How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

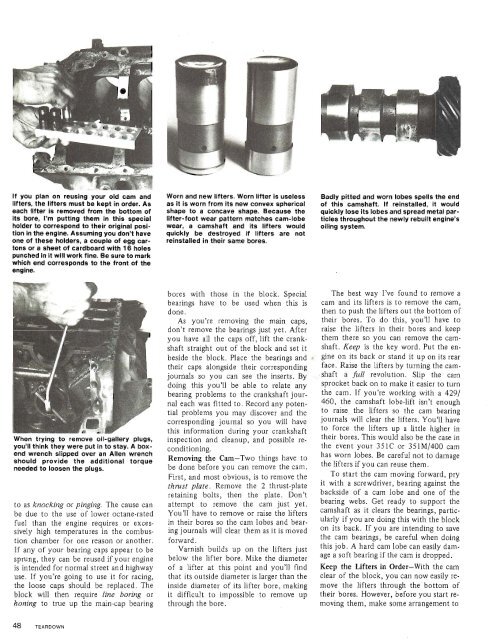

If you plan on reusing your old cam and<br />

lifters, the lifters must be kept in order. As<br />

each llfter is removed from the bottom <strong>of</strong><br />

its bore, I'm putting them In this special<br />

holder to correspond to their original position<br />

in the engine. Assuming you don't have<br />

one <strong>of</strong> these holders, a couple <strong>of</strong> egg cartons<br />

or a sheet <strong>of</strong> cardboard with 16 holes<br />

punched in it will work flne. Be sure to mark<br />

which end corresponds to the front <strong>of</strong> the<br />

engine.<br />

Worn and new lifters. Worn lifter is useless<br />

as it is worn from its new convex spherical<br />

shape to a concave shape. Because the<br />

lifter-foot wear pattern matches cam-lobe<br />

wear, a camshaft and its lifters would<br />

quickly be destroyed If lifters are not<br />

reinstalled in their same bores.<br />

Badly pitted and worn lobes spells the end<br />

<strong>of</strong> this camshaft. If reinstalled, it would<br />

quickly lose its lobes and spread metal particles<br />

throughout the newly rebuilt engine's<br />

oiling system.<br />

When trying to remove oil-gallery plugs,<br />

you'll think they were put in to stay. A boxend<br />

wrench slipped over an Allen wrench<br />

should provide the additional torque<br />

needed to loosen the plugs.<br />

to as knocking or pinging. The cause can<br />

be due to the use <strong>of</strong> lower octane-rated<br />

fuel than the engine requires or excessively<br />

high temperatures in the combustion<br />

chamber for one reason or another.<br />

If any <strong>of</strong> your bearing caps appear to be<br />

sprung, they can be reused if your engine<br />

is intended for normal street and highway<br />

use. If you're going to use it for racing,<br />

the loose caps should be replaced. The<br />

block will then require line boring or<br />

honing to true up the main-cap bearing<br />

bores with those in the block. Special<br />

bearings have to be used when this is<br />

done.<br />

As you're removing the main caps,<br />

don't remove the bearings just yet. After<br />

you have all the caps <strong>of</strong>f, lift the crankshaft<br />

straight out <strong>of</strong> the block and set it<br />

beside the block. Place the bearings and<br />

their caps alongside their corresponding<br />

journals so you can see the inserts. By<br />

doing this you'll be able to relate any<br />

bearing problems to the crankshaft journal<br />

each was fitted to. Record any potential<br />

problems you may discover and the<br />

corresponding journal so you will have<br />

this information during your crankshaft<br />

inspection and cleanup, and possible reconditioning.<br />

Removing the Cam-Two things have to<br />

be done before you can remove the cam.<br />

First, and most obvious, is to remove the<br />

thrust plate. Remove the 2 thrust-plate<br />

retaining bolts, then the plate. Don't<br />

attempt to remove the cam just yet.<br />

You'll have to remove or raise the lifters<br />

in their bores so the cam lobes and bearing<br />

journals will clear them as it is moved<br />

forward.<br />

Varnish builds up on the lifters just<br />

below the lifter bore. Mike the diameter<br />

<strong>of</strong> a lifter at this point and you'll find<br />

that its outside diameter is larger than the<br />

inside diameter <strong>of</strong> its lifter bore, making<br />

it difficult to impossible to remove up<br />

through the bore.<br />

The best way I've found to remove a<br />

cam and its lifters is to remove the cam,<br />

then to push the lifters out the bottom <strong>of</strong><br />

their bores:<strong>To</strong> do this, you'll have to<br />

raise the lifters in their bores and keep<br />

them there so you can remove the camshaft.<br />

Keep is the key word. Put the engine<br />

on its back or stand it up on its rear<br />

face. Raise the lifters by turning the cam-<br />

.shaft a full revolution. Slip the cam<br />

sprocket back on to make it easier to turn<br />

the cam. If you're working with a <strong>429</strong>1<br />

460, the camshaft lobe-lift isn't enough<br />

to raise the lifters so the cam bearing<br />

journals will clear the lifters. You'll have<br />

to force the lifters up a little higher in<br />

their bores. This would also be the case in<br />

the event your <strong>351C</strong> or <strong>351M</strong>/<strong>400</strong> cam<br />

has worn lobes. Be careful not to damage<br />

the lifters if you can reuse them.<br />

<strong>To</strong> start the cam moving forward, pry<br />

it with a screwdriver, bearing against the<br />

backside <strong>of</strong> a cam lobe and one <strong>of</strong> the<br />

bearing webs. Get ready to support the<br />

camshaft as it clears the bearings, particularly<br />

if you are doing this with the block<br />

on its back. If you are intending to save<br />

the cam bearings, be careful when doing<br />

this job. A hard cam lobe can easily damage<br />

a s<strong>of</strong>t bearing if the cam is dropped.<br />

Keep the Lifters in Order-With the cam<br />

clear <strong>of</strong> the block, you can now easily remove<br />

the lifters through the bottom <strong>of</strong><br />

their bores. <strong>How</strong>ever, before you start removing<br />

them, make some arrangement to