- Page 1 and 2:

HANDBOOK OF AIR CONDITIONING AND RE

- Page 3 and 4:

This book is dedicated to my dear w

- Page 5 and 6:

PREFACE TO SECOND EDITION Air condi

- Page 7 and 8:

ACKNOWLEDGMENTS PREFACE TO THE FIRS

- Page 9 and 10:

I.2 INDEX Air conditioning systems,

- Page 11 and 12:

I.4 INDEX Bernoulli equation, 17.2

- Page 13 and 14:

I.6 INDEX Chilled-water storage sys

- Page 15 and 16:

I.8 INDEX Constant-volume single-zo

- Page 17 and 18:

I.10 INDEX Discharge air temperatur

- Page 19 and 20:

I.12 INDEX Evaporative cooling syst

- Page 21 and 22:

I.14 INDEX Fault detection and diag

- Page 23 and 24:

I.16 INDEX Ice storage systems: com

- Page 25 and 26:

I.18 INDEX Packaged systems, fan-po

- Page 27 and 28:

I.20 INDEX Refrigerant flow control

- Page 29 and 30:

I.22 INDEX Silencers (Cont.) dissip

- Page 31 and 32:

I.24 INDEX Space pressurization or

- Page 33 and 34:

I.26 INDEX VAV systems, VAV cooling

- Page 35 and 36:

Preface to Second Edition xi Prefac

- Page 37 and 38:

Chapter 27. Air Conditioning System

- Page 39 and 40:

1.2 CHAPTER ONE limits for the comf

- Page 41 and 42:

1.4 CHAPTER ONE Individual Room Air

- Page 43 and 44:

1.6 CHAPTER ONE Unitary Packaged Ai

- Page 45 and 46:

1.8 CHAPTER ONE Water System Centra

- Page 47 and 48:

1.10 CHAPTER ONE fire protection sy

- Page 49 and 50:

1.12 CHAPTER ONE Unitary Packaged S

- Page 51 and 52:

1.14 CHAPTER ONE in the residential

- Page 53 and 54:

1.16 CHAPTER ONE shipments were 750

- Page 55 and 56:

1.18 CHAPTER ONE properly equipped

- Page 57 and 58:

1.20 CHAPTER ONE Engineer’s Quali

- Page 59 and 60:

1.22 CHAPTER ONE Drawings Specifica

- Page 61 and 62:

1.24 CHAPTER ONE criteria or system

- Page 63 and 64:

1.26 CHAPTER ONE ● Equipment sele

- Page 65 and 66:

1.28 CHAPTER ONE Rowland, F. S., Th

- Page 67 and 68:

2.2 CHAPTER TWO The amount of water

- Page 69 and 70:

2.4 CHAPTER TWO Dalton’s law is b

- Page 71 and 72:

2.6 CHAPTER TWO Temperature Measure

- Page 73 and 74:

2.8 CHAPTER TWO Degree of Saturatio

- Page 75 and 76:

2.10 CHAPTER TWO Density where pat

- Page 77 and 78:

2.12 CHAPTER TWO Thermodynamic Wet-

- Page 79 and 80:

2.14 CHAPTER TWO The term T � T

- Page 81 and 82:

2.16 CHAPTER TWO 2.8 HUMIDITY MEASU

- Page 83 and 84:

2.18 CHAPTER TWO FIGURE 2.7 Ion-exc

- Page 85 and 86:

2.20 CHAPTER TWO The last digit for

- Page 87 and 88:

2.22 CHAPTER TWO Cooling and Dehumi

- Page 89 and 90:

2.24 CHAPTER TWO p ws � From Eq.

- Page 91 and 92:

2.26 CHAPTER TWO Aslam, S., Charmch

- Page 93 and 94:

3.2 CHAPTER THREE 3.1 BUILDING ENVE

- Page 95 and 96:

3.4 CHAPTER THREE Convective Heat T

- Page 97 and 98:

3.6 CHAPTER THREE Overall Heat Tran

- Page 99 and 100:

3.8 CHAPTER THREE Heat Capacity The

- Page 101 and 102:

3.10 CHAPTER THREE Coefficients for

- Page 103 and 104:

3.12 CHAPTER THREE Temperature also

- Page 105 and 106:

3.14 CHAPTER THREE FIGURE 3.3 Mass

- Page 107 and 108:

3.16 CHAPTER THREE Moisture Transfe

- Page 109 and 110:

3.18 CHAPTER THREE During summer, t

- Page 111 and 112:

3.20 CHAPTER THREE TABLE 3.3 Therma

- Page 113 and 114:

3.22 CHAPTER THREE 3.7 SOLAR ANGLES

- Page 115 and 116:

3.24 CHAPTER THREE ● Solar altitu

- Page 117 and 118:

3.26 CHAPTER THREE In Table 3.5, th

- Page 119 and 120:

3.28 CHAPTER THREE National Climati

- Page 121 and 122:

3.30 CHAPTER THREE silver coatings

- Page 123 and 124:

3.32 CHAPTER THREE 3.10 HEAT ADMITT

- Page 125 and 126:

3.34 CHAPTER THREE design condition

- Page 127 and 128:

3.36 CHAPTER THREE Shading Coeffici

- Page 129 and 130:

3.38 CHAPTER THREE 40° north latit

- Page 131 and 132:

3.40 CHAPTER THREE and fire protect

- Page 133 and 134:

3.42 CHAPTER THREE External Shading

- Page 135 and 136:

3.44 CHAPTER THREE FIGURE 3.16 Shad

- Page 137 and 138:

3.46 CHAPTER THREE 3.12 HEAT EXCHAN

- Page 139 and 140:

3.48 CHAPTER THREE Example 3.2. At

- Page 141 and 142:

3.50 CHAPTER THREE Fenestration, in

- Page 143 and 144:

3.52 CHAPTER THREE Donnelly, R. G.,

- Page 145 and 146:

4.2 CHAPTER FOUR 2. Indoor air qual

- Page 147 and 148:

4.4 CHAPTER FOUR 4.3 METABOLIC RATE

- Page 149 and 150:

4.6 CHAPTER FOUR When the air veloc

- Page 151 and 152:

4.8 CHAPTER FOUR calculated as TABL

- Page 153 and 154:

4.10 CHAPTER FOUR FIGURE 4.2 Mean v

- Page 155 and 156:

4.12 CHAPTER FOUR FIGURE 4.4 Dimens

- Page 157 and 158:

4.14 CHAPTER FOUR Effective Tempera

- Page 159 and 160:

FIGURE 4.5 Fanger’s comfort chart

- Page 161 and 162:

4.18 CHAPTER FOUR Dew-point tempera

- Page 163 and 164:

4.20 CHAPTER FOUR lower boundary in

- Page 165 and 166:

4.22 CHAPTER FOUR FIGURE 4.9 Relati

- Page 167 and 168:

4.24 CHAPTER FOUR levels are as fol

- Page 169 and 170:

4.26 CHAPTER FOUR In Eq. (4.24), 0.

- Page 171 and 172:

4.28 CHAPTER FOUR 1. Total particul

- Page 173 and 174:

4.30 CHAPTER FOUR Outdoor Air Requi

- Page 175 and 176:

4.32 CHAPTER FOUR 4.12 SOUND LEVEL

- Page 177 and 178:

4.34 CHAPTER FOUR Human Response an

- Page 179 and 180:

4.36 CHAPTER FOUR FIGURE 4.11 Room

- Page 181 and 182:

4.38 CHAPTER FOUR hazardous, contam

- Page 183 and 184:

4.40 TABLE 4.10 Climatic Conditions

- Page 185 and 186:

4.42 CHAPTER FOUR 3. Outdoor weathe

- Page 187 and 188:

CHAPTER 5 ENERGY MANAGEMENT AND CON

- Page 189 and 190:

The 1973 energy crisis greatly boos

- Page 191 and 192:

The later the building is construct

- Page 193 and 194:

Control Methods ENERGY MANAGEMENT A

- Page 195 and 196:

5.3 CONTROL MODES Two-Position Cont

- Page 197 and 198:

Floating Control Proportional Contr

- Page 199 and 200:

The set point is the desired value

- Page 201 and 202:

where K is the derivative gain. The

- Page 203 and 204:

ENERGY MANAGEMENT AND CONTROL SYSTE

- Page 205 and 206:

Pressure Sensors Flow Sensors ENERG

- Page 207 and 208:

An infrared occupancy sensor senses

- Page 209 and 210:

For a direct-acting pneumatic tempe

- Page 211 and 212:

attery backup. However, EEPROM cann

- Page 213 and 214:

Types of Control Valves to the elec

- Page 215 and 216:

Valve Selection ENERGY MANAGEMENT A

- Page 217 and 218:

design water flow rate V˙ , gpm (L

- Page 219 and 220:

The movement of the split damper fr

- Page 221 and 222:

damper is then fully opened. If the

- Page 223 and 224:

Damper Selection Damper Sizing wher

- Page 225 and 226:

BAC net SC BAC net UC UC UC UC SC A

- Page 227 and 228:

Future Development The development

- Page 229 and 230:

Network Layer Conformance Class, Fu

- Page 231 and 232:

5.10 CONTROL LOGIC AND ARTIFICIAL I

- Page 233 and 234:

Fuzzy Logic Controller. An FLC cons

- Page 235 and 236:

give a printout. A friendly dialog

- Page 237 and 238:

Artificial Neural Networks ENERGY M

- Page 239 and 240:

3. Evaluate the error � between t

- Page 241 and 242:

Graphical Programming for Mechanica

- Page 243 and 244:

System Capacity changes during off-

- Page 245 and 246:

Generic Controls ENERGY MANAGEMENT

- Page 247 and 248:

● Central plant control Multiple-

- Page 249 and 250:

The diagnostician used color coding

- Page 251 and 252:

Discharge air temperature T dis,

- Page 253 and 254:

REFERENCES ENERGY MANAGEMENT AND CO

- Page 255 and 256:

ENERGY MANAGEMENT AND CONTROL SYSTE

- Page 257 and 258:

6.2 CHAPTER SIX 6.1 SPACE LOAD CHAR

- Page 259 and 260:

6.4 CHAPTER SIX FIGURE 6.2 Solar he

- Page 261 and 262:

6.6 CHAPTER SIX Influence of Stored

- Page 263 and 264:

6.8 CHAPTER SIX leaving the coil, s

- Page 265 and 266:

6.10 CHAPTER SIX the maximum sum of

- Page 267 and 268:

6.12 CHAPTER SIX adoption of person

- Page 269 and 270:

6.14 CHAPTER SIX Characteristics of

- Page 271 and 272:

6.16 CHAPTER SIX where T sol, a �

- Page 273 and 274:

6.18 CHAPTER SIX Space latent heat

- Page 275 and 276:

6.20 CHAPTER SIX FIGURE 6.7 Relatio

- Page 277 and 278:

6.22 TABLE 6.2 CLTD for Calculating

- Page 279 and 280:

6.24 CHAPTER SIX Infiltration Infil

- Page 281 and 282:

6.26 CHAPTER SIX nighttime in summe

- Page 283 and 284:

6.28 CHAPTER SIX ● Outer surface

- Page 285 and 286:

6.30 TABLE 6.6 July Solar Cooling L

- Page 287 and 288:

6.32 CHAPTER SIX From Eqs. (6.19a)

- Page 289 and 290:

6.34 CHAPTER SIX thickness of the d

- Page 291 and 292:

6.36 CHAPTER SIX Simplifying Assump

- Page 293 and 294:

6.38 CHAPTER SIX where hci � conv

- Page 295 and 296:

6.40 CHAPTER SIX Adjacent Unheated

- Page 297 and 298:

6.42 CHAPTER SIX the next morning b

- Page 299 and 300:

6.44 CHAPTER SIX Trace 600 Input—

- Page 301 and 302:

6.46 CHAPTER SIX ● For the calcul

- Page 303 and 304:

6.48 CHAPTER SIX Area of perimeter

- Page 305 and 306:

6.50 CHAPTER SIX Komor, P., Space C

- Page 307 and 308:

7.2 CHAPTER SEVEN 7.1 FUNDAMENTALS

- Page 309 and 310:

7.4 CHAPTER SEVEN Open systems need

- Page 311 and 312:

7.6 CHAPTER SEVEN FIGURE 7.2 Fricti

- Page 313 and 314:

7.8 TABLE 7.1 Dimensions of Commonl

- Page 315 and 316:

TABLE 7.2 Dimensions of Copper Tube

- Page 317 and 318:

7.12 CHAPTER SEVEN Pipe Joints Copp

- Page 319 and 320:

7.14 CHAPTER SEVEN also be consider

- Page 321 and 322:

7.16 CHAPTER SEVEN Insulation expos

- Page 323 and 324:

7.18 CHAPTER SEVEN Valve Materials

- Page 325 and 326:

7.20 CHAPTER SEVEN Open Expansion T

- Page 327 and 328:

7.22 CHAPTER SEVEN FIGURE 7.8 Close

- Page 329 and 330:

7.24 CHAPTER SEVEN Penalties due to

- Page 331 and 332:

7.26 CHAPTER SEVEN TABLE 7.7 Analys

- Page 333 and 334:

7.28 CHAPTER SEVEN Changeover Two P

- Page 335 and 336:

7.30 CHAPTER SEVEN a semiautomatic

- Page 337 and 338:

7.32 CHAPTER SEVEN Performance Curv

- Page 339 and 340:

7.34 CHAPTER SEVEN remove. In most

- Page 341 and 342:

7.36 CHAPTER SEVEN FIGURE 7.15 Comb

- Page 343 and 344:

7.38 CHAPTER SEVEN The wire-to-wate

- Page 345 and 346:

7.40 CHAPTER SEVEN Variable Flow fo

- Page 347 and 348:

7.42 CHAPTER SEVEN Chiller VSD 2 VS

- Page 349 and 350:

7.44 5 2 6 Plant hot water pump Boi

- Page 351 and 352:

7.46 CHAPTER SEVEN Sequence of Oper

- Page 353 and 354:

7.48 CHAPTER SEVEN FIGURE 7.20 (Con

- Page 355 and 356:

7.50 CHAPTER SEVEN Use of Balancing

- Page 357 and 358:

7.52 CHAPTER SEVEN 2. For Qcs/Qcs,d

- Page 359 and 360:

7.54 CHAPTER SEVEN The following ar

- Page 361 and 362:

7.56 CHAPTER SEVEN loops. However,

- Page 363 and 364:

7.58 CHAPTER SEVEN DDC system contr

- Page 365 and 366:

7.60 CHAPTER SEVEN REFERENCES Input

- Page 367 and 368:

CHAPTER 8 HEATING SYSTEMS, FURNACES

- Page 369 and 370:

8.2 WARM AIR FURNACES Types of Warm

- Page 371 and 372:

Heat exchanger Warm air supply plen

- Page 373 and 374:

Saving Energy ● Annual fuel utili

- Page 375 and 376:

Nighttime Setback. ASHRAE research

- Page 377 and 378:

HEATING SYSTEMS, FURNACES, AND BOIL

- Page 379 and 380:

Gas and Oil Burners When natural ga

- Page 381 and 382:

Modern packaged boilers often inclu

- Page 383 and 384:

Electric Hot Water Boilers elements

- Page 385 and 386:

where volume flow rate of supply ai

- Page 387 and 388:

Thermal Stratification divided into

- Page 389 and 390:

15°F (8.3°C) is usually used. The

- Page 391 and 392:

Design Considerations FIGURE 8.8 Ba

- Page 393 and 394:

finned tube is 1190 Btu/h (350 W).

- Page 395 and 396:

Heating flux q u, Btu/h•ft 2 Floo

- Page 397 and 398:

● Pulse-width-modulated zone cont

- Page 399 and 400:

Design and Layout HEATING SYSTEMS,

- Page 401 and 402:

REFERENCES HEATING SYSTEMS, FURNACE

- Page 403 and 404:

CHAPTER 9 REFRIGERANTS, REFRIGERATI

- Page 405 and 406:

9.2 REFRIGERANTS Refrigerants, Cool

- Page 407 and 408:

9.3 PROPERTIES AND CHARACTERISTICS

- Page 409 and 410:

● Halide torch. This method is si

- Page 411 and 412:

9.9 Specific volume of Power Critic

- Page 413 and 414:

Action and Measures REFRIGERANTS, R

- Page 415 and 416:

Because of the worldwide effort to

- Page 417 and 418:

Zeotropic HFC HFC-410A is a blend o

- Page 419 and 420:

Refrigeration Cycles Unit of Refrig

- Page 421 and 422:

the diagram and temperature T, °R,

- Page 423 and 424:

The heat extracted from the source

- Page 425 and 426:

REFRIGERANTS, REFRIGERATION CYCLES,

- Page 427 and 428:

REFRIGERANTS, REFRIGERATION CYCLES,

- Page 429 and 430:

REFRIGERANTS, REFRIGERATION CYCLES,

- Page 431 and 432:

With subcooling, Savings in electri

- Page 433 and 434:

calculated as where p con � conde

- Page 435 and 436:

Coefficient of Performance REFRIGER

- Page 437 and 438:

Then, from Eq. (9.33), the total wo

- Page 439 and 440:

x 1 at interstage pressure p i1 can

- Page 441 and 442:

REFRIGERANTS, REFRIGERATION CYCLES,

- Page 443 and 444:

REFRIGERANTS, REFRIGERATION CYCLES,

- Page 445 and 446:

REFRIGERANTS, REFRIGERATION CYCLES,

- Page 447 and 448:

From Eq. (9.22), the enthalpy diffe

- Page 449 and 450:

FIGURE 9.13 (Continued) where p 1,

- Page 451 and 452:

If �c, �t, TR1� , TR3, and pr

- Page 453 and 454:

Recent Developments ASHRAE Standard

- Page 455 and 456:

The only type of non-positive displ

- Page 457 and 458:

Energy Use Index In Eq. (9.71), m˙

- Page 459 and 460:

For institutional or health care oc

- Page 461 and 462:

Storage of Refrigerants REFERENCES

- Page 463 and 464:

CHAPTER 10 REFRIGERATION SYSTEMS: C

- Page 465 and 466:

● Shell-and-tube liquid cooler wi

- Page 467 and 468:

at an oil concentration of 3 percen

- Page 469 and 470:

or h al � h ae � �(h ae � h

- Page 471 and 472:

FIGURE 10.3 Control of DX coils at

- Page 473 and 474:

Example 10.1. A DX coil in a packag

- Page 475 and 476:

REFRIGERATION SYSTEMS: COMPONENTS 1

- Page 477 and 478:

where U dirty, U clean � overall

- Page 479 and 480:

Temperature difference T ee � T e

- Page 481 and 482:

FIGURE 10.7 (Continued) (b) Schemat

- Page 483 and 484:

Total Heat Rejection Compared with

- Page 485 and 486: FIGURE 10.9 Double-tube condenser.

- Page 487 and 488: It is important to recognize that t

- Page 489 and 490: REFRIGERATION SYSTEMS: COMPONENTS 1

- Page 491 and 492: A refrigeration system with a lower

- Page 493 and 494: REFRIGERATION SYSTEMS: COMPONENTS 1

- Page 495 and 496: Selection and Installation REFRIGER

- Page 497 and 498: Counterflow Forced-Draft Cooling To

- Page 499 and 500: air film that surrounds the condens

- Page 501 and 502: By using the numerical integration

- Page 503 and 504: Tower Coefficient and Water-Air Rat

- Page 505 and 506: Construction Materials cellular fil

- Page 507 and 508: (T w2 � T w1)/(h s � h a), or t

- Page 509 and 510: Blowdown Legionnaires’ Disease va

- Page 511 and 512: REFRIGERATION SYSTEMS: COMPONENTS 1

- Page 513 and 514: The rated conditions of air-cooled

- Page 515 and 516: The corresponding saturated tempera

- Page 517 and 518: Electric Expansion Valves slugs may

- Page 519 and 520: Capillary Tube FIGURE 10.21 Float v

- Page 521 and 522: REFRIGERATION SYSTEMS: COMPONENTS 1

- Page 523 and 524: 11.2 CHAPTER ELEVEN 11.1 RECIPROCAT

- Page 525 and 526: 11.4 CHAPTER ELEVEN refrigerants. A

- Page 527 and 528: 11.6 FIGURE 11.5 Schematic reciproc

- Page 529 and 530: 11.8 CHAPTER ELEVEN Accessories sys

- Page 531 and 532: 11.10 CHAPTER ELEVEN into the inner

- Page 533 and 534: 11.12 CHAPTER ELEVEN FIGURE 11.8 Se

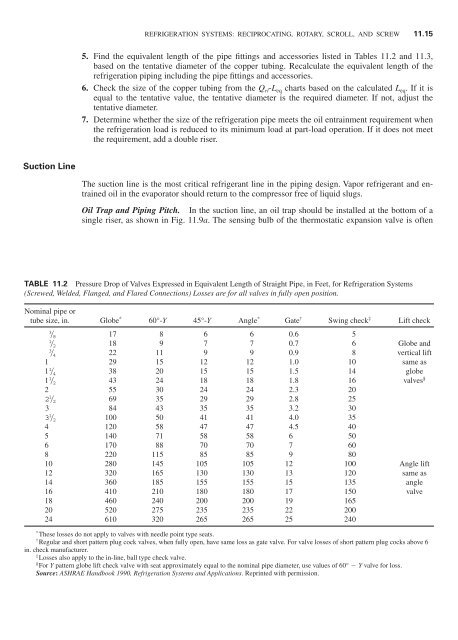

- Page 535: 11.14 CHAPTER ELEVEN Size of Copper

- Page 539 and 540: 11.18 CHAPTER ELEVEN FIGURE 11.10 S

- Page 541 and 542: 11.20 CHAPTER ELEVEN 5. The minimum

- Page 543 and 544: 11.22 CHAPTER ELEVEN If a receiver

- Page 545 and 546: 11.24 CHAPTER ELEVEN 11.5 CAPACITY

- Page 547 and 548: 11.26 CHAPTER ELEVEN Safety Control

- Page 549 and 550: 11.28 CHAPTER ELEVEN FIGURE 11.16 L

- Page 551 and 552: 11.30 CHAPTER ELEVEN Refrigeration

- Page 553 and 554: 11.32 CHAPTER ELEVEN Performance of

- Page 555 and 556: 11.34 CHAPTER ELEVEN 11.7 SYSTEM BA

- Page 557 and 558: 11.36 CHAPTER ELEVEN compression ra

- Page 559 and 560: 11.38 CHAPTER ELEVEN is superheated

- Page 561 and 562: 11.40 CHAPTER ELEVEN in Fig. 11.22,

- Page 563 and 564: 11.42 CHAPTER ELEVEN (2048 kPa abs.

- Page 565 and 566: 11.44 CHAPTER ELEVEN Scroll Compres

- Page 567 and 568: 11.46 CHAPTER ELEVEN Compressor Per

- Page 569 and 570: 11.48 CHAPTER ELEVEN System Charact

- Page 571 and 572: 11.50 CHAPTER ELEVEN are specified

- Page 573 and 574: 11.52 CHAPTER ELEVEN FIGURE 11.29 T

- Page 575 and 576: 11.54 CHAPTER ELEVEN Variable Volum

- Page 577 and 578: 11.56 CHAPTER ELEVEN REFERENCES ASH

- Page 579 and 580: CHAPTER 12 HEAT PUMPS, HEAT RECOVER

- Page 581 and 582: where h 2� � enthalpy of hot ga

- Page 583 and 584: climates, cold supply air may be re

- Page 585 and 586: FIGURE 12.3 (Continued) HEAT PUMPS,

- Page 587 and 588:

Operating Modes System Performance

- Page 589 and 590:

load. When the outdoor temperature

- Page 591 and 592:

Controls Capacity and Selection HEA

- Page 593 and 594:

FIGURE 12.5 A typical groundwater h

- Page 595 and 596:

HEAT PUMPS, HEAT RECOVERY, GAS COOL

- Page 597 and 598:

A vertical ground coil is buried fr

- Page 599 and 600:

Exhaust airstream Runaround Coil Lo

- Page 601 and 602:

HEAT PUMPS, HEAT RECOVERY, GAS COOL

- Page 603 and 604:

Comparison between Various Air-to-A

- Page 605 and 606:

Gas-Engine Chiller Gas Engines HEAT

- Page 607 and 608:

When the engine jacket water is rou

- Page 609 and 610:

CHAPTER 13 REFRIGERATION SYSTEMS: C

- Page 611 and 612:

Compressor REFRIGERATION SYSTEMS: C

- Page 613 and 614:

Purge Unit FIGURE 13.3 Orifice plat

- Page 615 and 616:

Types of Centrifugal Chiller match

- Page 617 and 618:

For water-cooled centrifugal chille

- Page 619 and 620:

FIGURE 13.5 (Continued ) REFRIGERAT

- Page 621 and 622:

(5.6 to 6.7°C) in temperature diff

- Page 623 and 624:

● The maintenance cost can be red

- Page 625 and 626:

FIGURE 13.10 (Continued ) where Q r

- Page 627 and 628:

13.6 CAPACITY CONTROL OF CENTRIFUGA

- Page 629 and 630:

Comparison between Inlet Vanes and

- Page 631 and 632:

Condenser Water Temperature Control

- Page 633 and 634:

7. After the oil pressure has been

- Page 635 and 636:

The log-mean temperature difference

- Page 637 and 638:

Therefore, from Eq. (13.12) the eva

- Page 639 and 640:

The actual percentage of design pow

- Page 641 and 642:

water enters the condenser T en, c

- Page 643 and 644:

Chiller Minimum Performance Design

- Page 645 and 646:

REFRIGERATION SYSTEMS: CENTRIFUGAL

- Page 647 and 648:

14.2 CHAPTER FOURTEEN Historical De

- Page 649 and 650:

14.4 CHAPTER FOURTEEN Equilibrium C

- Page 651 and 652:

14.6 CHAPTER FOURTEEN If an aqueous

- Page 653 and 654:

14.8 CHAPTER FOURTEEN Air Purge Uni

- Page 655 and 656:

14.10 CHAPTER FOURTEEN 10 5 20 40 1

- Page 657 and 658:

14.12 CHAPTER FOURTEEN Also, Therma

- Page 659 and 660:

14.14 CHAPTER FOURTEEN Coefficient

- Page 661 and 662:

14.16 CHAPTER FOURTEEN From the psy

- Page 663 and 664:

14.18 CHAPTER FOURTEEN bypass recir

- Page 665 and 666:

14.20 CHAPTER FOURTEEN Corrosion Co

- Page 667 and 668:

14.22 CHAPTER FOURTEEN Actual Perfo

- Page 669 and 670:

14.24 CHAPTER FOURTEEN absorber and

- Page 671 and 672:

14.26 CHAPTER FOURTEEN Coefficient

- Page 673 and 674:

CHAPTER 15 AIR SYSTEMS: COMPONENTS

- Page 675 and 676:

FIGURE 15.1 Types of fans: (a) cent

- Page 677 and 678:

The fan power input on the fan shaf

- Page 679 and 680:

where �p t,s � fan total pressu

- Page 681 and 682:

The total pressure developed is AIR

- Page 683 and 684:

Forward-Curved Fans AIR SYSTEMS: CO

- Page 685 and 686:

AIR SYSTEMS: COMPONENTS—FANS, COI

- Page 687 and 688:

AIR SYSTEMS: COMPONENTS—FANS, COI

- Page 689 and 690:

AIR SYSTEMS: COMPONENTS—FANS, COI

- Page 691 and 692:

AIR SYSTEMS: COMPONENTS—FANS, COI

- Page 693 and 694:

Inlet Vanes Modulation AIR SYSTEMS:

- Page 695 and 696:

Inlet Cone Modulation AIR SYSTEMS:

- Page 697 and 698:

the smooth airflow suddenly breaks

- Page 699 and 700:

High-Temperature Fans AIR SYSTEMS:

- Page 701 and 702:

FIGURE 15.24 Direction of rotation

- Page 703 and 704:

octave bands for axial fans are far

- Page 705 and 706:

Types of Coils Fins AIR SYSTEMS: CO

- Page 707 and 708:

AIR SYSTEMS: COMPONENTS—FANS, COI

- Page 709 and 710:

Contact Conductance AIR SYSTEMS: CO

- Page 711 and 712:

Water Circuits Contact conductance

- Page 713 and 714:

If the thermal resistance of copper

- Page 715 and 716:

AIR SYSTEMS: COMPONENTS—FANS, COI

- Page 717 and 718:

Coil Construction Parameters AIR SY

- Page 719 and 720:

And from Eq. (15.34), Assume � f

- Page 721 and 722:

Dry Part airstream and water stream

- Page 723 and 724:

FIGURE 15.32 Psychrometric analysis

- Page 725 and 726:

cooling and dehumidifying capacity

- Page 727 and 728:

From Eq. (15.27), Then the outer su

- Page 729 and 730:

Coil Cleanliness Drain and Isolatin

- Page 731 and 732:

AIR SYSTEMS: COMPONENTS—FANS, COI

- Page 733 and 734:

particles may range from � 1�m

- Page 735 and 736:

AIR SYSTEMS: COMPONENTS—FANS, COI

- Page 737 and 738:

15.14 AIR FILTERS Filtration Mechan

- Page 739 and 740:

● Most low-efficiency filters hav

- Page 741 and 742:

15.15 ELECTRONIC AIR CLEANERS AIR S

- Page 743 and 744:

usually decreases the adsorption ca

- Page 745 and 746:

FIGURE 15.41 Humidifying load for a

- Page 747 and 748:

Heating Element Humidifiers AIR SYS

- Page 749 and 750:

Ultrasonic Humidifiers An ultrasoni

- Page 751 and 752:

15.21 AIR WASHERS The air washer wa

- Page 753 and 754:

Bypass Control For a cooling and de

- Page 755 and 756:

industrial manufacturing processes

- Page 757 and 758:

REFERENCES AIR SYSTEMS: COMPONENTS

- Page 759 and 760:

CHAPTER 16 AIR SYSTEMS: EQUIPMENT

- Page 761 and 762:

FIGURE 16.1 Type of air-handling un

- Page 763 and 764:

Coils Filters Humidifiers AIR SYSTE

- Page 765 and 766:

AIR SYSTEMS: EQUIPMENT—AIR-HANDLI

- Page 767 and 768:

15.10, the cooling coil face veloci

- Page 769 and 770:

16.11 TABLE 16.2 Volume Flow and Fa

- Page 771 and 772:

AIR SYSTEMS: EQUIPMENT—AIR-HANDLI

- Page 773 and 774:

Indoor Packaged Units AIR SYSTEMS:

- Page 775 and 776:

Reciprocating and scroll compressor

- Page 777 and 778:

Minimum Performance 9. Compressor l

- Page 779 and 780:

16.21 TABLE 16.4 Supply Fan Perform

- Page 781 and 782:

There will be no carryover of conde

- Page 783 and 784:

AIR SYSTEMS: EQUIPMENT—AIR-HANDLI

- Page 785 and 786:

FIGURE 16.9 Interior core fan room:

- Page 787 and 788:

CHAPTER 17 AIR SYSTEMS: AIR DUCT DE

- Page 789 and 790:

p� 1 � � 1v 1 2 (17.4) If bot

- Page 791 and 792:

Stack Effect where � � air dens

- Page 793 and 794:

Velocity Distribution Equation of C

- Page 795 and 796:

FIGURE 17.3 Pressure characteristic

- Page 797 and 798:

where Psy � each air system total

- Page 799 and 800:

Rectangular Ducts AIR SYSTEMS: AIR

- Page 801 and 802:

17.15 TABLE 17.2 Rectangular Ferrou

- Page 803 and 804:

TABLE 17.4 Round Ferrous Metal Duct

- Page 805 and 806:

17.4 DUCT HEAT GAIN, HEAT LOSS, AND

- Page 807 and 808:

Temperature Rise Curves If the temp

- Page 809 and 810:

In an ideal smooth tube or duct, th

- Page 811 and 812:

loss per unit length �p f, in in.

- Page 813 and 814:

Circular Equivalents Example 17.1.

- Page 815 and 816:

17.29 42 15.6 17.1 18.5 19.9 21.1 2

- Page 817 and 818:

For galvanized steel flat oval duct

- Page 819 and 820:

AIR SYSTEMS: AIR DUCT DESIGN 17.33

- Page 821 and 822:

FIGURE 17.12 Round and flat oval te

- Page 823 and 824:

FIGURE 17.14 Openings mounted on a

- Page 825 and 826:

FIGURE 17.16 Total pressure loss

- Page 827 and 828:

FIGURE 17.17 Combination of flow re

- Page 829 and 830:

Fig. 17.19a, are given as and (17.6

- Page 831 and 832:

● An optimal duct system layout w

- Page 833 and 834:

● From node 1, the total pressure

- Page 835 and 836:

TABLE 17.10 Duct Leakage Classifica

- Page 837 and 838:

each fire damper. Many regulatory a

- Page 839 and 840:

The designer then compares various

- Page 841 and 842:

T Method planes 1 and 2, and the vo

- Page 843 and 844:

h, or in I-P units For SI units, FI

- Page 845 and 846:

When the total pressure loss of the

- Page 847 and 848:

TABLE 17.11 Local Loss Coefficients

- Page 849 and 850:

Return or Exhaust Duct Systems AIR

- Page 851 and 852:

and the sized diameter 0.0147 � 2

- Page 853 and 854:

FIGURE 17.25 Rectangular supply duc

- Page 855 and 856:

If the height of the rectangular du

- Page 857 and 858:

FIGURE 17.28 A return duct system w

- Page 859 and 860:

Design Interface AIR SYSTEMS: AIR D

- Page 861 and 862:

vacuum used in duct cleaning is oft

- Page 863 and 864:

accurate measurement, an inclined m

- Page 865 and 866:

AIR SYSTEMS: AIR DUCT DESIGN 17.79

- Page 867 and 868:

18.2 CHAPTER EIGHTEEN Design Consid

- Page 869 and 870:

18.4 CHAPTER EIGHTEEN cooling load

- Page 871 and 872:

18.6 CHAPTER EIGHTEEN FIGURE 18.2 F

- Page 873 and 874:

18.8 CHAPTER EIGHTEEN Confined Air

- Page 875 and 876:

18.10 CHAPTER EIGHTEEN Free Nonisot

- Page 877 and 878:

18.12 CHAPTER EIGHTEEN Ceiling Diff

- Page 879 and 880:

18.14 CHAPTER EIGHTEEN Slot Diffuse

- Page 881 and 882:

18.16 CHAPTER EIGHTEEN TABLE 18.1 P

- Page 883 and 884:

18.18 CHAPTER EIGHTEEN FIGURE 18.12

- Page 885 and 886:

18.20 CHAPTER EIGHTEEN 18.4 MIXING

- Page 887 and 888:

18.22 CHAPTER EIGHTEEN FIGURE 18.15

- Page 889 and 890:

18.24 CHAPTER EIGHTEEN FIGURE 18.17

- Page 891 and 892:

18.26 CHAPTER EIGHTEEN FIGURE 18.19

- Page 893 and 894:

18.28 CHAPTER EIGHTEEN ● The loca

- Page 895 and 896:

18.30 CHAPTER EIGHTEEN ● The aver

- Page 897 and 898:

18.32 CHAPTER EIGHTEEN ● Cost. In

- Page 899 and 900:

18.34 CHAPTER EIGHTEEN ● A termin

- Page 901 and 902:

18.36 CHAPTER EIGHTEEN FIGURE 18.22

- Page 903 and 904:

18.38 CHAPTER EIGHTEEN The return s

- Page 905 and 906:

18.40 CHAPTER EIGHTEEN Ventilating

- Page 907 and 908:

18.42 CHAPTER EIGHTEEN 18.8 STRATIF

- Page 909 and 910:

18.44 CHAPTER EIGHTEEN 18.9 PROJECT

- Page 911 and 912:

18.46 CHAPTER EIGHTEEN Target Veloc

- Page 913 and 914:

18.48 CHAPTER EIGHTEEN Application

- Page 915 and 916:

18.50 CHAPTER EIGHTEEN Heat Unneutr

- Page 917 and 918:

18.52 CHAPTER EIGHTEEN CFD Becomes

- Page 919 and 920:

18.54 CHAPTER EIGHTEEN Conducting C

- Page 921 and 922:

18.56 CHAPTER EIGHTEEN Wendes, H.,

- Page 923 and 924:

19.2 CHAPTER NINETEEN Sound Paths T

- Page 925 and 926:

19.4 CHAPTER NINETEEN 9. Check this

- Page 927 and 928:

19.6 CHAPTER NINETEEN Branch ducts

- Page 929 and 930:

19.8 CHAPTER NINETEEN TABLE 19.3 So

- Page 931 and 932:

19.10 CHAPTER NINETEEN End Reflecti

- Page 933 and 934:

19.12 CHAPTER NINETEEN 19.4 SILENCE

- Page 935 and 936:

19.14 CHAPTER NINETEEN facing. A so

- Page 937 and 938:

19.16 CHAPTER NINETEEN Active Silen

- Page 939 and 940:

19.18 CHAPTER NINETEEN Recommendati

- Page 941 and 942:

19.20 CHAPTER NINETEEN FIGURE 19.6

- Page 943 and 944:

19.22 CHAPTER NINETEEN TABLE 19.11

- Page 945 and 946:

19.24 CHAPTER NINETEEN Array of Cei

- Page 947 and 948:

19.26 CHAPTER NINETEEN Environmenta

- Page 949 and 950:

19.28 CHAPTER NINETEEN Octave band

- Page 951 and 952:

19.30 CHAPTER NINETEEN Sound Source

- Page 953 and 954:

19.32 CHAPTER NINETEEN Structure-Bo

- Page 955 and 956:

CHAPTER 20 AIR SYSTEMS: BASICS AND

- Page 957 and 958:

Air Distribution Systems Ventilatio

- Page 959 and 960:

20.2 BUILDING LEAKAGE AREA AND BUIL

- Page 961 and 962:

20.3 SPACE PRESSURIZATION Space Pre

- Page 963 and 964:

doors and windows are closed. When

- Page 965 and 966:

Wind speed from a meteorological st

- Page 967 and 968:

In Eq. (20.8), m˙ inf indicates th

- Page 969 and 970:

System Operating Point FIGURE 20.4

- Page 971 and 972:

20.6 SYSTEM EFFECT ● Condition 1.

- Page 973 and 974:

Inlet System Effect Loss fan inlet

- Page 975 and 976:

FIGURE 20.7 Outlet system effect: (

- Page 977 and 978:

For a SWSI centrifugal fan with A b

- Page 979 and 980:

Two Fan-Duct Systems Connected in S

- Page 981 and 982:

volume flow and fan total pressure.

- Page 983 and 984:

FIGURE 20.12 Two parallel fan-duct

- Page 985 and 986:

Similarly, the residual pressure of

- Page 987 and 988:

Modulation of Fan-Duct Systems AIR

- Page 989 and 990:

FIGURE 20.14 (Continued) AIR SYSTEM

- Page 991 and 992:

Plot the fan performance curve Ft a

- Page 993 and 994:

20.9 CLASSIFICATION OF AIR SYSTEMS

- Page 995 and 996:

To save energy, most AHU and PU man

- Page 997 and 998:

where ws,wr � humidity ratio at t

- Page 999 and 1000:

exchanger is called the sensible co

- Page 1001 and 1002:

compressed air, or ultrasonic force

- Page 1003 and 1004:

AIR SYSTEMS: BASICS AND CONSTANT-VO

- Page 1005 and 1006:

FIGURE 20.21 Adiabatic mixing and b

- Page 1007 and 1008:

and the heating coil load is 20.16

- Page 1009 and 1010:

Cooling mode operation in summer co

- Page 1011 and 1012:

ecirculating air m is usually lower

- Page 1013 and 1014:

● Outdoor damper activates with s

- Page 1015 and 1016:

3. To provide a desirable air veloc

- Page 1017 and 1018:

Air Conditioning Rules Graphical Me

- Page 1019 and 1020:

FIGURE 20.25 Effect of sensible hea

- Page 1021 and 1022:

2. Because the air temperature at t

- Page 1023 and 1024:

At a temperature of 72°F (22.2°C)

- Page 1025 and 1026:

Because w m � w s, Therefore, Fro

- Page 1027 and 1028:

Part-Load Operation 7. Draw a verti

- Page 1029 and 1030:

Reheating is a simple and effective

- Page 1031 and 1032:

Operating Parameters and Calculatio

- Page 1033 and 1034:

REFERENCES AIR SYSTEMS: BASICS AND

- Page 1035 and 1036:

21.2 CHAPTER TWENTY-ONE 21.1 SYSTEM

- Page 1037 and 1038:

FIGURE 21.1 A single-zone VAV syste

- Page 1039 and 1040:

21.6 CHAPTER TWENTY-ONE FIGURE 21.2

- Page 1041 and 1042:

21.8 CHAPTER TWENTY-ONE Region IV:

- Page 1043 and 1044:

21.10 CHAPTER TWENTY-ONE dry-bulb e

- Page 1045 and 1046:

21.12 CHAPTER TWENTY-ONE Consider a

- Page 1047 and 1048:

21.14 CHAPTER TWENTY-ONE ● The ou

- Page 1049 and 1050:

21.16 CHAPTER TWENTY-ONE outdoor ve

- Page 1051 and 1052:

21.18 CHAPTER TWENTY-ONE 7. When T

- Page 1053 and 1054:

21.20 CHAPTER TWENTY-ONE VAV Reheat

- Page 1055 and 1056:

21.22 CHAPTER TWENTY-ONE FIGURE 21.

- Page 1057 and 1058:

21.24 CHAPTER TWENTY-ONE FIGURE 21.

- Page 1059 and 1060:

21.26 CHAPTER TWENTY-ONE In dead-ba

- Page 1061 and 1062:

21.28 CHAPTER TWENTY-ONE For the pe

- Page 1063 and 1064:

21.30 CHAPTER TWENTY-ONE calculated

- Page 1065 and 1066:

21.32 CHAPTER TWENTY-ONE For the wi

- Page 1067 and 1068:

21.34

- Page 1069 and 1070:

21.36 CHAPTER TWENTY-ONE Number of

- Page 1071 and 1072:

21.38 CHAPTER TWENTY-ONE Mixing Mod

- Page 1073 and 1074:

21.40 CHAPTER TWENTY-ONE ● Modula

- Page 1075 and 1076:

21.42 CHAPTER TWENTY-ONE where Q rs

- Page 1077 and 1078:

21.44 CHAPTER TWENTY-ONE From Eq. (

- Page 1079 and 1080:

FIGURE 21.13 (Continued) 21.46

- Page 1081 and 1082:

21.48 CHAPTER TWENTY-ONE Fan-Powere

- Page 1083 and 1084:

21.50 CHAPTER TWENTY-ONE The drawba

- Page 1085 and 1086:

21.52 CHAPTER TWENTY-ONE Zone Contr

- Page 1087 and 1088:

21.54 CHAPTER TWENTY-ONE Percentage

- Page 1089 and 1090:

21.56 CHAPTER TWENTY-ONE ● During

- Page 1091 and 1092:

21.58 CHAPTER TWENTY-ONE Wendes, H.

- Page 1093 and 1094:

22.2 CHAPTER TWENTY-TWO 22.1 RETURN

- Page 1095 and 1096:

22.4 CHAPTER TWENTY-TWO 22.2 FAN CO

- Page 1097 and 1098:

22.6 CHAPTER TWENTY-TWO Recirculati

- Page 1099 and 1100:

22.8 CHAPTER TWENTY-TWO flow rate o

- Page 1101 and 1102:

22.10 CHAPTER TWENTY-TWO FIGURE 22.

- Page 1103 and 1104:

22.12 CHAPTER TWENTY-TWO The system

- Page 1105 and 1106:

22.14 CHAPTER TWENTY-TWO to balance

- Page 1107 and 1108:

22.16 CHAPTER TWENTY-TWO The fixed

- Page 1109 and 1110:

22.18 CHAPTER TWENTY-TWO air is ext

- Page 1111 and 1112:

22.20 CHAPTER TWENTY-TWO Air Econom

- Page 1113 and 1114:

22.22 CHAPTER TWENTY-TWO (2) The re

- Page 1115 and 1116:

22.24 CHAPTER TWENTY-TWO FIGURE 22.

- Page 1117 and 1118:

22.26 CHAPTER TWENTY-TWO FIGURE 22.

- Page 1119 and 1120:

22.28 CHAPTER TWENTY-TWO ● The as

- Page 1121 and 1122:

22.30 CHAPTER TWENTY-TWO FIGURE 22.

- Page 1123 and 1124:

22.32 CHAPTER TWENTY-TWO Design Con

- Page 1125 and 1126:

22.34 CHAPTER TWENTY-TWO �a � a

- Page 1127 and 1128:

22.36 CHAPTER TWENTY-TWO The pressu

- Page 1129 and 1130:

22.38 CHAPTER TWENTY-TWO REFERENCES

- Page 1131 and 1132:

CHAPTER 23 AIR SYSTEMS: MINIMUM VEN

- Page 1133 and 1134:

ASHRAE Standard 62-1999 control, a

- Page 1135 and 1136:

The system outdoor air volume flow

- Page 1137 and 1138:

CO 2 Sensor or Mixed-Gases Sensor L

- Page 1139 and 1140:

supplied to a control zone in a VAV

- Page 1141 and 1142:

Economizer damper Exhaust damper Mi

- Page 1143 and 1144:

AIR SYSTEMS: MINIMUM VENTILATION AN

- Page 1145 and 1146:

● The maximum supply volume flow

- Page 1147 and 1148:

where m˙ ex,r, m˙ eu � mass flo

- Page 1149 and 1150:

System Description AIR SYSTEMS: MIN

- Page 1151 and 1152:

AIR SYSTEMS: MINIMUM VENTILATION AN

- Page 1153 and 1154:

● It lowers the duct heat gain or

- Page 1155 and 1156:

AIR SYSTEMS: MINIMUM VENTILATION AN

- Page 1157 and 1158:

Steam Humidifier Control Dew Point

- Page 1159 and 1160:

consumption than proportional contr

- Page 1161 and 1162:

AIR SYSTEMS: MINIMUM VENTILATION AN

- Page 1163 and 1164:

AIR SYSTEMS: MINIMUM VENTILATION AN

- Page 1165 and 1166:

REFERENCES AIR SYSTEMS: MINIMUM VEN

- Page 1167 and 1168:

24.1 IAQ PROBLEMS CHAPTER 24 IMPROV

- Page 1169 and 1170:

air economizer cycle and mixed air

- Page 1171 and 1172:

Sundell (1996) noted that many stud

- Page 1173 and 1174:

Service Life of Air Filters Filter

- Page 1175 and 1176:

● To eliminate or to reduce indoo

- Page 1177 and 1178:

Chemisorption Fig. 24.1, the sharp

- Page 1179 and 1180:

and final filter in air systems wit

- Page 1181 and 1182:

REFERENCES IMPROVING INDOOR AIR QUA

- Page 1183 and 1184:

25.2 CHAPTER TWENTY-FIVE energy res

- Page 1185 and 1186:

25.4 CHAPTER TWENTY-FIVE Mitigating

- Page 1187 and 1188:

25.6 CHAPTER TWENTY-FIVE Energy Aud

- Page 1189 and 1190:

25.8 CHAPTER TWENTY-FIVE Green Buil

- Page 1191 and 1192:

25.10 CHAPTER TWENTY-FIVE Energy St

- Page 1193 and 1194:

25.12 CHAPTER TWENTY-FIVE 25.5 CASE

- Page 1195 and 1196:

25.14 CHAPTER TWENTY-FIVE For both

- Page 1197 and 1198:

25.16 CHAPTER TWENTY-FIVE Unit elec

- Page 1199 and 1200:

25.18 CHAPTER TWENTY-FIVE Physical

- Page 1201 and 1202:

25.20 CHAPTER TWENTY-FIVE condensin

- Page 1203 and 1204:

25.22 CHAPTER TWENTY-FIVE Condenser

- Page 1205 and 1206:

25.24 CHAPTER TWENTY-FIVE The polyn

- Page 1207 and 1208:

25.26 CHAPTER TWENTY-FIVE Loads Sys

- Page 1209 and 1210:

25.28 CHAPTER TWENTY-FIVE ● Recip

- Page 1211 and 1212:

25.30 CHAPTER TWENTY-FIVE Scientifi

- Page 1213 and 1214:

26.2 CHAPTER TWENTY-SIX The purpose

- Page 1215 and 1216:

26.4 CHAPTER TWENTY-SIX requiring l

- Page 1217 and 1218:

26.6 CHAPTER TWENTY-SIX the nutriti

- Page 1219 and 1220:

26.8 CHAPTER TWENTY-SIX Space Limit

- Page 1221 and 1222:

26.10 CHAPTER TWENTY-SIX and throug

- Page 1223 and 1224:

26.12 CHAPTER TWENTY-SIX Controls F

- Page 1225 and 1226:

26.14 CHAPTER TWENTY-SIX Exterior l

- Page 1227 and 1228:

26.16 CHAPTER TWENTY-SIX Harold, R.

- Page 1229 and 1230:

27.2 CHAPTER TWENTY-SEVEN condition

- Page 1231 and 1232:

27.4 CHAPTER TWENTY-SEVEN 2. Water-

- Page 1233 and 1234:

27.6 CHAPTER TWENTY-SEVEN TABLE 27.

- Page 1235 and 1236:

27.8 CHAPTER TWENTY-SEVEN FIGURE 27

- Page 1237 and 1238:

27.10 CHAPTER TWENTY-SEVEN Effectiv

- Page 1239 and 1240:

27.12 CHAPTER TWENTY-SEVEN consumpt

- Page 1241 and 1242:

50 50 13.0 27.14 40 40 60 60 50 50

- Page 1243 and 1244:

27.16 CHAPTER TWENTY-SEVEN Assume t

- Page 1245 and 1246:

27.18 CHAPTER TWENTY-SEVEN System C

- Page 1247 and 1248:

27.20 CHAPTER TWENTY-SEVEN If the e

- Page 1249 and 1250:

27.22 CHAPTER TWENTY-SEVEN coil and

- Page 1251 and 1252:

27.24 CHAPTER TWENTY-SEVEN warm and

- Page 1253 and 1254:

27.26 CHAPTER TWENTY-SEVEN REFERENC

- Page 1255 and 1256:

CHAPTER 28 AIR CONDITIONING SYSTEMS

- Page 1257 and 1258:

Induction Systems annoying. A recei

- Page 1259 and 1260:

Fan-Coil Units AIR CONDITIONING SYS

- Page 1261 and 1262:

Volume Flow Rate Fan Motor. Permane

- Page 1263 and 1264:

Heating Capacity If the sensible he

- Page 1265 and 1266:

where � ps � air density of out

- Page 1267 and 1268:

Part-Load Operation At cooling mode

- Page 1269 and 1270:

TABLE 28.1 System Characteristics o

- Page 1271 and 1272:

AIR CONDITIONING SYSTEMS: SPACE CON

- Page 1273 and 1274:

where w s � humidity ratio of fan

- Page 1275 and 1276:

In a typical nonchangeover two-pipe

- Page 1277 and 1278:

For all the rooms in the perimeter

- Page 1279 and 1280:

Loop Temperatures AIR CONDITIONING

- Page 1281 and 1282:

leaving condition of 60°F (15.6°C

- Page 1283 and 1284:

Water Heater Storage Tanks heat pum

- Page 1285 and 1286:

System Characteristics starts the f

- Page 1287 and 1288:

● If ceiling units are used, good

- Page 1289 and 1290:

CHAPTER 29 AIR CONDITIONING SYSTEMS

- Page 1291 and 1292:

Applications AC SYSTEMS: PACKAGED A

- Page 1293 and 1294:

Controls Energy Use Intensities Sys

- Page 1295 and 1296:

29.3 SINGLE-ZONE VAV PACKAGED SYSTE

- Page 1297 and 1298:

d. That is capable of being set bac

- Page 1299 and 1300:

volume flow rate when the total pre

- Page 1301 and 1302:

FIGURE 29.2 A VAV reheat packaged s

- Page 1303 and 1304:

liquid slugging. Liquid slugging ma

- Page 1305 and 1306:

A VAV packaged system is shut off d

- Page 1307 and 1308:

more widely used. Fan-powered VAV p

- Page 1309 and 1310:

AC SYSTEMS: PACKAGED AND DESICCANT-

- Page 1311 and 1312:

AC SYSTEMS: PACKAGED AND DESICCANT-

- Page 1313 and 1314:

FIGURE 29.4 A desiccant-based air c

- Page 1315 and 1316:

As defined in Sec. 3.4, a sorption

- Page 1317 and 1318:

flow rate of the mixture of the pro

- Page 1319 and 1320:

Part-Load Operation and Controls Wh

- Page 1321 and 1322:

System Description AC SYSTEMS: PACK

- Page 1323 and 1324:

System Characteristics REFERENCES A

- Page 1325 and 1326:

CHAPTER 30 AIR CONDITIONING SYSTEMS

- Page 1327 and 1328:

● Special process temperature and

- Page 1329 and 1330:

Air and Water Temperature Different

- Page 1331 and 1332:

of a VAV system using inlet vane mo

- Page 1333 and 1334:

System Characterisics System charac

- Page 1335 and 1336:

System Characteristics the supply a

- Page 1337 and 1338:

System Characteristics AC SYSTEMS:

- Page 1339 and 1340:

FIGURE 30.1 A clean-room system for

- Page 1341 and 1342:

Manufacturing an integrated circuit

- Page 1343 and 1344:

Summer Mode Operation Room temperat

- Page 1345 and 1346:

System Pressure AC SYSTEMS: CENTRAL

- Page 1347 and 1348:

FIGURE 30.2 (Continued) Effect of F

- Page 1349 and 1350:

AC SYSTEMS: CENTRAL SYSTEMS AND CLE

- Page 1351 and 1352:

31.2 CHAPTER THIRTY-ONE mechanical

- Page 1353 and 1354:

31.4 CHAPTER THIRTY-ONE Refrigerati

- Page 1355 and 1356:

31.6 CHAPTER THIRTY-ONE 31.2 ICE-ON

- Page 1357 and 1358:

31.8 CHAPTER THIRTY-ONE FIGURE 31.3

- Page 1359 and 1360:

31.10 CHAPTER THIRTY-ONE TABLE 31.1

- Page 1361 and 1362:

31.12 CHAPTER THIRTY-ONE Water leve

- Page 1363 and 1364:

31.14 CHAPTER THIRTY-ONE Location o

- Page 1365 and 1366:

31.16 CHAPTER THIRTY-ONE FIGURE 31.

- Page 1367 and 1368:

31.18 CHAPTER THIRTY-ONE In additio

- Page 1369 and 1370:

31.20 CHAPTER THIRTY-ONE Temperatur

- Page 1371 and 1372:

31.22 CHAPTER THIRTY-ONE volume flo

- Page 1373 and 1374:

31.24 CHAPTER THIRTY-ONE Storage co

- Page 1375 and 1376:

31.26 CHAPTER THIRTY-ONE Charging P

- Page 1377 and 1378:

31.28 CHAPTER THIRTY-ONE System Per

- Page 1379 and 1380:

CHAPTER 32 COMMISSIONING AND MAINTE

- Page 1381 and 1382:

● Clarifly owner priorities and d

- Page 1383 and 1384:

intent. The CC also makes sure that

- Page 1385 and 1386:

APPENDIX A NOMENCLATURE AND ABBREVI

- Page 1387 and 1388:

I DN i m I a I rad I ref I t solar

- Page 1389 and 1390:

SC shadding coefficient Sc Schmidt

- Page 1391 and 1392:

2g second-stage generator go satura

- Page 1393 and 1394:

� relative humidity, percent; sol

- Page 1395 and 1396:

APPENDIX B PSYCHROMETRIC CHART, TAB

- Page 1397 and 1398:

B.3 TABLE B.1 Thermodynamic Propert

- Page 1399 and 1400:

TABLE B.2 Physical Properties of Ai

- Page 1401:

PSYCHROMETRIC CHART, TABLES OF PROP