How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

-<br />

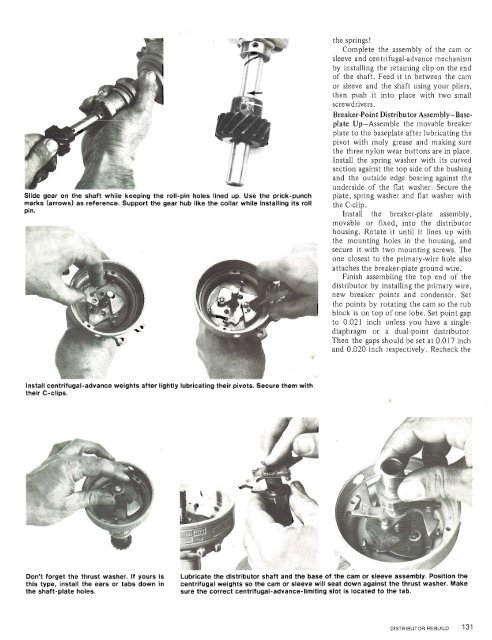

Slide gear on the shaft while keeping the roll-pin holes lined up. Use the prick-punch<br />

marks (arrows) as reference. Support the gear hub like the collar while installing its roll<br />

pin.<br />

. I.<br />

. ,<br />

4<br />

sleeve and centrifugal-advance mechanism<br />

by installing the retaining clip on the end<br />

<strong>of</strong> the shaft. Feed it in between the cam<br />

or sleeve and the shaft using your pliers,<br />

then push it into place with two small<br />

screwdrivers.<br />

Breaker-Point Distributor Assembly-Baseplate<br />

Up-Assemble the movable breaker<br />

plate to the baseplate after lubricating the<br />

pivot with moly grease and making sure<br />

the three nylon wear buttons are in place.<br />

lnstall the spring washer with its curved<br />

section against the top side <strong>of</strong> the bushing<br />

and the outside edge bearing against the<br />

underside <strong>of</strong> the flat washer. Secure the<br />

plate, spring washer and flat washer with<br />

the C-clip.<br />

Install the breaker-plate assembly,<br />

movable or fixed, into the distributor<br />

housing. Rotate it until it lines up with<br />

the mounting holes in the housing, and<br />

secure it with two mounting screws. The<br />

one closest to the primary-wire hole also<br />

attaches the breaker-plate ground wire.<br />

Finish assembling the top end <strong>of</strong> the<br />

distributor by installing the primary wire,<br />

new breaker points and condensor. Set<br />

the points by rotating the cam so the rub<br />

bloik is on top <strong>of</strong> on; lobe. Set point gap<br />

to 0.021 inch unless you have a single-<br />

7 t.' diaphragm or a dual-point distributor.<br />

Then the gaps should be set at 0.017 inch<br />

and 0.020 inch respectively. Recheck the<br />

.<br />

Install centrifugal-advance weights after lightly lubricating their pivots. Secure them with<br />

their C-clips.<br />

Don't forget the thrust washer. If yours is<br />

this type, install the ears or tabs down in<br />

the shaft-plate holes.<br />

Lubricate the distributor shaft and the base <strong>of</strong> the cam or sleeve assembly. Position the<br />

centrifugal weights so the cam or sleeve will seat down against the thrust washer. Make<br />

sure the correct centrifugal-advance-limiting slot is located to the tab.