How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

cam sprocket and chain, and then the<br />

crankshaft sprocket.<br />

After you have the chain and sprockets<br />

<strong>of</strong>f, check the nylon teeth for cracks or<br />

breakage. If there are any, replace that<br />

sprocket. Also, treat it like a chain. Replace<br />

the cam sprocket if it has more than<br />

50,000 miles on it regardless <strong>of</strong> its visual<br />

condition. This is particularly true if you<br />

live in a hot climate and your engine is a<br />

'73 or later emission-controlled model<br />

whch operates at higher temperatures. In<br />

this case, I suggest replacing your aluminumlnylon<br />

cam sprocket with the castiron<br />

type.<br />

As for the cast-iron type sprocket,<br />

they won't be cracked, but the plates<br />

which make up a silent chain may have<br />

worn ridges in the sprocket teeth so one<br />

or both <strong>of</strong> the sprockets should be replaced.<br />

<strong>To</strong> judge tooth wear is difficult.<br />

Drag your fingernail across the face <strong>of</strong> a<br />

tooth. It if is rough to the point <strong>of</strong> making<br />

your fingernail hang up or jump from<br />

ridge to ridge, replace the sprocket/s.<br />

REMOVE CRANK, RODS & PISTONS<br />

BEFORE THE CAM<br />

A camshaft can be removed before<br />

the crankshaft and rod-and-piston assemblies<br />

are out, but it's more convenient to<br />

reverse the procedure. With the crank and<br />

rods out <strong>of</strong> the way, you'll have access to<br />

the full length <strong>of</strong> the cam from inside the<br />

block rather than just the end <strong>of</strong> it from<br />

the front <strong>of</strong> the block.<br />

Remove the Ridge-Because the top piston<br />

ring doesn't travel all the way to the<br />

top <strong>of</strong> its bore when its piston is at TDC,<br />

there is approximately 114 inch <strong>of</strong> unworn<br />

bore and carbon buildup at the top<br />

<strong>of</strong> the cylinder called a ridge. It should be<br />

removed before you attempt to remove<br />

the rod and piston assemblies, particularly<br />

if your pistons can be saved. They can be<br />

damaged easily if forced out over the<br />

ridge. If you know you aren't going to<br />

be using your old pistons, they can be<br />

driven out the top <strong>of</strong> their bores using a<br />

long punch or bar which reaches up under<br />

the dome <strong>of</strong> each piston. Don't hammer<br />

on the rods.<br />

<strong>To</strong> remove the ridges, you'll have to<br />

use a tool appropriately called a ridge<br />

reamer. This tool has a cutter mounted<br />

in a fixture which can be adjusted to fit<br />

the bore. A socket and handle or wrench<br />

from your tool box is all you need to<br />

rotate the tool to do the cutting, or<br />

reaming.<br />

As you go from bore to bore, youll<br />

need to rotate the crankshaft periodically<br />

to move the pistons down their bores so<br />

you'll have clearance for the ridge reamer.<br />

Fate <strong>of</strong> most high-mileage aluminum/nylon<br />

cam sprockets: cracked and broken teeth.<br />

Hot climates and emission controls cause<br />

an engine to operate at higher temperatures<br />

and aggravate the problem.<br />

When cutting a ridge, cut the ridge orzly<br />

to match the worn bore. This is all that's<br />

required to remove a piston. Remove any<br />

more material and you may have to<br />

4'<br />

rebore your engine-whether it needed it<br />

or not.<br />

Now you can get on with the rod-andpiston<br />

removal process. Roll the engine<br />

over on its back to expose the bottom<br />

end. Before removing any corznectingrod<br />

caps, make certain each rod and cap<br />

is numbered to match its respective cylinder.<br />

This for locating the rod-andpiston<br />

assembly in the correct bore and<br />

to assemble the rod correctly to its piston.<br />

Numbers should be on the small machined<br />

flat next to the junction <strong>of</strong><br />

each rod and cap. Also, the numbers<br />

should be on the right side <strong>of</strong> the rods<br />

and caps that are for the right cylinder<br />

bank, and on the left side for those in the<br />

left bank. This check is a precautionary<br />

step because <strong>Ford</strong> stamps the numbers on<br />

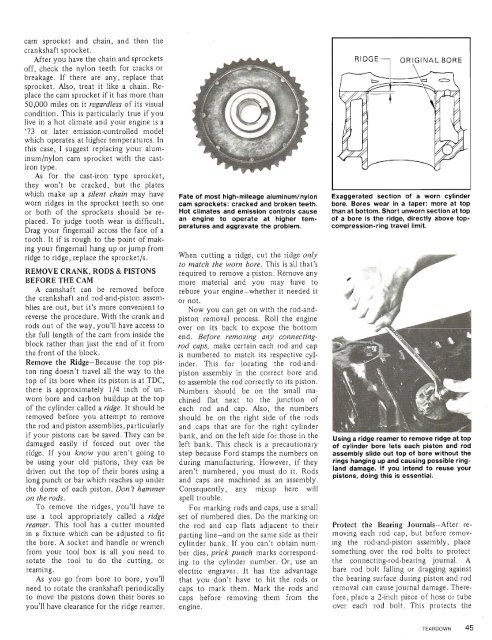

Exaggerated section <strong>of</strong> a worn cylinder<br />

bore. Bores wear in a taper: more at top<br />

than at bottom. Short unworn section at top<br />

<strong>of</strong> a bore is the ridge, directly above topcompression-ring<br />

':<br />

travel limit.<br />

fl<br />

I'<br />

Using a ridge reamer to remove ridge at top<br />

<strong>of</strong> cylinder bore lets each piston and rod<br />

assembly slide out top <strong>of</strong> bore without the<br />

du;ing manufacturing. o ow ever, if they rings hanging up and causing possible ringaren't<br />

you must do it. ~~d~ land damage. If you intend to reuse your<br />

pistons, doing this is essential.<br />

and caps are machined as an assembly.<br />

consequently, any mixup here will<br />

spell trouble.<br />

For marking rods and caps, use a small<br />

set <strong>of</strong> numbered dies. Do the marking on<br />

the rod and cap flats adjacent to their<br />

parting line-and on the same side as their<br />

cylinder bank. If you can't obtain number<br />

dies, prick punch marks corresponding<br />

to the cylinder number. Or, use an<br />

electric engraver. It has the advantage<br />

that you don't have to hit the rods or<br />

caps to mark them. Mark the rods and<br />

caps before removing them from the<br />

engine.<br />

Protect the Bearing Journals-After removing<br />

each rod cap, but before removing<br />

the rod-and-piston assembly, place<br />

something over the rod bolts to protect<br />

the connecting-rod-bearing journal. A<br />

bare rod bolt falling or dragging against<br />

the bearing surface during piston and rod<br />

removal can cause journal damage. Therefore,<br />

place a 2-inch piece <strong>of</strong> hose or tube<br />

over each rod bolt. This protects the<br />

I<br />

TEARDOWN 45