How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

If you are installing a new or reground<br />

camshaft, remove drive pin from old<br />

camshaft before turning it in as a core.<br />

Replacement cams usually don't Include<br />

the pin. Remove yours by clamping on it<br />

with Vise-Grips and working it out.<br />

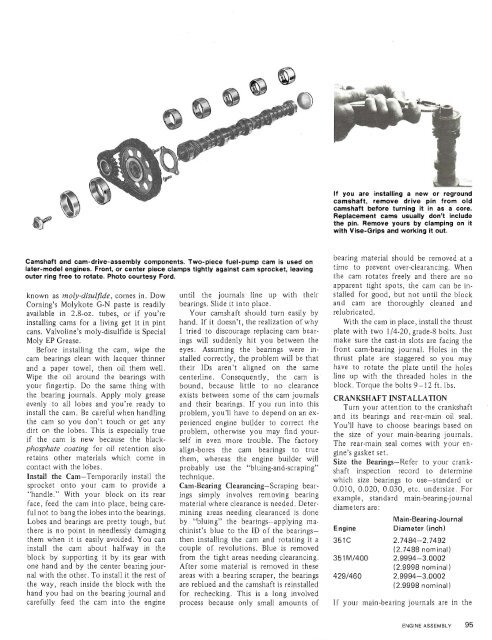

Camshaft and cam-drive-assembly components. Two-piece fuel-pump cam is used on<br />

later-model engines. Front, or center piece clamps tightly against cam sprocket, leaving<br />

outer ring free to rotate. Photo courtesy <strong>Ford</strong>.<br />

known as moly-disulfide, comes in. Dow<br />

Corning's Molykote G-N paste is readily<br />

available in 2.8-oz. tubes, or if you're<br />

installing cams for a living get it in pint<br />

cans. Valvoline's moly-disulfide is Special<br />

Moly EP Grease.<br />

Before installing the cam, wipe the<br />

cam bearings clean with lacquer thinner<br />

and a paper towel, then oil them well.<br />

Wipe the oil around the bearings with<br />

your fingertip. Do the same thing with<br />

the bearing journals. Apply moly grease<br />

evenly to all lobes and you're ready to<br />

install the cam. Be careful when handling<br />

the cam so you don't touch or get any<br />

dirt on the lobes. This is especially true<br />

if the cam is new because the blackphosphate<br />

coating for oil retention also<br />

retains other materials which come in<br />

contact with the lobes.<br />

Install the Cam-Temporarily install the<br />

sprocket onto your cam to provide a<br />

"handle." With your block on its rear<br />

face, feed the cam into place, being careful<br />

not to bang the lobes into the bearings.<br />

Lobes and bearings are pretty tough, but<br />

there is no point in needlessly damaging<br />

them when it is easily avoided. You can<br />

install the cam about halfway in the<br />

block by supporting it by its gear with<br />

one hand and by the center bearing journal<br />

with the other. <strong>To</strong> install it the rest <strong>of</strong><br />

the way, reach inside the block with the<br />

hand you had on the bearing journal and<br />

carefully feed the cam into the engine<br />

until the journals line up with their<br />

bearings. Slide it into place.<br />

<strong>Your</strong> camshaft should turn easily by<br />

hand. If it doesn't, the realization <strong>of</strong> why<br />

I tried to discourage replacing cam bearings<br />

will suddenly hit you between the<br />

eyes. Assuming the bearings were installed<br />

correctly, the problem will be that<br />

their IDS aren't aligned on the same<br />

centerline. Consequently, the cam is<br />

bound, because little to no clearance<br />

exists between some <strong>of</strong> the cam journals<br />

and their bearings. If you run into this<br />

problem, you'll have to depend on an experienced<br />

engine builder to correct the<br />

problem, otherwise you may find yourself<br />

in even more trouble. The factory<br />

align-bores the cam bearings to true<br />

them, whereas the engine builder will<br />

probably use the "bluing-and-scraping"<br />

technique.<br />

Cam-Bearing Clearancing-Scraping bearings<br />

simply involves removing bearing<br />

material where clearance is needed. Determining<br />

areas needing clearanced is done<br />

by "bluing" the bearings-applying machinist's<br />

blue to the ID <strong>of</strong> the bearingsthen<br />

installing the cam and rotating it a<br />

couple <strong>of</strong> revolutions. Blue is removed<br />

from the tight areas needing clearancing.<br />

After some material is removed in these<br />

areas with a bearing scraper, the bearings<br />

are reblued and the camshaft is reinstalled<br />

for rechecking. This is a long involved<br />

process because only small amounts <strong>of</strong><br />

bearing material should be removed at a<br />

time to prevent over-clearancing. When<br />

the cam rotates freely and there are no<br />

apparent tight spots, the cam can be installed<br />

for good, but not until the block<br />

and cam are thoroughly cleaned and<br />

relubricated.<br />

With the cam in place, install the thrust<br />

plate with two 1/4-20, grade-8 bolts. Just<br />

make sure the cast-in slots are facing the<br />

front cam-bearing journal. Holes in the<br />

thrust plate are staggered so you may<br />

have to rotate the plate until the holes<br />

line up with the threaded holes in the<br />

block. <strong>To</strong>rque the bolts 9-12 ft. lbs.<br />

CRANKSHAFT INSTALLATION<br />

Turn your attention to the crankshaft<br />

and its bearings and rear-main oil seal.<br />

You'll have to choose bearings based on<br />

the size <strong>of</strong> your main-bearing journals.<br />

The rear-main seal comes with your engine's<br />

gasket set.<br />

Size the Bearings-Refer to your crankshaft<br />

inspection record to determine<br />

which size bearings to use-standard or<br />

0.010, 0.020, 0.030, etc. undersize. For<br />

example, standard main-bearing-journal<br />

diameters are:<br />

Main-Bearing-Journal<br />

Engine<br />

Diameter (inch)<br />

2.7484-2.7492<br />

(2.7488 nominal)<br />

2.9994-3.0002<br />

(2.9998 nominal)<br />

2.9994-3.0002<br />

(2.9998 nominal)<br />

If your main-bearing journals are in the<br />

ENGINE ASSEMBLY 95