How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1<br />

Oil rings are easy, but tricky to install. After<br />

the expander-spacer, top rail goes on next.<br />

Now's the time for checking the expanderspacer<br />

ends. They shouldn't overlap. If<br />

they the rail9 'Orrect the<br />

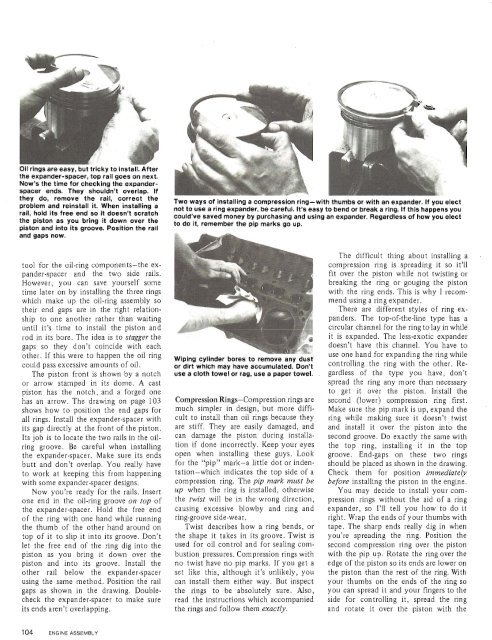

Two ways <strong>of</strong> installing a compression ring-with thumbs or with an expander. If you elect<br />

problem and reinstall When installing a<br />

not to use a ring expander, be careful. It's easy to bend or break a ring. If this happens you<br />

its free end it scratch could've saved money by purchasing and using an expander. Regardless <strong>of</strong> how you elect<br />

the piston as YOU bring it down over the<br />

to do it, remember the pip marks go up,<br />

piston and into its groove. - Position the rail<br />

and gaps now.<br />

tool for the oil-ring components-the expander-spacer<br />

and the two side rails.<br />

<strong>How</strong>ever, you can save yourself some<br />

time later on by installing the three rings<br />

which make up the oil-ring assembly so<br />

their end gaps are in the right relationship<br />

to one another rather than waiting<br />

until it's time to install the piston and<br />

rod in its bore. The idea is to stagger the<br />

gaps so they don't coincide with each<br />

other. If this were to happen the oil ring<br />

could pass excessive amounts <strong>of</strong> oil.<br />

The piston front is shown by a notch<br />

or arrow stamped in its dome. A cast<br />

piston has the notch, and a forged one<br />

has an arrow. The drawing on page 103<br />

shows how to position the end gaps for<br />

all rings. Install the expander-spacer with<br />

its gap directly at the front <strong>of</strong> the piston.<br />

Its job is to locate the two rails in the oilring<br />

groove. Be careful when installing<br />

the expander-spacer. Make sure its ends<br />

butt and don't overlap. You really have<br />

to work at keeping this from happening<br />

with some expander-spacer designs.<br />

Now you're ready for the rails. Insert<br />

one end in the oil-ring groove on top <strong>of</strong><br />

the expander-spacer. Hold the free end<br />

<strong>of</strong> the ring with one hand while running<br />

the thumb <strong>of</strong> the other hand around on<br />

top <strong>of</strong> it to slip it into its groove. Don't<br />

let the free end <strong>of</strong> the ring dig into the<br />

piston as you bring it down over the<br />

piston and into its groove. Install the<br />

other rail below the expander-spacer<br />

using the same method. Position the rail<br />

gaps as shown in the drawing. Doublecheck<br />

the expander-spacer to make sure<br />

its ends aren't overlapping.<br />

Wlplng cylinder bores to remove any dust<br />

or dirt which may have accumulated. Don't<br />

use a cloth towel or rag, use a paper towel.<br />

Compression Rings-Compression rings are<br />

much simpler in design, but more difficult<br />

to install than oil rings because they<br />

are stiff. They are easily damaged, and<br />

can damage the piston during installation<br />

if done incorrectly. Keep your eyes<br />

open when installing these guys. Look<br />

for the "pip" mark-a little dot or indentation-which<br />

indicates the top side <strong>of</strong> a<br />

compression ring. The pip mark must be<br />

up when the ring is installed, otherwise<br />

the twist will be in the wrong direction,<br />

causing excessive blowby and ring and<br />

ring-groove side-wear.<br />

Twist describes how a ring bends, or<br />

the shape it takes in its groove. Twist is<br />

used for oil control and for sealing combustion<br />

pressures. Compression rings with<br />

no twist have no pip marks. If you get a<br />

set like this, although it's unlikely, you<br />

can install them either way. But inspect<br />

the rings to be absolutely sure. Also,<br />

read the instructions which accompanied<br />

the rings and follow them exactly.<br />

The difficult thing about installing a<br />

compression ring is spreading it so it'll<br />

fit over the piston while not twisting or<br />

breaking the ring or gouging the piston<br />

with the ring ends. This is why I recommend<br />

using a ring expander.<br />

There are different styles <strong>of</strong> ring expanders.<br />

The top-<strong>of</strong>-the-line type has a<br />

circular channel for the ring to lay in while<br />

it is expanded. The less-exotic expander<br />

doesn't have this channel. You have to<br />

use one hand for expanding the ring while<br />

controlling the ring with the other, Regardless<br />

<strong>of</strong> the type you have, don't<br />

spread the ring any more than necessary<br />

to get it over the piston. Install the<br />

second (lower) omp press ion ring first.<br />

Make sure the pip mark is up, expand the<br />

ring while making sure it doesn't twist<br />

and install it over the piston into the<br />

second groove. Do exactly the same with<br />

the top ring, installing it in the top<br />

groove. End-gaps on these two rings<br />

should be placed as shown in the drawing.<br />

Check them for position immediately<br />

before installing the piston in the engine.<br />

You may decide to install your compression<br />

rings without the aid <strong>of</strong> a ring<br />

expander, so I'll tell you how to do it<br />

right. Wrap the ends <strong>of</strong> your thumbs with<br />

tape. The sharp ends really dig in when<br />

you're spreading the ring. Position the<br />

second compression ring over the piston<br />

with the pip up. Rotate the ring over the<br />

edge <strong>of</strong> the piston so its ends are lower on<br />

the piston than the rest <strong>of</strong> the ring. With<br />

your thumbs on the ends <strong>of</strong> the ring so<br />

you can spread it and your fingers to the<br />

side for controlling it, spread the ring<br />

and rotate it over the piston with the