How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

them; they'll tell you a story. Bearing<br />

inserts are made from plated copperlead<br />

alloy or lead-based babbit, both<br />

on a steel backing or shell. If your<br />

engine has a lot <strong>of</strong> accessories such as<br />

power steering and air conditioning,<br />

the front top bearing should be worn<br />

more than the other bearings due to<br />

the higher vertical load imposed on the<br />

crankshaft and bearing by the drive<br />

belts. This wear is normal because <strong>of</strong><br />

the way the crankshaft is loaded and<br />

should not be a cause for any concern.<br />

For the same reason, wear may also<br />

show up on the bottom <strong>of</strong> the center<br />

bearings, particularly at the second<br />

and third journals. If the bearings are I<br />

copper-lead type, a copper color will<br />

show evenly through the tin plating.<br />

This makes it easy to distinguish wear<br />

because <strong>of</strong> the contrasting colors <strong>of</strong><br />

the tin and copper. As for the leadbase<br />

bearings, it's more difficult to<br />

distinguish wear because <strong>of</strong> the similar<br />

colors <strong>of</strong> the bearing and backing.<br />

You should be concerned about<br />

uneven wear from front-to-back on the<br />

total circumference <strong>of</strong> the bearing<br />

(top and bottom), scratches in the<br />

bearing surface and a wiped bearing<br />

surface. The first condition indicates<br />

the bearing journal is tapered, its diameter<br />

is not constant from one end to<br />

the other, causing uneven bearing and<br />

journal loading and uneven wear.<br />

Scratches in the bearing surface mean<br />

foreign material in the oil passed between<br />

the bearing and crankshaft<br />

journal. ~h~ usual cause <strong>of</strong> this is<br />

dirty oil and an oil filter which clogged, 1<br />

1 resulting in the filter being bypassed<br />

and the oii going through the engine<br />

unfiltered. A wiped bearing surface is<br />

usually caused by the journal not receiving<br />

adequate lubrication. This can<br />

be caused by periodic loss <strong>of</strong> oil pressure<br />

from a low oil level in the crankcase,<br />

a clogged oil passage or a malfunctioning<br />

oil pump. All these things have<br />

to be checked and remedied when the<br />

problem is found. Also, any problem<br />

, you may find with the bearings means<br />

there may be damage to the crankshaft.<br />

Consequently you should pay particular<br />

attention to the crank journals<br />

which had bearing damage to see if<br />

there is corresponding damage to the<br />

crank.<br />

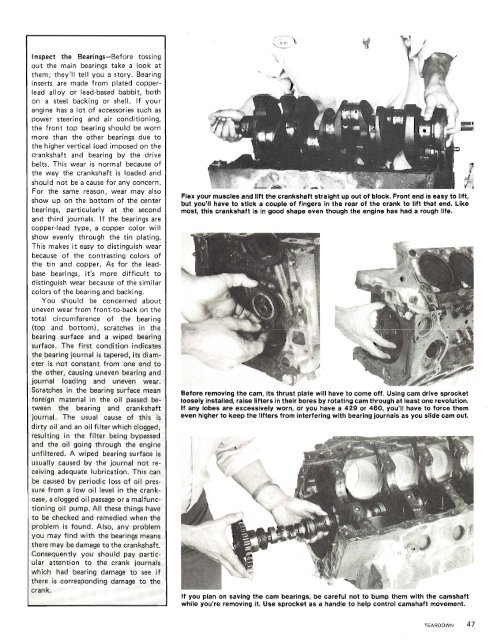

Flex your muscles and llft the crankshaft straight up out <strong>of</strong> block. Front end is easy to lift,<br />

but you'll have to stick a couple <strong>of</strong> flngers in the rear <strong>of</strong> the crank to lift that end. Llke<br />

most, this crankshaft is in good shape even though the engine has had a rough Ilfe.<br />

Before removing the cam, its thrust plate will have to come <strong>of</strong>f. Using cam drive sprocket<br />

loosely installed, raise lifters in their bores by rotating cam through at least one revolution.<br />

If any lobes are excessively worn, or you have a <strong>429</strong> or 460, you'll have to force them<br />

even higher to keep the lifters from interfering with bearing journals as you slide cam out.<br />

, If you plan on saving the cam bearings, be careful not to bump them with the camshaft<br />

while you're removing it. Use sprocket as a handle to help control camshaft movement.<br />

TEARDOWN 47