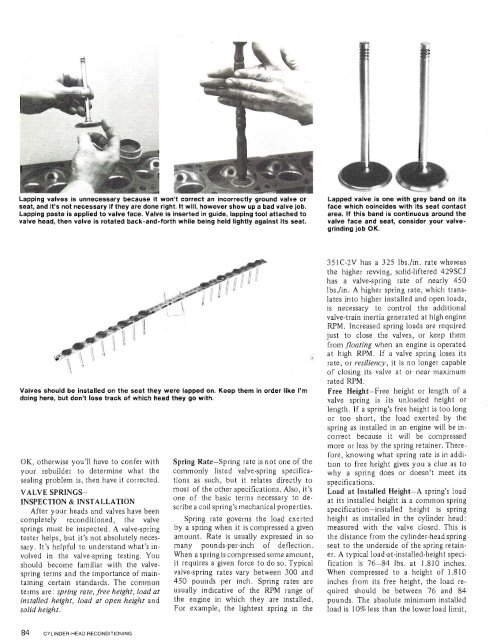

Lapping valves is unnecessary because it won't correct an incorrectly ground valve or<br />

seat, and it's not necessary it they are done right. It will, however show up a bad valve job.<br />

Lapping paste is applied to valve face. Valve is inserted in guide, lapping tool attached to<br />

valve head, then valve is rotated back-and-forth while being held lightly against its seat.<br />

Lapped valve is one with grey band on its<br />

face which coincides with its seat contact<br />

area. If this band is continuous around the<br />

valve face and seat, consider your valvegrinding<br />

job OK.<br />

Valves should be installed on the seat they were lapped on. Keep them in order like I'm<br />

dolng here, but don't lose track <strong>of</strong> which head they go wlth.<br />

OK, otherwise you'll have to confer with<br />

your rebuilder to determine what the<br />

sealing problem is, then have it corrected.<br />

VALVE SPRINGS-<br />

INSPECTION & INSTALLATION<br />

After your heads and valves have been<br />

completely reconditioned, the valve<br />

springs must be inspected. A valve-spring<br />

tester helps, but it's not absolutely necessary.<br />

It's helpful to understand what's involved<br />

in the valve-spring testing. You<br />

should become familiar with the valvespring<br />

terms and the importance <strong>of</strong> maintaining<br />

certain standards. The common<br />

terms are: spring rate, free height, load at<br />

installed height, load at open height and<br />

solid height.<br />

Spring Rate-Spring rate is not one <strong>of</strong> the<br />

commonly listed valve-spring specifications<br />

as such, but it relates directly to<br />

most <strong>of</strong> the other specifications. Also, it's<br />

one <strong>of</strong> the basic terms necessary to describe<br />

a coil spring's mechanical properties.<br />

Spring rate governs the load exerted<br />

by a spring when it is compressed a given<br />

amount. Rate is usually expressed in so<br />

many pounds-per-inch <strong>of</strong> deflection.<br />

When a spring is compressed some amount,<br />

it requires a given force to do so. Typical<br />

valve-spring rates vary between 300 and<br />

450 pounds per inch. Spring rates are<br />

usually indicative <strong>of</strong> the RPM range <strong>of</strong><br />

the engine in which they are installed.<br />

For example, the lightest spring in the<br />

<strong>351C</strong>-2V has a 325 lbs./in. rate whereas<br />

the higher rewing, solid-liftered <strong>429</strong>SCJ<br />

has a valve-spring rate <strong>of</strong> nearly 450<br />

Ibs./in. A higher spring rate, which translates<br />

into higher installed and open loads,<br />

is necessary to control the additional<br />

valve-train inertia generated at high engine<br />

RPM. Increased spring loads are required<br />

just to close the valves, or keep them<br />

from floating when an engine is operated<br />

at high RPM. If a valve spring loses its<br />

rate, or resiliency, it is no longer capable<br />

<strong>of</strong> closing its valve at or near maximum<br />

rated RPM.<br />

Free Height-Free height or length <strong>of</strong> a<br />

valve spring is its unloaded height or<br />

length. If a spring's free height is too long<br />

or too short,. the load exerted by the<br />

spring as installed in an engine will be incorrect<br />

because it will be compressed<br />

more or less by the spring retainer. Therefore,<br />

knowing what spring rate is in addition<br />

to free height gives you a clue as to<br />

why a spring does or doesn't meet its<br />

specifications.<br />

Load at Installed Height-A spring's load<br />

at its installed height is a common spring<br />

specification-installed height is spring<br />

height as installed in the cylinder head:<br />

measured with the valve closed. This is<br />

the distance from the cylinder-head spring<br />

seat to the underside <strong>of</strong> the spring retainer.<br />

A typical load-at-installed-height specification<br />

is 76-84 lbs. at 1.810 inches.<br />

When compressed to a height <strong>of</strong> 1.810<br />

inches from its free height, the load required<br />

should be between 76 and 84<br />

pounds. The absolute minimum installed<br />

load is 10% less than the lower load limit,