How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

10 DIAGNOSIS<br />

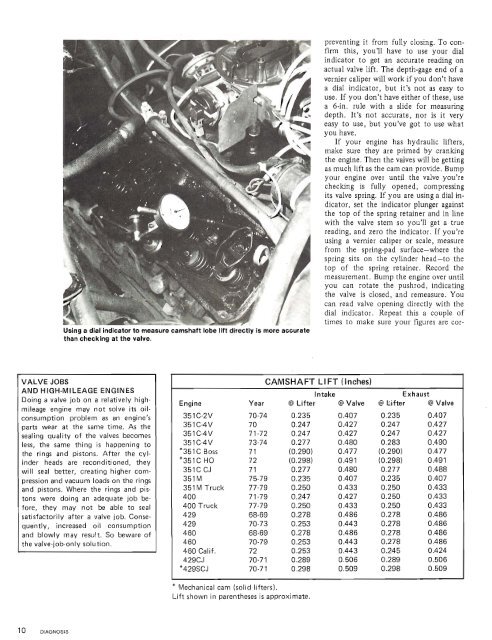

Using a dial indlcator to measure camshaft lobe lift dlrectly is more accurate<br />

than checklng at the valve.<br />

preventing it from fully closing. <strong>To</strong> confirm<br />

this, you'll have to use your dial<br />

indicator to get an accurate reading on<br />

actual valve lift. The depth-gage end <strong>of</strong> a<br />

vernier caliper will work if you don't have<br />

a dial indicator, but it's not as easy to<br />

use. If you don't have either <strong>of</strong> these, use<br />

a 6-in. rule with a slide for measuring<br />

depth. It's not accurate, nor is it very<br />

easy to use, but you've got to use what<br />

you have.<br />

If your engine has hydraulic lifters,<br />

make sure they are primed by cranking<br />

the engine. Then the valves will be getting<br />

as much lift as the cam can provide. Bump<br />

your engine over until the valve you're<br />

checking is fully opened, compressing<br />

its valve spring. If you are using a dial indicator,<br />

set the indicator plunger against<br />

the top <strong>of</strong> the spring retainer and in line<br />

with the valve stem so you'll get a true<br />

reading, and zero the indicator. If you're<br />

using a vernier caliper or scale, measure<br />

from the spring-pad surface-where the<br />

spring sits on the cylinder head-to the<br />

top <strong>of</strong> the spring retainer. Record the<br />

measurement. Bump the engine over until<br />

you can rotate the pushrod, indicating<br />

the valve is closed, and remeasure. You<br />

can read valve opening directly with the<br />

dial indicator. Repeat this a couple <strong>of</strong><br />

times to make sure your figures - are cor-<br />

VALVE JOBS<br />

AND HIGH-MILEAGE ENGINES<br />

Doing a valve job on a relatively highmileage<br />

engine may not solve its oilconsumption<br />

problem as an engine's<br />

parts wear at the same time. As the<br />

sealing quality <strong>of</strong> the valves becomes<br />

less, the same thing is happening to<br />

the rings and pistons. After the cylinder<br />

heads are reconditioned, they<br />

will seal better, creating higher compression<br />

and vacuum loads on the rings<br />

and pistons. Where the rings and pistons<br />

were doing an adequate job before,<br />

they may not be able to seal<br />

satisfactorily after a valve job. Consequently,<br />

increased oil consumption<br />

and blowly may result. So beware <strong>of</strong><br />

the valve-job-only solution.<br />

CAMSHAFT LIFT [Inches)<br />

Intake<br />

Exhaust<br />

Engine Year @ Lifter @ Valve c@ Lifter @ Valve<br />

351 C-2V 70-74 0.235 0.407 0.235 0.407<br />

351 C-4V 70 0.247 0.427 0.247 0.427<br />

<strong>351C</strong>-4V 71-72 0.247 0.427 0.247 0.427<br />

351 C-4V 73-74 0.277 0.480 0.283 0.490<br />

"351 C Boss 71 (0.290) 0.477 (0.290) 0.477<br />

"351 C HO 72 (0.298) 0.491 (0.298) 0.491<br />

<strong>351C</strong> CJ 71 0.277 0.480 0.277 0.488<br />

351 M 75-79 0.235 0.407 0.235 0.407<br />

351 M Truck 77-79 0.250 0.433 0.250 0.433<br />

<strong>400</strong> 71-79 0.247 0.427 0.250 0.433<br />

<strong>400</strong> Truck 77-79 0.250 0.433 0.250 0.433<br />

<strong>429</strong> 68-69 0.278 0.486 0.278 0.486<br />

<strong>429</strong> 70-73 0.253 0.443 0.278 0.486<br />

460 68-69 0.278 0.486 0.278 0.486<br />

460 70-79 0.253 0.443 0.278 0.486<br />

460 Calif. 72 0.253 0.443 0.245 0.424<br />

<strong>429</strong>CJ 70-71 0.289 0.506 0.289 0.506<br />

"<strong>429</strong>SCJ 70-71 0.298 0.509 0.298 0.509<br />

* Mechanical cam (solid lifters).<br />

Lift shown in parentheses is approximate.