How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

--<br />

Boring leaves a sharp edge at the top <strong>of</strong> each bore. Chamfer bores with a file to provide a<br />

lead-in for installing the rings and pistons. This can be done after honing, however doing it<br />

first eliminates danger <strong>of</strong> damaging finished bore with file end.<br />

Chrome is very tough and lasts longer<br />

than moly under these conditions. <strong>How</strong>ever,<br />

unless you have this situation, use<br />

moly rings. Their life will be much better<br />

than the chrome type, and they require<br />

virtually zero break-in mileage. As for<br />

plain cast-iron rings, they break in<br />

quicker than chrome-faced cast-iron rings,<br />

but they also wear out quicker. I recommend<br />

you don't consider them.<br />

What's the Difference-The advantage <strong>of</strong><br />

a moly ring over a plain or chrome one is<br />

the moly-type carries more <strong>of</strong> its own<br />

oil. It has surface voids-little depressionswhich<br />

contain oil much in the same manner<br />

as the cross-hatching <strong>of</strong> a honed<br />

cylinder. Plain and chrome rings have<br />

virtually no voids and must depend<br />

almost totally on cylinder-wall crosshatch<br />

to supply lubricating oil. When the<br />

piston travels down during the power<br />

stroke, the cylinder wall is exposed to<br />

the burning fuel. Consequently, the oil<br />

on the wall is partially burned away,<br />

meaning the piston rings will not receive<br />

full lubrication during the return trip up<br />

the bore on the exhaust stroke. The molytype<br />

ring carries its own lubrication<br />

which is not directly exposed to combustion.<br />

The reason for different bore finishes<br />

according to the type ring used should<br />

now be obvious. A chrome ring depends<br />

on a coarsely finished cylinder wall<br />

to retain lubricating oil. If plain or<br />

chrome rings are used, the bore should<br />

be finish-honed with a 280-grit stone.<br />

A <strong>400</strong>-grit stone is used for moly rings.<br />

A 30" cross-hatch pattern is used for<br />

all ring types.<br />

Install the Main-Bearing Caps-Prior to<br />

delivering your block for boring and/or<br />

honing, install the main-bearing caps.<br />

<strong>To</strong>rque them to specification: 95-105<br />

ft. lbs. for all 1/2-13 main-bearing bolts.<br />

For those using four-bolt mains, the outer<br />

bolts <strong>of</strong> the <strong>351C</strong> CJ and Boss 351 are<br />

torqued 35-40 ft. lbs. and the <strong>429</strong>CJ<br />

and Super CJ are torqued 70-80 ft. lbs.<br />

This is necessary because the load imposed<br />

on the block by the main-bearing<br />

bolts distorts the bores slightly. Therefore,<br />

the bores are not the same shape before<br />

and after the main cap bolts are torqued.<br />

Consequently, the object <strong>of</strong> boring and<br />

honing the block with the main caps<br />

torqued to spec ensures that the bores<br />

will be as close to perfect by simulating<br />

the normal operating stresses and deflections<br />

in the block during the machining<br />

processes.<br />

Cylinder heads are another source <strong>of</strong><br />

bore distortion, but how can you hone<br />

the engine with the heads in place<br />

Fear not, the dilemma has been solved.<br />

Some engine shops use a torque plate<br />

when boring and honing. The 2-inchthick<br />

steel torque plate has four largediameter<br />

holes centered on the engine<br />

bores to allow clearance for boring and<br />

honing. The plate is torqued to the<br />

block just like the heads. If the shop you<br />

choose does not use a torque plate,<br />

don't be overly concerned. This is not<br />

absolutely essential unless you are building<br />

an engine for all-out racing. Using<br />

a torque plate increases the machining<br />

costs due to the additional time required.<br />

Therefore, if you are on a tight budget,<br />

make some cost comparisons. Regardless<br />

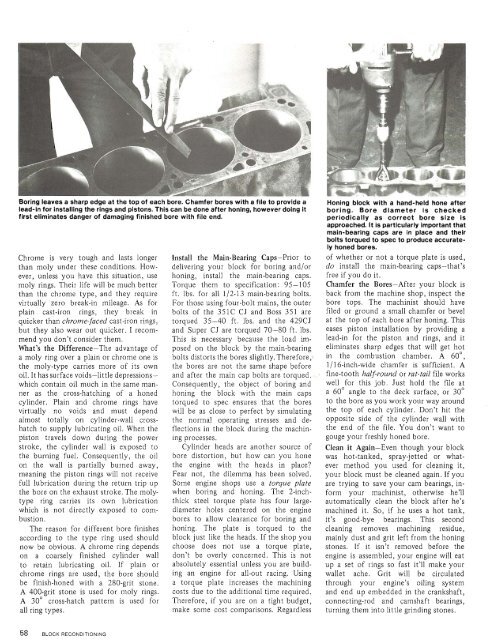

Honing block with a hand-held hone after<br />

boring. Bore diameter is checked<br />

periodically as correct bore size is<br />

approached. It is particularly important that<br />

main-bearing caps are in place and their<br />

bolts torqued to spec to produce accurately<br />

honed bores.<br />

<strong>of</strong> whether or not a torque plate is used,<br />

do install the main-bearing caps-that's<br />

free if you do it.<br />

Chamfer the Bores-After your block is<br />

back from the machine shop, inspect the<br />

bore tom. The machinist should have<br />

filed or ground a small chamfer or bevel<br />

at the top <strong>of</strong> each bore after honing. This<br />

eases piston installation by providing a<br />

lead-in for the piston and rings, and it<br />

eliminates sharp edges that will get hot<br />

in the combustion chamber. A 60°,<br />

1116-inch-wide chamfer is sufficient. A<br />

fine-tooth halfround or rat-tail file works<br />

well for this job. Just hold the file at<br />

a 60" angle to the deck surface, or 30"<br />

to the bore as you work your way around<br />

the top <strong>of</strong> each cylinder. Don't hit the<br />

opposite side <strong>of</strong> the cylinder wall with<br />

the end <strong>of</strong> the file. You don't want to<br />

gouge your freshly honed bore.<br />

Clean it Again-Even though your block<br />

was hot-tanked, spray-jetted or whatever<br />

method you used for cleaning it,<br />

your block must be cleaned again. If you<br />

are trying to save your cam bearings, inform<br />

your machinist, otherwise he'U<br />

automatically clean the block after he's<br />

machined it. So, if he uses a hot tank,<br />

it's good-bye bearings. This second<br />

cleaning removes machining residue,<br />

mainly dust and grit left from the honing<br />

stones. If it isn't removed before the<br />

engine is assembled, your engine will eat<br />

up a set <strong>of</strong> rings so fast it'll make your<br />

wallet ache. Grit will be circulated<br />

through your engine's oiling system<br />

and end up embedded in the crankshaft,<br />

connecting-rod and camshaft bearings,<br />

turning them into little grinding stones.