OMRON Sysdrive 3G3HV - Detector Cooling Section

OMRON Sysdrive 3G3HV - Detector Cooling Section

OMRON Sysdrive 3G3HV - Detector Cooling Section

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

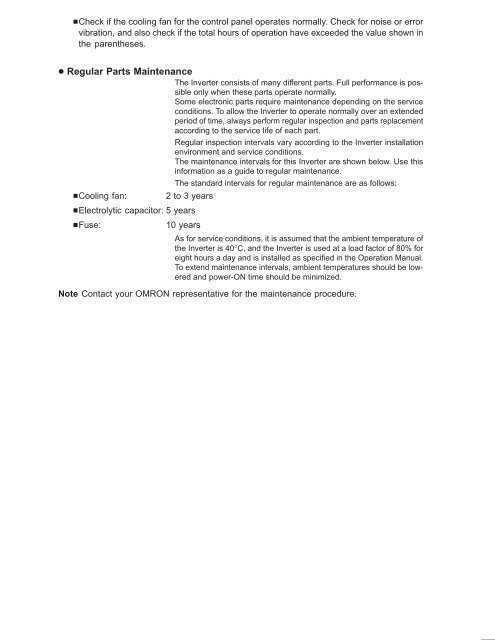

Check if the cooling fan for the control panel operates normally. Check for noise or error<br />

vibration, and also check if the total hours of operation have exceeded the value shown in<br />

the parentheses.<br />

Regular Parts Maintenance<br />

The Inverter consists of many different parts. Full performance is possible<br />

only when these parts operate normally.<br />

Some electronic parts require maintenance depending on the service<br />

conditions. To allow the Inverter to operate normally over an extended<br />

period of time, always perform regular inspection and parts replacement<br />

according to the service life of each part.<br />

Regular inspection intervals vary according to the Inverter installation<br />

environment and service conditions.<br />

The maintenance intervals for this Inverter are shown below. Use this<br />

information as a guide to regular maintenance.<br />

The standard intervals for regular maintenance are as follows:<br />

<strong>Cooling</strong> fan: 2 to 3 years<br />

Electrolytic capacitor: 5 years<br />

Fuse:<br />

10 years<br />

As for service conditions, it is assumed that the ambient temperature of<br />

the Inverter is 40°C, and the Inverter is used at a load factor of 80% for<br />

eight hours a day and is installed as specified in the Operation Manual.<br />

To extend maintenance intervals, ambient temperatures should be lowered<br />

and power-ON time should be minimized.<br />

Note Contact your <strong>OMRON</strong> representative for the maintenance procedure.