OMRON Sysdrive 3G3HV - Detector Cooling Section

OMRON Sysdrive 3G3HV - Detector Cooling Section

OMRON Sysdrive 3G3HV - Detector Cooling Section

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

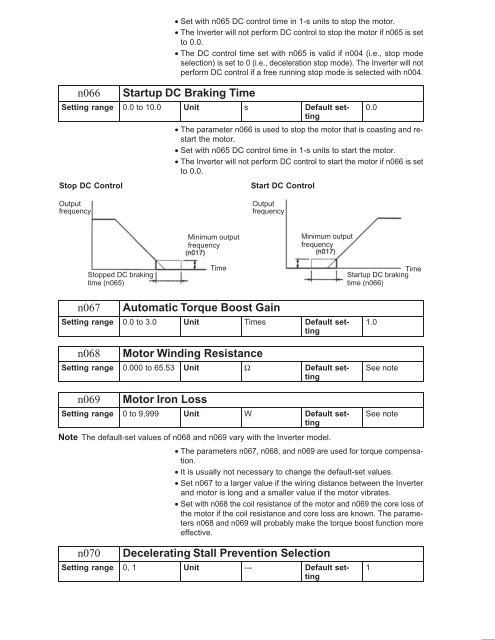

n066<br />

• Set with n065 DC control time in 1-s units to stop the motor.<br />

• The Inverter will not perform DC control to stop the motor if n065 is set<br />

to 0.0.<br />

• The DC control time set with n065 is valid if n004 (i.e., stop mode<br />

selection) is set to 0 (i.e., deceleration stop mode). The Inverter will not<br />

perform DC control if a free running stop mode is selected with n004.<br />

Startup DC Braking Time<br />

Setting range 0.0 to 10.0 Unit s Default setting<br />

0.0<br />

• The parameter n066 is used to stop the motor that is coasting and restart<br />

the motor.<br />

• Set with n065 DC control time in 1-s units to start the motor.<br />

• The Inverter will not perform DC control to start the motor if n066 is set<br />

to 0.0.<br />

Stop DC Control<br />

Start DC Control<br />

Output<br />

frequency<br />

Output<br />

frequency<br />

Minimum output<br />

frequency<br />

Minimum output<br />

frequency<br />

Stopped DC braking<br />

time (n065)<br />

Time<br />

Time<br />

Startup DC braking<br />

time (n066)<br />

n067<br />

Automatic Torque Boost Gain<br />

Setting range 0.0 to 3.0 Unit Times Default setting<br />

n068<br />

Motor Winding Resistance<br />

Setting range 0.000 to 65.53 Unit Ω Default setting<br />

1.0<br />

See note<br />

n069<br />

Motor Iron Loss<br />

Setting range 0 to 9,999 Unit W Default setting<br />

See note<br />

Note The default-set values of n068 and n069 vary with the Inverter model.<br />

• The parameters n067, n068, and n069 are used for torque compensation.<br />

• It is usually not necessary to change the default-set values.<br />

• Set n067 to a larger value if the wiring distance between the Inverter<br />

and motor is long and a smaller value if the motor vibrates.<br />

• Set with n068 the coil resistance of the motor and n069 the core loss of<br />

the motor if the coil resistance and core loss are known. The parameters<br />

n068 and n069 will probably make the torque boost function more<br />

effective.<br />

n070<br />

Decelerating Stall Prevention Selection<br />

Setting range 0, 1 Unit --- Default setting<br />

1