Tsunami - Beckman Institute Laser Resource Center

Tsunami - Beckman Institute Laser Resource Center

Tsunami - Beckman Institute Laser Resource Center

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Tsunami</strong><br />

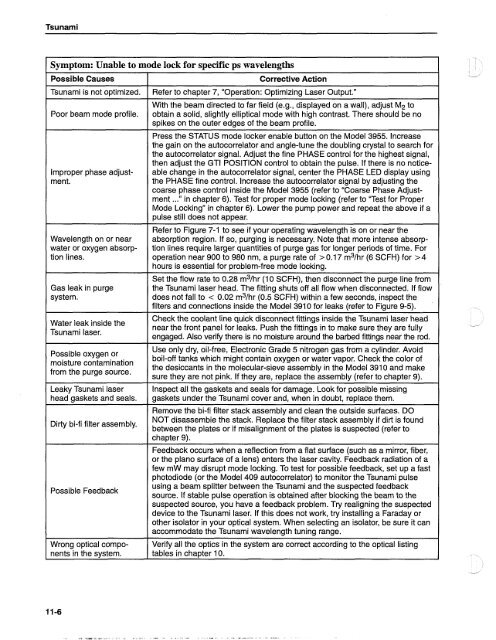

Symptom: Unable to mode lock for specific ps wavelengths<br />

Possible Causes<br />

<strong>Tsunami</strong> is not optimized.<br />

Poor beam mode profile.<br />

Improper phase adjustment.<br />

Wavelength on or near<br />

water or oxygen absorption<br />

lines.<br />

Gas leak in purge<br />

system.<br />

Water leak inside the<br />

<strong>Tsunami</strong> laser.<br />

Possible oxygen or<br />

moisture contamination<br />

from the purge source.<br />

Leaky <strong>Tsunami</strong> laser<br />

head gaskets and seals.<br />

Dirty hi-fi<br />

Possible Feedback<br />

assembly'<br />

Wrong optical components<br />

in the system.<br />

Corrective Action<br />

Refer to chapter 7, "Operation: Optimizing <strong>Laser</strong> Output,"<br />

With the beam directed to far field (e.g., displayed on a wall), adjust M2 to<br />

obtain a solid, slightly elliptical mode with high contrast. There should be no<br />

spikes on the outer edges of the beam profile.<br />

Press the STATUS mode locker enable button on the Model 3955. lncrease<br />

the gain on the autocorrelator and angle-tune the doubling crystal to search for<br />

the autocorrelator signal. Adjust the fine PHASE control for the highest signal,<br />

then adjust the GTI POSITION control to obtain the pulse. If there is no noticeable<br />

change in the autocorrelator signal, center the PHASE LED display using<br />

the PHASE fine control. Increase the autocorrelator signal by adjusting the<br />

coarse phase control inside the Model 3955 (refer to "Coarse Phase Adjustment<br />

..." in chapter 6). Test for proper mode locking (refer to "Test for Proper<br />

Mode Locking" in chapter 6). Lower the pump power and repeat the above if a<br />

pulse still does not appear.<br />

Refer to Figure 7-1 to see if your operating wavelength is on or near the<br />

absorption region. If so, purging is necessary. Note that more intense absorption<br />

lines require larger quantities of purge gas for longer periods of time. For<br />

operation near 900 to 980 nm, a purge rate of > 0.1 7 m3/hr (6 SCFH) for >4<br />

hours is essential for problem-free mode locking.<br />

Set the flow rate to 0.28 m3/hr (10 SCFH), then disconnect the purge line from<br />

the <strong>Tsunami</strong> laser head. The fitting shuts off all flow when disconnected. If flow<br />

does not fall to < 0.02 m3/hr (0.5 SCFH) within a few seconds, inspect the<br />

filters and connections inside the Model 391 0 for leaks (refer to Figure 9-5).<br />

Check the coolant line quick disconnect fittings inside the <strong>Tsunami</strong> laser head<br />

near the front panel for leaks. Push the fittings in to make sure they are fully<br />

engaged. Also verify there is no moisture around the barbed fittings near the rod.<br />

Use only dry, oil-free, Electronic Grade 5 nitrogen gas from a cylinder. Avoid<br />

boil-off tanks which might contain oxygen or water vapor. Check the color of<br />

the desiccants in the molecular-sieve assembly in the Model 391 0 and make<br />

sure they are not pink. If they are, replace the assembly (refer to chapter 9).<br />

Inspect all the gaskets and seals for damage. Look for possible missing<br />

gaskets under the <strong>Tsunami</strong> cover and, when in doubt, replace them.<br />

Remove the bi-fi filter stack assembly and clean the outside surfaces. DO<br />

NOT disassemble the stack. Replace the filter stack assembly if dirt is found<br />

between the plates or if misalignment of the plates is suspected (refer to<br />

chapter 9).<br />

Feedback occurs when a reflection from a flat surface (such as a mirror, fiber,<br />

or the plano surface of a lens) enters the laser cavity. Feedback radiation of a<br />

few mW may disrupt mode locking. To test for possible feedback, set up a fast<br />

photodiode (or the Model 409 autocorrelator) to monitor the <strong>Tsunami</strong> pulse<br />

using a beam splitter between the <strong>Tsunami</strong> and the suspected feedback<br />

source. If stable pulse operation is obtained after blocking the beam to the<br />

suspected source, you have a feedback problem. Try realigning the suspected<br />

device to the <strong>Tsunami</strong> laser. If this does not work, try installing a Faraday or<br />

other isolator in your optical system. When selecting an isolator, be sure it can<br />

accommodate the <strong>Tsunami</strong> wavelength tuning range.<br />

Verify all the optics in the system are correct according to the optical listing<br />

tables in chapter 10.