How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

anything from a cardboard box to a piece<br />

<strong>of</strong> lath with 16 holes drilled in it.<br />

CLEANUP AND INSPECTION<br />

Scrape, Scrape, Scrape-Time for the old<br />

gasket scraper and elbow grease again. As<br />

you probably found when scraping your<br />

block deck surfaces, head gaskets seem to<br />

have "grown to" the metal. If you had<br />

your heads hot-tanked, the job will be<br />

much easier. Clean all gasket surfaces,<br />

the head-gasket, intake-manifold and<br />

rocker-arm-cover sealing surfaces <strong>of</strong> all<br />

old gasket material. Using a round file,<br />

clean the head-to-block water passages<br />

<strong>of</strong> all deposits.<br />

It's time to misuse a screwdriver or a<br />

small chisel. Scrape the carbon deposits<br />

from the combustion chambers and exhaust<br />

and intake ports. After the heavy<br />

work is done, finish the job with a wire<br />

brush. This will put a light polish on the<br />

surface so you can spot any cracks which<br />

may have developed in the combustion<br />

chambers, particularly around the valveseat<br />

area. If you do find cracks in any <strong>of</strong><br />

these areas, don't junk the head just yet.<br />

Take it to your engine machinist to see<br />

if it can be repaired by pinning. If it<br />

can't, then it's junk. Even though it may<br />

be repairable by welding, chances are this<br />

cost will exceed the cost <strong>of</strong> replacement.<br />

Head-Surface Flatness-Because cylinder<br />

heads are subjected to extreme heat, combustion<br />

and compression loads and are<br />

structurally weak compared to an engine<br />

block, they are susceptible to warping, as<br />

well as cracking. Excessive mismatch between<br />

block and deck surfaces causes<br />

combustion or coolant leakages, consequently<br />

those surfacesmust beflat. Check<br />

the head-gasket surfaces with a straightedge<br />

and feeler gages. Set the straightedge<br />

lengthwise and diagonally across the<br />

head in both directions. Measure clearances<br />

which appear between the head and<br />

the straight-edge with your feeler gages.<br />

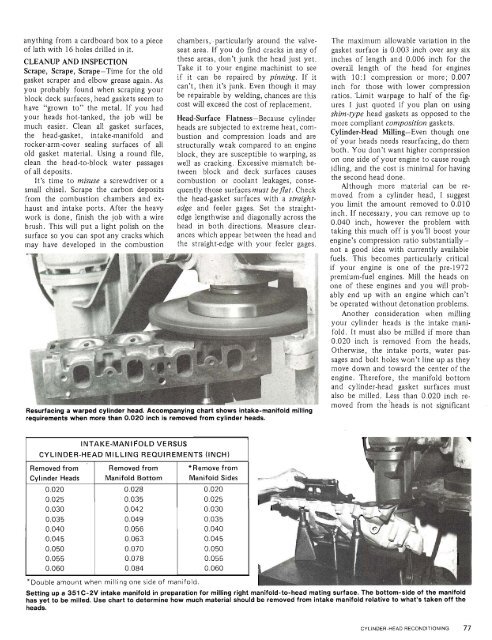

Resurfacing a warped cylinder head. Accompanying chart shows intake-manifold milling<br />

requirements when more than 0.020 inch is removed from cylinder heads.<br />

The maximum allowable variation in the<br />

gasket surface is 0.003 inch over any six<br />

inches <strong>of</strong> length and 0.006 inch for the<br />

overall length <strong>of</strong> the head for engines<br />

with 10:l compression or more; 0.007<br />

inch for those with lower compression<br />

ratios. .Limit warpage to half <strong>of</strong> the figures<br />

I just quoted if you plan on using<br />

shim-type head gaskets as opposed to the<br />

more compliant composition gaskets.<br />

Cylinder-Head Milling-Even though one<br />

<strong>of</strong> your heads needs resurfacing, do them<br />

both. You don't want higher compression<br />

on one side <strong>of</strong> your engine to cause rough<br />

idling, and the cost is minimal for having<br />

the second head done.<br />

Although more material can be removed<br />

from a cylinder head, I suggest<br />

you limit the amount removed to 0.010<br />

inch. If necessary, you can remove up to<br />

0.040 inch, however the problem with<br />

taking this much <strong>of</strong>f is you'll boost your<br />

engine's compression ratio substantiallynot<br />

a good idea with currently available<br />

fuels. This becomes particularly critical<br />

if your engine is one <strong>of</strong> the pre-1972<br />

premium-fuel engines. Mill the heads on<br />

one <strong>of</strong> these engines and you will probably<br />

end up with an engine which can't<br />

be operated without detonation problems.<br />

Another consideration when milling<br />

your cylinder heads is the intake manifold.<br />

It must also be milled if more than<br />

0.020 inch is removed from the heads.<br />

Otherwise, the intake ports, water passages<br />

and bolt holes won't line up as they<br />

move down and toward the center <strong>of</strong> the<br />

engine. Therefore, the manifold bottom<br />

and cylinder-head gasket surfaces must<br />

also be milled. Less than 0.020 inch removed<br />

from the3heads is not significant<br />

INTAKE-MAN1 COLD VERSUS<br />

CYLINDER-HEAD MILLING REQUIREMENTS (INCH)<br />

Removed from<br />

Cylinder Heads<br />

0.020<br />

0.025<br />

0.030<br />

0.035<br />

0.040<br />

0.045<br />

0.050<br />

0.055<br />

0.060<br />

Removed from<br />

Manifold Bottom<br />

0.028<br />

0.035<br />

0.042<br />

0.049<br />

0.056<br />

0.063<br />

0.070<br />

0.078<br />

0.084<br />

*Remove from<br />

Manifold Sides<br />

0.020<br />

0.025<br />

0.030<br />

0.035<br />

0.040<br />

0.045<br />

0.050<br />

0.055<br />

0.060<br />

uble amount when milling one side <strong>of</strong> manifold.<br />

Setting up a 351 C-2V intake manifold in preparation for milling right manifold-to-head mating surface. The bottom-side <strong>of</strong> the manifold<br />

has yet to be milled. Use chart to determine how much material should be removed from intake manifold relative to what's taken <strong>of</strong>f the<br />

heads.<br />

CYLINDER-HEAD RECONDITIONING 77