How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

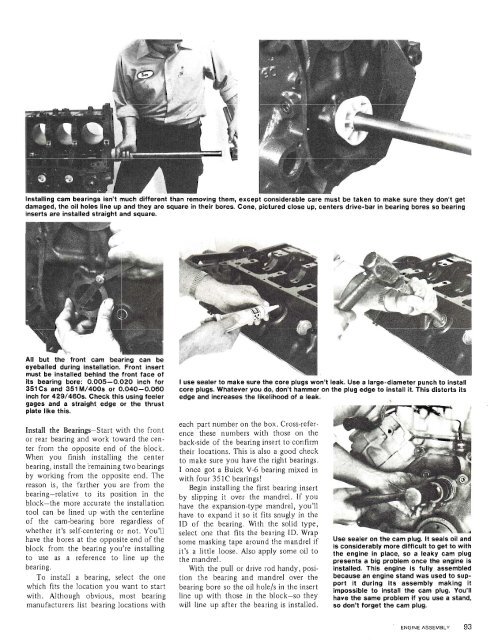

.,., ....., ,. ,., .,. . .,. different than removing them, except c ~_ ._ lust be taken to make sure they don't get<br />

damaged, the oil holes line up and they are square in their bores. Cone, pictured close up, centers drive-bar in bearing bores so bearing<br />

inserts are installed straight and square.<br />

eyeballed during installation. Front insert<br />

must be installed behind the front face <strong>of</strong><br />

its bearing bore: 0.005-0.020 inch for I use sealer to make sure the core plugs won't leak. Use a large-diameter punch to install<br />

351 Cs and 351 M/<strong>400</strong>s or 0.040-0.060 core plugs. Whatever you do, don't hammer on the plug edge to Install it. This distorts its<br />

inch for <strong>429</strong>/460s. Check this using feeler edge and increases the likelihood <strong>of</strong> a leak.<br />

gages and a straight edge or the thrust<br />

plate like this.<br />

Install the Bearings-Start with the front<br />

or rear bearing and work toward the center<br />

from the opposite end <strong>of</strong> the block.<br />

When you finish installing the center<br />

bearing, install the -remaining two bearings<br />

by working from the opposite end. The<br />

reason is, the farther you are from the<br />

bearing-relative to its position in the<br />

block-the more accurate the installation<br />

tool can be lined up with the centerline<br />

<strong>of</strong> the cam-bearing bore regardless <strong>of</strong><br />

whether it's self-centering or not. You'll<br />

have the bores at the opposite end <strong>of</strong> the<br />

block from the bearing you're installing<br />

to use as a reference to line up the<br />

bearing.<br />

<strong>To</strong> install a bearing, select the one<br />

which fits the location you want to start<br />

with. Although obvious, most bearing<br />

manufacturers list bearing locations with<br />

each part number on the box. Cross-reference<br />

these numbers with those on the<br />

back-side <strong>of</strong> the bearing insert to confirm<br />

their locations. This is also a good check<br />

to make sure you have the right bearings.<br />

I once got a Buick V-6 bearing mixed in<br />

with four <strong>351C</strong> bearings!<br />

Begin installing the first bearing insert<br />

by slipping it over the mandrel. If you<br />

have the expansion-type mandrel, you'll<br />

have to expand it so it fits snugly in the<br />

ID <strong>of</strong> the bearing. With the solid type,<br />

select one that fits the bearing ID. Wrap<br />

some masking tape around the mandrel if<br />

it's a little loose. Also apply some oil to<br />

the mandrel.<br />

With the pull or drive rod handy, position<br />

the bearing and mandrel over the<br />

bearing bore so the oil hole/s in the insert<br />

line up with those in the block-so they<br />

will line up after the bearing is installed.<br />

Use sealer on the cam plug. It seals oil and<br />

is considerably more difficult to get to with<br />

the engine in place, so a leaky cam plug<br />

presents a big problem once the engine is<br />

installed. This engine is fully assembled<br />

because an engine stand was used to support<br />

it during its assembly making it<br />

impossible to install the cam plug. You'll<br />

have the same problem if you use a stand,<br />

so don't forget the cam plug.<br />

ENGINE ASSEMBLY 93