Our performance in 2009 - Sappi

Our performance in 2009 - Sappi

Our performance in 2009 - Sappi

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

32<br />

Review of operations | <strong>Sappi</strong> F<strong>in</strong>e Paper cont<strong>in</strong>ued<br />

<strong>Sappi</strong> F<strong>in</strong>e Paper’s ma<strong>in</strong> product l<strong>in</strong>e, coated graphic paper, contributes 67% of group<br />

sales by value, and is used <strong>in</strong> produc<strong>in</strong>g calendars, catalogues, brochures, books, premium<br />

magaz<strong>in</strong>es, direct mail<strong>in</strong>gs and annual reports. <strong>Sappi</strong> F<strong>in</strong>e Paper also produces a range of<br />

uncoated graphic and bus<strong>in</strong>ess paper, coated and uncoated speciality paper, like that used<br />

<strong>in</strong> flexible packag<strong>in</strong>g, and cast<strong>in</strong>g release paper, used <strong>in</strong> the manufacture of synthetic<br />

leather and decorative lam<strong>in</strong>ate products. Total paper sales represent 84% of group sales.<br />

The geographic spread of our operations allows us to optimise our global knowledge of<br />

market developments, operat<strong>in</strong>g best practices and technology. <strong>Sappi</strong> F<strong>in</strong>e Paper is<br />

approximately 63% <strong>in</strong>tegrated <strong>in</strong> pulp, with Europe a major net buyer of pulp and North<br />

America a net seller of pulp.<br />

Europe<br />

As we completed the acquisition at the end of December 2008 demand across Europe began<br />

fall<strong>in</strong>g as a result of the global economic downturn. We acted quickly to curtail output to match<br />

demand and took account of the unprecedented market conditions as we <strong>in</strong>tegrated the new<br />

bus<strong>in</strong>ess.<br />

The European team was well prepared for the <strong>in</strong>tegration, which went smoothly. We placed<br />

particular emphasis on customer relations and service and our market shares for coated f<strong>in</strong>e<br />

paper and coated magaz<strong>in</strong>e paper, at year end, were <strong>in</strong> l<strong>in</strong>e with the theoretical market shares<br />

of the two bus<strong>in</strong>esses comb<strong>in</strong>ed. It is pleas<strong>in</strong>g that our people came together enthusiastically<br />

and our team <strong>in</strong> Europe is highly motivated and focused on further optimis<strong>in</strong>g our bus<strong>in</strong>ess.<br />

We achieved synergy benefits <strong>in</strong> excess of the r60 million target for the n<strong>in</strong>e months to<br />

September <strong>2009</strong>, and we expect to achieve the full target of r120 million a year ahead of the<br />

three-year timeframe.<br />

The team is currently work<strong>in</strong>g with customers to f<strong>in</strong>d ways to improve their profitability and ours,<br />

based on improv<strong>in</strong>g our understand<strong>in</strong>g of their needs and serv<strong>in</strong>g them better while reduc<strong>in</strong>g<br />

complexity and cost throughout the supply cha<strong>in</strong>. We expect these <strong>in</strong>itiatives to deliver significant<br />

benefits over the next few years.<br />

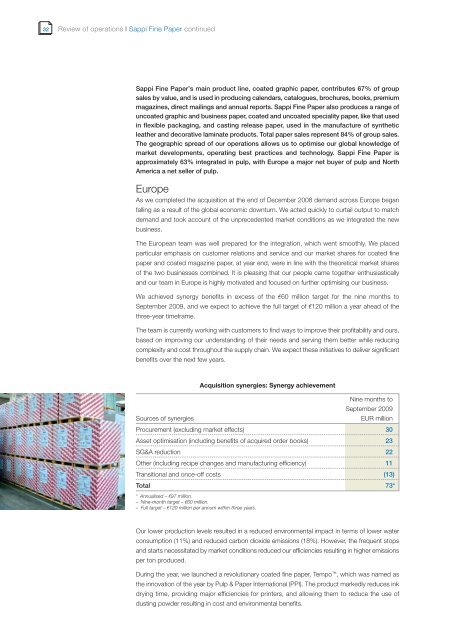

Acquisition synergies: Synergy achievement<br />

Sources of synergies<br />

N<strong>in</strong>e months to<br />

September <strong>2009</strong><br />

EUR million<br />

Procurement (exclud<strong>in</strong>g market effects) 30<br />

Asset optimisation (<strong>in</strong>clud<strong>in</strong>g benefits of acquired order books) 23<br />

SG&A reduction 22<br />

Other (<strong>in</strong>clud<strong>in</strong>g recipe changes and manufactur<strong>in</strong>g efficiency) 11<br />

Transitional and once-off costs (13)<br />

Total 73*<br />

* Annualised – r97 million.<br />

– N<strong>in</strong>e-month target – r60 million.<br />

– Full target – r120 million per annum with<strong>in</strong> three years.<br />

<strong>Our</strong> lower production levels resulted <strong>in</strong> a reduced environmental impact <strong>in</strong> terms of lower water<br />

consumption (11%) and reduced carbon dioxide emissions (18%). However, the frequent stops<br />

and starts necessitated by market conditions reduced our efficiencies result<strong>in</strong>g <strong>in</strong> higher emissions<br />

per ton produced.<br />

Dur<strong>in</strong>g the year, we launched a revolutionary coated f<strong>in</strong>e paper, Tempo, which was named as<br />

the <strong>in</strong>novation of the year by Pulp & Paper International (PPI). The product markedly reduces <strong>in</strong>k<br />

dry<strong>in</strong>g time, provid<strong>in</strong>g major efficiencies for pr<strong>in</strong>ters, and allow<strong>in</strong>g them to reduce the use of<br />

dust<strong>in</strong>g powder result<strong>in</strong>g <strong>in</strong> cost and environmental benefits.