Tsunami - Beckman Institute Laser Resource Center

Tsunami - Beckman Institute Laser Resource Center

Tsunami - Beckman Institute Laser Resource Center

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Service and Repair<br />

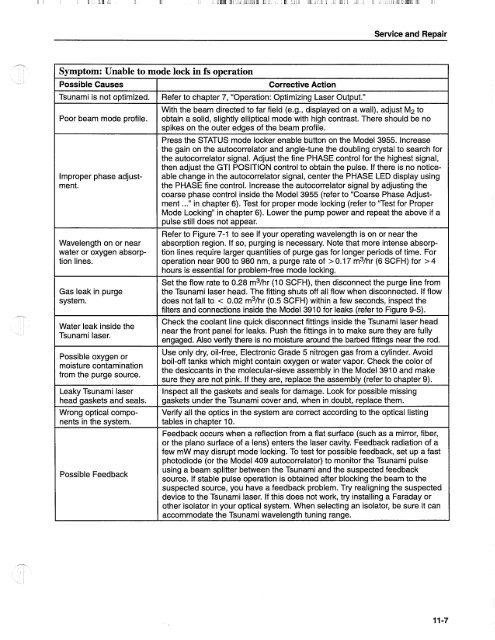

Symptom: Unable to mode lock in fs operation<br />

Possible Causes<br />

<strong>Tsunami</strong> is not optimized.<br />

Poor beam mode profile.<br />

Improper phase adjustment.<br />

Wavelength on or near<br />

water or oxygen absorption<br />

lines.<br />

Gas leak in purge<br />

system.<br />

Water leak inside the<br />

<strong>Tsunami</strong> laser.<br />

Possible oxygen or<br />

moisture contamination<br />

from the purge source.<br />

Leaky <strong>Tsunami</strong> laser<br />

head gaskets and seals.<br />

Wrong optical components<br />

in the system.<br />

Possible Feedback<br />

Corrective Action<br />

Refer to chapter 7, "Operation: Optimizing <strong>Laser</strong> Output."<br />

With the beam directed to far field (e.g., displayed on a wall), adjust M2 to<br />

obtain a solid, slightly elliptical mode with high contrast. There should be no<br />

spikes on the outer edges of the beam profile.<br />

Press the STATUS mode locker enable button on the Model 3955. lncrease<br />

the gain on the autocorrelator and angle-tune the doubling crystal to search for<br />

the autocorrelator signal. Adjust the fine PHASE control for the highest signal,<br />

then adjust the GTI POSITION control to obtain the pulse. If there is no noticeable<br />

change in the autocorrelator signal, center the PHASE LED display using<br />

the PHASE fine control. Increase the autocorrelator signal by adjusting the<br />

coarse phase control inside the Model 3955 (refer to "Coarse Phase Adjustment<br />

..." in chapter 6). Test for proper mode locking (refer to "Test for Proper<br />

Mode Locking" in chapter 6). Lower the pump power and repeat the above if a<br />

pulse still does not appear.<br />

Refer to Figure 7-1 to see if your operating wavelength is on or near the<br />

absorption region. If so, purging is necessary. Note that more intense absorption<br />

lines require larger quantities of purge gas for longer periods of time. For<br />

operation near 900 to 980 nm, a purge rate of > 0.17 m3/hr (6 SCFH) for >4<br />

hours is essential for problem-free mode locking.<br />

Set the flow rate to 0.28 m3/hr (1 0 SCFH), then disconnect the purge line from<br />

the <strong>Tsunami</strong> laser head. The fitting shuts off all flow when disconnected. If flow<br />

does not fall to < 0.02 m3/hr (0.5 SCFH) within a few seconds, inspect the<br />

filters and connections inside the Model 3910 for leaks (refer to Figure 9-5).<br />

Check the coolant line quick disconnect fittings inside the <strong>Tsunami</strong> laser head<br />

near the front panel for leaks. Push the fittings in to make sure they are fully<br />

engaged. Also verify there is no moisture around the barbed fittings near the rod.<br />

Use only dry, oil-free, Electronic Grade 5 nitrogen gas from a cylinder. Avoid<br />

boil-off tanks which might contain oxygen or water vapor. Check the color of<br />

the desiccants in the molecular-sieve assembly in the Model 391 0 and make<br />

sure they are not pink. If they are, replace the assembly (refer to chapter 9).<br />

Inspect all the gaskets and seals for damage. Look for possible missing<br />

gaskets under the <strong>Tsunami</strong> cover and, when in doubt, replace them.<br />

Verify all the optics in the system are correct according to the optical listing<br />

tables in chapter 10.<br />

Feedback occurs when a reflection from a flat surface (such as a mirror, fiber,<br />

or the plano surface of a lens) enters the laser cavity. Feedback radiation of a<br />

few mW may disrupt mode locking. To test for possible feedback, set up a fast<br />

photodiode (or the Model 409 autocorrelator) to monitor the <strong>Tsunami</strong> pulse<br />

using a beam splitter between the <strong>Tsunami</strong> and the suspected feedback<br />

source. If stable pulse operation is obtained after blocking the beam to the<br />

suspected source, you have a feedback problem. Try realigning the suspected<br />

device to the <strong>Tsunami</strong> laser. If this does not work, try installing a Faraday or<br />

other isolator in your optical system. When selecting an isolator, be sure it can<br />

accommodate the <strong>Tsunami</strong> wavelength tuning range.