How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

-<br />

Rather than removing teeth marks from the<br />

pin, take advantage <strong>of</strong> them. They'll help<br />

secure the pin in the new cam. So install<br />

the pin end-for-end by driving it into place<br />

with a punch and hammer. When it bottoms,<br />

it's installed.<br />

range shown in the chart, you'll obviously<br />

use standard bearings. <strong>How</strong>ever, if they<br />

mike some amount less, you'll need the<br />

same amount <strong>of</strong> undersize bearing as the<br />

difference from the standard nominal<br />

bearing size. Simply put, if a <strong>351C</strong> mainbearing<br />

journal mikes 2.7478 inches, the<br />

proper undersize bearing to use is 2.788<br />

- 2.7478 = 0.010-inch undersize. So, to<br />

determine if and how much <strong>of</strong> an undersize<br />

bearing you need, subtract the diameter<br />

<strong>of</strong> your bearing journals from the<br />

standard nominal bearing-journal diameter.<br />

There are two types <strong>of</strong> rear-main bearing<br />

seals you can install: the rope and the<br />

split-lip types. A rope seal will probably<br />

be included in your gasket set. It consists<br />

<strong>of</strong> two pieces <strong>of</strong> graphite-impregnated<br />

rope. The split-lip seal is made from neoprene,<br />

also in two pieces. If you want this<br />

seal instead <strong>of</strong> the rope type, you'll have<br />

to lay out another three bucks or so. I<br />

like the split-lip seal because a rope seal<br />

is more difficult to install. And, the rope<br />

seal creates more friction, as initially<br />

installed, meaning the torque required to<br />

turn the crank during assembly will<br />

be approximately 10 ft. lbs. more.<br />

<strong>How</strong>ever, the relative effectiveness <strong>of</strong><br />

the two seals is the same. Also, the<br />

rope seal's initial friction drops <strong>of</strong>f<br />

considerably after the first few minutes<br />

<strong>of</strong> engine operation.<br />

Install the Main-Bearing Inserts-With the<br />

engine block upside down, wipe the bearing<br />

bores clean so there won't be any dirt<br />

trapped behind the bearing inserts. Wipe<br />

them clean using paper towels and a<br />

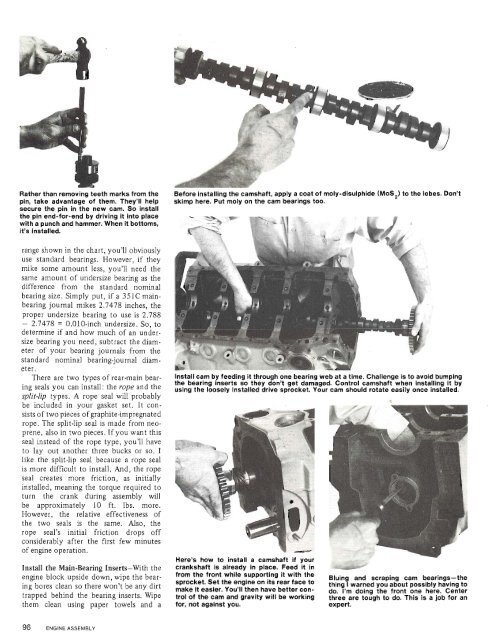

Before installing the camshaft, apply a coat <strong>of</strong> moly-disulphide (MoS,) to the lobes. Don't<br />

skimp here. Put moly on the cam bearings too.<br />

Install cam by feeding it through one bearing web at a time. Challenge is to avoid bumping<br />

the bearing inserts so they don't get damaged. Control camshaft when installing it by<br />

using the loosely Installed drive sprocket. <strong>Your</strong> cam should rotate easily once installed.<br />

Here's how to install a camshaft If your<br />

crankshaft is already in place. Feed it in<br />

from the front while supporting it with the<br />

sprocket. Set the engine on its rear face to<br />

make It easier. You'll then have better control<br />

<strong>of</strong> the cam and gravity will be working<br />

for, not against you.<br />

3<br />

Bluing and scraping cam bearings-the<br />

thing I warned you about possibly having to<br />

do. I'm doing the front one here. Center<br />

three are tough to do. This is a job for an<br />

expert.