How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

or 68 lbs. in this case. If a spring does not<br />

exceed or at least meet the minimum, it<br />

should be replaced. If your engine will be<br />

operated at its upper RPM limit, or is one<br />

<strong>of</strong> the high-performance models, you<br />

should make sure valve-spring load at<br />

least meets the minimum standard limit.<br />

Load at Open Height-Another commonly<br />

listed specification is a spring's compressed<br />

load when its valve is fully open. A typical<br />

specification is 240-266 lbs. at 1.330<br />

inches. Just as with the installed-height<br />

load, a spring must fall within the 10%<br />

minimum-load limit or be replaced. In<br />

this case, the minimum is 216 lbs. Again,<br />

consider how your engine will be operated<br />

when checking the springs.<br />

Solid Height-Solid height describes the<br />

height <strong>of</strong> a coil spring when it is totally<br />

compressed to the point where each coil<br />

touches the adjacent coil. The spring is<br />

said to coil bind, or go solid. Coil springs<br />

should never be compresed to this height<br />

in normal service. If a valve spring were to<br />

reach its solid height before its valve is<br />

fully opened, the load on the valve train<br />

would theoretically approach infinity.<br />

But before this could happen, the weakest<br />

component in the valve train will failsomething<br />

bends or breaks-usually a<br />

pushrod.<br />

Squareness-Valve-spring squareness is<br />

how straight a spring stands on a flat surface,<br />

or how much it tilts. It is desirable<br />

for a spring to be square so it loads the<br />

spring retainer evenly around its full circumference.<br />

Uneven retainer loading increases<br />

stem and guide wear-something<br />

you should minimize. Limit out-<strong>of</strong>-squareness<br />

to 1/16 inch measured from the top<br />

<strong>of</strong> the spring to a vertical surface with<br />

the spring sitting on a horizontal surface.<br />

CHECK YOUR VALVE SPRINGS<br />

Of the spring characteristics just<br />

covered, the ones which should be checked<br />

are squareness, and the installed and open<br />

spring loads, plus making sure the spring<br />

doesn't reach its solid position in the fullopen<br />

position. A flat surface, square and<br />

something to measure with are all that's<br />

required to check for squareness. When<br />

you're all set up, rotate the spring you're<br />

checking against the square to determine<br />

its maximum tilt, then measure it. If the<br />

gap at the top <strong>of</strong> the spring exceeds 1 /I 6<br />

inch, replace it.<br />

As for the last two checks, a valvespring<br />

tester is required. Two types <strong>of</strong><br />

testers are normally used, but both do the<br />

same thing. They permit manual compression<br />

<strong>of</strong> a spring to the opened and installed<br />

heights so the spring's loads at<br />

these heights can be read. The question is,<br />

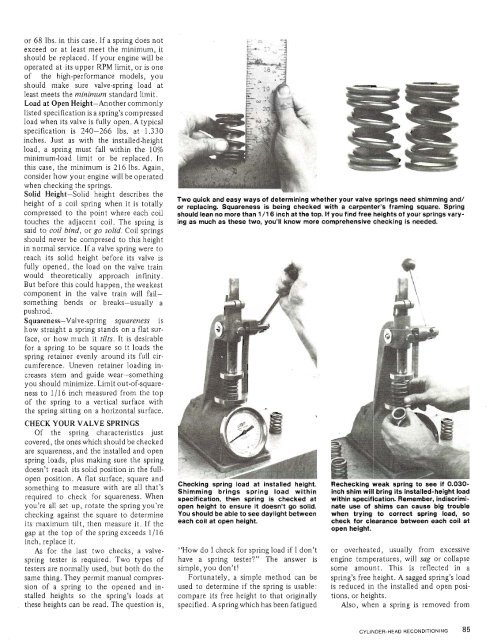

Two quick and easy ways <strong>of</strong> determining whether your valve springs need shimming and/<br />

or replacing. Squareness is being checked with a carpenter's framing square. Spring<br />

should lean no more than 1 /16 inch at the top. If you find free heights <strong>of</strong> your springs varying<br />

as much as these two, you'll know more comprehensive checking is needed.<br />

Checking spring load at installed height. Rechecking weak spring to see if 0.030-<br />

Shimming brings spring load within inch shim will bring its installed-height load<br />

specification, then spring-is checked at withln specification. Remember, indiscrimiopen<br />

height to ensure it doesn't go solid. nate use <strong>of</strong> shims can cause big trouble<br />

You should be able to see daylight between when trying to correct spring load, so<br />

each coil at open height.<br />

check for clearance between each coil at<br />

open height.<br />

"<strong>How</strong> do I check for spring load if I don't<br />

have a spring tester" The answer is<br />

simple, you don't!<br />

Fortunately, a simple method can be<br />

used to determine if the spring is usable:<br />

compare its free height to that originally<br />

specified. A spring which has been fatigued<br />

or overheated, usually from excessive<br />

engine temperatures, will sag or collapse<br />

some amount. This is reflected in a<br />

spring's free height. A sagged spring's load<br />

is reduced in the installed and open positions,<br />

or heights.<br />

Also, when a spring is removed from