- Page 1:

EQUIPPED WITH BOBCAT INTERLOCK CONT

- Page 5 and 6:

FOREWORD . . . . . . . . . . . . .

- Page 7 and 8:

17. Inspect the air cleaner for dam

- Page 9 and 10:

SAFETY INSTRUCTIONS Instructions ar

- Page 11 and 12:

SERIAL NUMBER LOCATIONS Always use

- Page 13 and 14:

All 853 & 853H Bobcat loaders are e

- Page 15 and 16:

PREVENTIVE MAINTENANCE Page Number

- Page 17 and 18:

SERVICE SCHEDULE Maintenance work m

- Page 19 and 20:

TRANSPORTING THE LOADER Procedure A

- Page 21 and 22:

LIFT ARM SUPPORT DEVICE Never work

- Page 23 and 24:

OPERATOR CAB (Cont’d) Lowering th

- Page 25 and 26:

AIR CLEANER SERVICE Replacing Filte

- Page 27 and 28:

FUEL SYSTEM Fuel Specifications Use

- Page 29 and 30:

ENGINE LUBRICATION SYSTEM Checking

- Page 31 and 32:

ENGINE COOLING SYSTEM Cleaning the

- Page 33 and 34:

USING A BOOSTER BATTERY (Jump Start

- Page 35 and 36:

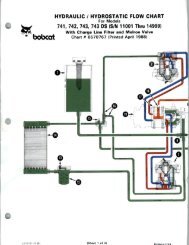

HYDRAULIC/HYDROSTATIC SYSTEM (Cont

- Page 37 and 38:

SPARK ARRESTOR MUFFLER Cleaning Pro

- Page 39 and 40:

FINAL DRIVE TRANSMISSION (CHAINCASE

- Page 41 and 42:

LUBRICATING THE LOADER (Cont’d) P

- Page 43 and 44:

REMOTE START SWITCH (Cont’d) Proc

- Page 45 and 46:

HYDRAULIC SYSTEM Page Number BUCKET

- Page 47 and 48:

1 FLUID RESERVOIR: Cap . . . . 15.5

- Page 49 and 50:

HYDRAULIC/HYDROSTATIC SCHEMATIC 853

- Page 51 and 52:

HYDRAULIC SYSTEM TROUBLESHOOTING Ch

- Page 53 and 54:

LIFT CYLINDER(S) Checking the Lift

- Page 55 and 56:

TILT CYLINDER Checking the Tilt Cyl

- Page 57 and 58:

HYDRAULIC CYLINDER Lift Cylinder Id

- Page 59 and 60:

HYDRAULIC CYLINDER (Cont’d) Disas

- Page 61 and 62:

HYDRAULIC CYLINDER (Cont’d) Disas

- Page 63 and 64:

HYDRAULIC CYLINDER (Cont’d) Assem

- Page 65 and 66:

HYDRAULIC CYLINDER (Cont’d) Assem

- Page 67 and 68:

MAIN RELIEF VALVE Checking the Main

- Page 69 and 70:

MAIN RELIEF VALVE (Cont’d) Remova

- Page 71 and 72:

DUAL PRESSURE MAIN RELIEF VALVE - 8

- Page 73 and 74:

DUAL PRESSURE MAIN RELIEF VALVE - 8

- Page 75 and 76:

SELECT VALVE (G.E.M. Block) 853H Ch

- Page 77 and 78:

HYDRAULIC CONTROL VALVE (Cont’d)

- Page 79 and 80:

HYDRAULIC CONTROL VALVE (Cont’d)

- Page 81 and 82:

HYDRAULIC CONTROL VALVE (Cont’d)

- Page 83 and 84:

HYDRAULIC CONTROL VALVE (Cont’d)

- Page 85 and 86:

HYDRAULIC CONTROL VALVE (Cont’d)

- Page 87 and 88:

HYDRAULIC CONTROL VALVE (Cont’d)

- Page 89 and 90:

HYDRAULIC CONTROL VALVE (Cont’d)

- Page 91 and 92:

HYDRAULIC CONTROL VALVE (Cont’d)

- Page 93 and 94:

HYDRAULIC PUMP Checking the Output

- Page 95 and 96:

HYDRAULIC PUMP (Cont’d) Parts Ide

- Page 97 and 98:

HYDRAULIC PUMP (Cont’d) Disassemb

- Page 99 and 100:

HYDRAULIC PUMP (Cont’d) Assembly

- Page 101 and 102:

HYDRAULIC PUMP (Double Gear) 853H C

- Page 103 and 104:

HYDRAULIC PUMP (Double Gear) 853H (

- Page 105 and 106:

HYDRAULIC PUMP (Double Gear) 853H (

- Page 107 and 108:

HYDRAULIC PUMP (Double Gear) 853H (

- Page 109 and 110:

HYDRAULIC PUMP (Double Gear) 853H (

- Page 111 and 112:

HYDRAULIC PUMP (Double Gear) 853H (

- Page 113 and 114:

HYDRAULIC FLUID RESERVOIR Removal a

- Page 115 and 116:

HYDRAULIC FILTER HOUSING Removal an

- Page 117 and 118:

PEDAL INTERLOCK LINKAGE Removal and

- Page 119 and 120:

Revised June 96 HYDROSTATIC SYSTEM

- Page 121 and 122:

TROUBLESHOOTING Chart The following

- Page 123 and 124:

FRONT PANEL Removal and Installatio

- Page 125 and 126:

STEERING LEVERS Disassembly and Ass

- Page 127 and 128:

STEERING LEVERS (Cont’d) Pre-Adju

- Page 129 and 130:

STEERING LEVERS (Cont’d) Adjustin

- Page 131 and 132:

STEERING LEVERS (Cont’d) Adjustin

- Page 133 and 134:

HYDROSTATIC MOTOR Removal and Insta

- Page 135 and 136:

HYDROSTATIC MOTOR (Cont’d) Disass

- Page 137 and 138:

HYDROSTATIC MOTOR (Cont’d) Disass

- Page 139 and 140:

HYDROSTATIC MOTOR (Cont’d) Disass

- Page 141 and 142:

HYDROSTATIC MOTOR (Cont’d) Assemb

- Page 143 and 144:

HYDROSTATIC MOTOR (Cont’d) 853, 8

- Page 145 and 146:

HYDROSTATIC PUMP Removal and Instal

- Page 147 and 148:

HYDROSTATIC PUMP (Cont’d) Repleni

- Page 149 and 150:

HYDROSTATIC PUMP (Cont’d) Parts I

- Page 151 and 152:

HYDROSTATIC PUMP (Cont’d) Parts I

- Page 153 and 154:

HYDROSTATIC PUMP (Cont’d) Hydraul

- Page 155 and 156:

HYDROSTATIC PUMP (Cont’d) Charge

- Page 157 and 158:

HYDROSTATIC PUMP (Cont’d) Disasse

- Page 159 and 160:

HYDROSTATIC PUMP (Cont’d) Disasse

- Page 161 and 162:

HYDROSTATIC PUMP (Cont’d) Disasse

- Page 163 and 164:

HYDROSTATIC PUMP (Cont’d) Disasse

- Page 165 and 166:

HYDROSTATIC PUMP (Cont’d) Inspect

- Page 167 and 168:

HYDROSTATIC PUMP (Cont’d) Assembl

- Page 169 and 170:

HYDROSTATIC PUMP (Cont’d) Assembl

- Page 171 and 172:

HYDROSTATIC PUMP (Cont’d) Assembl

- Page 173 and 174:

HYDROSTATIC PUMP (Cont’d) Assembl

- Page 175 and 176:

HYDROSTATIC PUMP (Cont’d) Assembl

- Page 177 and 178:

HYDROSTATIC PUMP (Cont’d) Hydraul

- Page 179 and 180:

HYDROSTATIC PUMP (Cont’d) Hydrost

- Page 181 and 182:

DRIVE BELT Adjusting the Drive Belt

- Page 183 and 184:

DRIVE BELT TENSIONER PULLEY Removal

- Page 185 and 186:

DRIVE BELT TENSIONER PULLEY (Cont

- Page 187 and 188:

DRIVE BELT TENSIONER PULLEY (Cont

- Page 189 and 190:

DRIVE BELT TENSIONER PULLEY (Cont

- Page 191 and 192:

OIL COOLER Removal and Installation

- Page 193 and 194:

DRIVE SYSTEM Page Number AXLE SEAL

- Page 195 and 196:

DRIVE SYSTEM PARKING BRAKE PEDAL Re

- Page 197 and 198:

PARKING BRAKE DISC Removal and Inst

- Page 199 and 200:

FRONT CHAINCASE COVER Removal and I

- Page 201 and 202:

AXLE SEAL (Cont’d) Removal and In

- Page 203 and 204:

AXLE, BEARINGS AND SPROCKET (Cont

- Page 205 and 206:

AXLE, BEARING AND SPROCKET (Cont’

- Page 207 and 208:

REDUCTION GEARCASE (Cont’d) Remov

- Page 209 and 210:

REDUCTION GEARCASE (Cont’d) Disas

- Page 211 and 212:

REDUCTION GEARCASE (Cont’d) Disas

- Page 213 and 214:

REDUCTION GEARCASE (Cont’d) Assem

- Page 215 and 216:

REDUCTION GEARCASE (Cont’d) Assem

- Page 217 and 218:

DRIVE CHAIN 853, 853H BICS Service

- Page 219 and 220:

MAIN FRAME Page Number BOB-TACH Bob

- Page 221 and 222:

MAIN FRAME SEAT BAR Removal and Ins

- Page 223 and 224:

SEAT BAR (Cont’d) Removal and Ins

- Page 225 and 226:

OPERATOR CAB GAS CYLINDER Removal a

- Page 227 and 228:

OPERATOR CAB Removal and Installati

- Page 229 and 230:

OPERATOR SEAT Removal and Installat

- Page 231 and 232:

BOB-TACH (Cont’d) Removal and Ins

- Page 233 and 234:

BOB-TACH (Cont’d) Bob-Tach Lever

- Page 235 and 236:

REAR GRILL Removal and Installation

- Page 237 and 238:

REAR DOOR (Cont’d) Hood Removal a

- Page 239 and 240:

FUEL TANK (Cont’d) Removal and In

- Page 241 and 242:

ELECTRICAL SYSTEM Page Number ALTER

- Page 274 and 275:

WIRE LEGEND NO.'s COLOR GAUGE PARTS

- Page 276 and 277:

WIRE LEGEND NO.'s COLOR GAUGE 12 Or

- Page 278 and 279:

ELECTRICAL SYSTEM TROUBLESHOOTING C

- Page 280 and 281:

BATTERY Removal and Installation Ba

- Page 282 and 283:

ALTERNATOR (Cont’d) Alternator Re

- Page 284 and 285:

ALTERNATOR (Cont’d) Disassembly a

- Page 286 and 287:

ALTERNATOR (Cont’d) Assembly Reve

- Page 288 and 289:

STARTER (Cont’d) Checking the Sta

- Page 290 and 291:

STARTER (Cont’d) Disassembly and

- Page 292 and 293:

STARTER (Cont’d) Cleaning and Ins

- Page 294 and 295:

FRONT LIGHTS Removal and Installati

- Page 296 and 297:

ENGINE SERVICE Page Number AIR CLEA

- Page 298 and 299:

ENGINE SERVICE TROUBLESHOOTING Char

- Page 300 and 301:

RADIATOR Removal and Installation O

- Page 302 and 303:

COOLANT RECOVERY TANK Removal and I

- Page 304 and 305:

AIR CLEANER HOUSING Removal and Ins

- Page 306 and 307:

BLOWER HOUSING/FAN GEARBOX (Cont’

- Page 308 and 309:

BLOWER FAN Removal and Installation

- Page 310 and 311:

FAN GEARBOX (Cont’d) Disassembly

- Page 312 and 313:

FAN GEARBOX (Cont’d) Disassembly

- Page 314 and 315:

FAN GEARBOX (Cont’d) Disassembly

- Page 316 and 317:

FAN GEARBOX (Cont’d) Assembly (Co

- Page 318 and 319:

FAN GEARBOX (Cont’d) Assembly (Co

- Page 320 and 321:

FAN GEARBOX (Cont’d) 853, 853H BI

- Page 322 and 323:

FAN GEARBOX (Cont’d) Checking Bac

- Page 324 and 325:

ENGINE (Cont’d) Removal and Insta

- Page 326 and 327: ENGINE (Cont’d) Removal and Insta

- Page 328 and 329: ENGINE (Cont’d) Removal and Insta

- Page 330 and 331: ENGINE (Cont’d) Engine Mount Repl

- Page 332 and 333: BELT SHIELD Removal and Installatio

- Page 334 and 335: GLOW PLUGS Removal and Installation

- Page 336 and 337: FUEL INJECTION PUMP (Cont’d) Remo

- Page 338 and 339: FUEL INJECTION PUMP (Cont’d) Remo

- Page 340 and 341: FUEL INJECTION PUMP (Cont’d) Timi

- Page 342 and 343: FUEL INJECTOR NOZZLES (Cont’d) Re

- Page 344 and 345: CYLINDER HEAD Removal and Installat

- Page 346 and 347: VALVES, VALVE SEAT AND GUIDE Remova

- Page 348 and 349: VALVES, VALVE SEAT AND GUIDE (Cont

- Page 350 and 351: PISTON AND CONNECTING ROD Removal R

- Page 352 and 353: PISTON AND CONNECTING ROD (Cont’d

- Page 354 and 355: PISTON AND CONNECTING ROD (Cont’d

- Page 356 and 357: CYLINDER LINERS Checking the Cylind

- Page 358 and 359: MAIN BEARINGS (Cont’d) Installati

- Page 360 and 361: CRANKSHAFT Removal and Installation

- Page 362 and 363: CRANKSHAFT GEAR Removal and Install

- Page 364 and 365: TIMING GEARCASE COVER Removal and I

- Page 366 and 367: IDLER GEAR AND HUB Removal Remove t

- Page 368 and 369: FUEL INJECTION PUMP IDLER GEAR Remo

- Page 370 and 371: TIMING GEARCASE 853, 853H BICS Serv

- Page 372 and 373: CAMSHAFT (Cont’d) Camshaft Bearin

- Page 374 and 375: OIL PAN Removal Remove the oil drai

- Page 378 and 379: WATER PUMP Removal and Installation

- Page 380 and 381: WATER PUMP (Cont’d) Assembly (Con

- Page 382 and 383: WATER JACKET TUBE Removal and Insta

- Page 384 and 385: SYSTEMS ANALYSIS Page Number BICS S

- Page 386 and 387: BOBCAT INTERLOCK CONTROL SYSTEM (BI

- Page 388 and 389: BOBCAT INTERLOCK CONTROL SYSTEM (BI

- Page 390 and 391: BOBCAT INTERLOCK CONTROL SYSTEM (BI

- Page 392 and 393: BOBCAT INTERLOCK CONTROL SYSTEM (BI

- Page 394 and 395: BICS SYSTEM CONTROLLER (Cont’d) C

- Page 396 and 397: SEAT BAR SENSOR (Cont’d) Seat Bar

- Page 398 and 399: SEAT SENSOR (Cont’d) Seat Sensor

- Page 400 and 401: LIFT LOCK BY-PASS VALVE Removal and

- Page 402 and 403: TILT LOCK VALVE Removal and Install

- Page 404 and 405: BOSS® DIAGNOSTIC TOOL Procedure Th

- Page 406 and 407: SERVICE CODES (Cont’d) The follow

- Page 408 and 409: TROUBLESHOOTING THE BOSS® & LCD DI

- Page 410 and 411: BOSS® INSTRUMENT PANEL Removal and

- Page 412 and 413: PWM MODULE (Cont’d) Description (

- Page 414 and 415: PWM CONTROL HANDLE Handle Testing T

- Page 416 and 417: SPECIFICATIONS Page Number DECIMAL

- Page 418 and 419: LOADER SPECIFICATIONS LOADER DIMENS

- Page 420 and 421: ENGINE SPECIFICATIONS All dimension

- Page 422 and 423: ENGINE SPECIFICATIONS (Cont’d) Al

- Page 424 and 425: TORQUE SPECIFICATIONS FOR LOADER Sp

- Page 426 and 427:

HYDRAULIC/HYDROSTATIC FLUID SPECIFI

- Page 428 and 429:

DECIMAL AND MILLIMETER EQUIVALENTS

- Page 430:

AFFECTING: Product BOBCAT LOADER Mo

- Page 434:

AFFECTING: Product BOBCAT LOADER Mo

- Page 437 and 438:

TAKE OUT PUT IN 853 BICS - OPERATOR