Our performance in 2009 - Sappi

Our performance in 2009 - Sappi

Our performance in 2009 - Sappi

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

14<br />

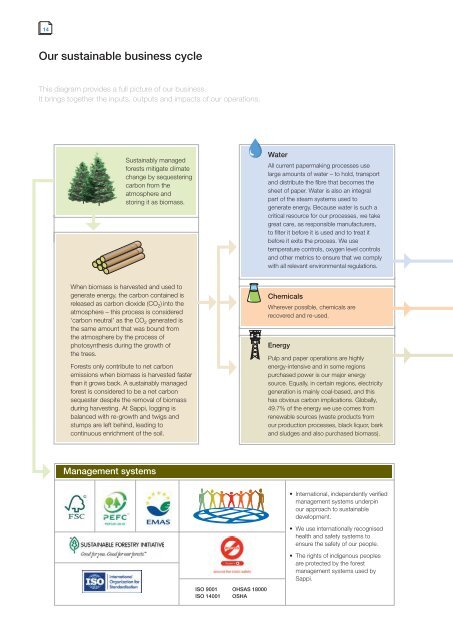

<strong>Our</strong> susta<strong>in</strong>able bus<strong>in</strong>ess cycle<br />

This diagram provides a full picture of our bus<strong>in</strong>ess.<br />

It br<strong>in</strong>gs together the <strong>in</strong>puts, outputs and impacts of our operations.<br />

Management systems<br />

Susta<strong>in</strong>ably managed<br />

forests mitigate climate<br />

change by sequester<strong>in</strong>g<br />

carbon from the<br />

atmosphere and<br />

stor<strong>in</strong>g it as biomass.<br />

When biomass is harvested and used to<br />

generate energy, the carbon conta<strong>in</strong>ed is<br />

released as carbon dioxide (CO 2) <strong>in</strong>to the<br />

atmosphere – this process is considered<br />

‘carbon neutral’ as the CO 2 generated is<br />

the same amount that was bound from<br />

the atmosphere by the process of<br />

photosynthesis dur<strong>in</strong>g the growth of<br />

the trees.<br />

Forests only contribute to net carbon<br />

emissions when biomass is harvested faster<br />

than it grows back. A susta<strong>in</strong>ably managed<br />

forest is considered to be a net carbon<br />

sequester despite the removal of biomass<br />

dur<strong>in</strong>g harvest<strong>in</strong>g. At <strong>Sappi</strong>, logg<strong>in</strong>g is<br />

balanced with re-growth and twigs and<br />

stumps are left beh<strong>in</strong>d, lead<strong>in</strong>g to<br />

cont<strong>in</strong>uous enrichment of the soil.<br />

ISO 9001 OHSAS 18000<br />

ISO 14001 OSHA<br />

Water<br />

All current papermak<strong>in</strong>g processes use<br />

large amounts of water – to hold, transport<br />

and distribute the fibre that becomes the<br />

sheet of paper. Water is also an <strong>in</strong>tegral<br />

part of the steam systems used to<br />

generate energy. Because water is such a<br />

critical resource for our processes, we take<br />

great care, as responsible manufacturers,<br />

to filter it before it is used and to treat it<br />

before it exits the process. We use<br />

temperature controls, oxygen level controls<br />

and other metrics to ensure that we comply<br />

with all relevant environmental regulations.<br />

Chemicals<br />

Wherever possible, chemicals are<br />

recovered and re-used.<br />

Energy<br />

Pulp and paper operations are highly<br />

energy-<strong>in</strong>tensive and <strong>in</strong> some regions<br />

purchased power is our major energy<br />

source. Equally, <strong>in</strong> certa<strong>in</strong> regions, electricity<br />

generation is ma<strong>in</strong>ly coal-based, and this<br />

has obvious carbon implications. Globally,<br />

49.7% of the energy we use comes from<br />

renewable sources (waste products from<br />

our production processes, black liquor, bark<br />

and sludges and also purchased biomass).<br />

International, <strong>in</strong>dependently verified<br />

management systems underp<strong>in</strong><br />

our approach to susta<strong>in</strong>able<br />

development.<br />

We use <strong>in</strong>ternationally recognised<br />

health and safety systems to<br />

ensure the safety of our people.<br />

The rights of <strong>in</strong>digenous peoples<br />

are protected by the forest<br />

management systems used by<br />

<strong>Sappi</strong>.