How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

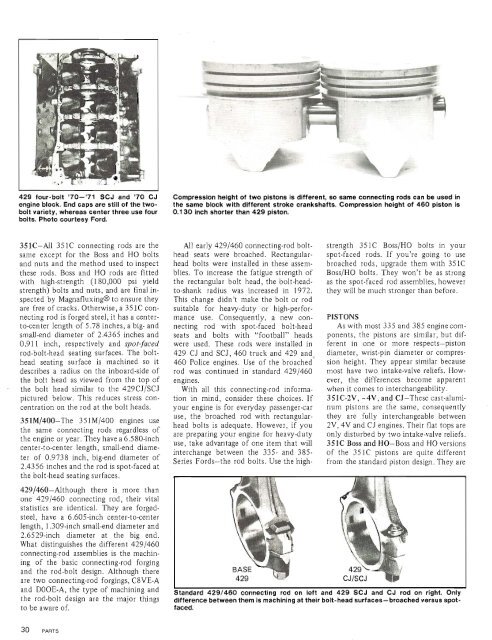

<strong>429</strong> four-bolt '70-'71 SCJ and '70 CJ Compression height <strong>of</strong> two pistons is different, so same connecting rods can be used in<br />

engine block. End caps are still <strong>of</strong> the two- the same block with different stroke crankshafts. Compression height <strong>of</strong> 460 piston is<br />

bolt variety, whereas center three use four 0.130 inch shorter than <strong>429</strong> piston.<br />

bolts. Photo courtesy <strong>Ford</strong>.<br />

<strong>351C</strong>-All <strong>351C</strong> connecting rods are the<br />

same except for the Boss and HO bolts<br />

and nuts and the method used to inspect<br />

these rods. Boss and HO rods are fitted<br />

with high-strength (180,000 psi yield<br />

strength) bolts and nuts, and are final inspected<br />

by MagnafluxingB to ensure they<br />

are free <strong>of</strong> cracks. Otherwise, a <strong>351C</strong> connecting<br />

rod is forged steel, it has a centerto-center<br />

length <strong>of</strong> 5.78 inches, a big- and<br />

small-end diameter <strong>of</strong> 2.4365 inches and<br />

0.91 1 inch, respectively and spot-faced<br />

rod-bolt-head seating surfaces. The bolthead<br />

seating surface is machined so it<br />

describes a radius on the inboard-side <strong>of</strong><br />

the bolt head as viewed from the top <strong>of</strong><br />

..<br />

the bolt head similar to the <strong>429</strong>CJlSCJ<br />

pictured below. This reduces stress concentration<br />

on the rod at the bolt heads.<br />

35 1M/<strong>400</strong>-The 3 5 1 MI<strong>400</strong> engines use<br />

the same connecting rods regardless <strong>of</strong><br />

the engine or year. They have a 6.580-inch<br />

center-to-center length, small-end diameter<br />

<strong>of</strong> 0.9738 inch, big-end diameter <strong>of</strong><br />

2.4356 inches and the rod is spot-faced at<br />

the bolt-head seating surfaces.<br />

<strong>429</strong>1460-Although there is more than<br />

one <strong>429</strong>1460 connecting rod, their vital<br />

statistics are identical. They are forgedsteel,<br />

have a 6.605-inch center-to-center<br />

length, 1.309-inch small-end diameter and<br />

2.6529-inch diameter at the big end.<br />

What distinguishes the different <strong>429</strong>1460<br />

connecting-rod assemblies is the machining<br />

<strong>of</strong> the basic connecting-rod forging<br />

and the rod-bolt design. Although there<br />

are two connecting-rod forgings, C8VE-A<br />

and DOOE-A, the type <strong>of</strong> machining and<br />

the rod-bolt design are the major things<br />

to be aware <strong>of</strong>.<br />

All early <strong>429</strong>1460 connecting-rod bolthead<br />

seats were broached. Rectangularhead<br />

bolts were installed in these assemblies.<br />

<strong>To</strong> increase the fatigue strength <strong>of</strong><br />

the rectangular bolt head, the bolt-headto-shank<br />

radius was increased in 1972.<br />

This change didn't make the bolt or rod<br />

suitable for heavy-duty or high-performance<br />

use. Consequently, a new connecting<br />

rod with spot-faced bolt-head<br />

seats and bolts with "football" heads<br />

were used. These rods were installed in<br />

<strong>429</strong> CJ and SCJ, 460 truck and <strong>429</strong> and<br />

460 Police engines. Use <strong>of</strong> the broachedrod<br />

was continued in standard <strong>429</strong>1460<br />

engines.<br />

With all this connecting-rod information<br />

in mind, consider these choices. If<br />

your engine is for everyday passenger-car<br />

use, the broached rod with rectangularhead<br />

bolts is adequate. <strong>How</strong>ever, if you<br />

are preparing your engine for heavy-duty<br />

use, take advantage <strong>of</strong> one item that will<br />

interchange between the 335- and 385-<br />

Series <strong>Ford</strong>s-the rod bolts. Use the high-<br />

strength <strong>351C</strong> Boss/HO bolts in your<br />

spot-faced rods. If you're going to use<br />

broached rods, upgrade them with 35 1C<br />

BosslHO bolts. They won't be as strong<br />

as the spot-faced rod assemblies, however<br />

they will be much stronger than before.<br />

PISTONS<br />

As with most 335 and 385 engine components,<br />

the pistons are similar, but different<br />

in one or more respects-piston<br />

diameter, wrist-pin diameter or compression<br />

height. They appear similar because<br />

most have two intake-valve reliefs. <strong>How</strong>ever,<br />

the differences become apparent<br />

when it comes to interchangeability.<br />

<strong>351C</strong>-2V, -4V, and CJ-These cast-aluminum<br />

pistons are the same, consequently<br />

they are fully interchangeable between<br />

2V, 4V and CJ engines. Their flat tops are<br />

only disturbed by two intake-valve reliefs.<br />

35 1C Boss and HO-Boss and HO versions<br />

<strong>of</strong> the <strong>351C</strong> pistons are quite different<br />

from the standard piston design. They are<br />

I<br />

I<br />

Standard <strong>429</strong>/460 connecting rod on left and <strong>429</strong> SCJ and CJ rod on right. Only<br />

difference between them is machining at their bolt-head surfaces- broached versus spotfaced.