xxiii Ïανελληνιο ÏÏ Î½ÎµÎ´Ïιο ÏÏ ÏÎ¹ÎºÎ·Ï ÏÏεÏÎµÎ±Ï ÎºÎ±ÏαÏÏαÏÎ·Ï & εÏιÏÏÎ·Î¼Î·Ï ...

xxiii Ïανελληνιο ÏÏ Î½ÎµÎ´Ïιο ÏÏ ÏÎ¹ÎºÎ·Ï ÏÏεÏÎµÎ±Ï ÎºÎ±ÏαÏÏαÏÎ·Ï & εÏιÏÏÎ·Î¼Î·Ï ...

xxiii Ïανελληνιο ÏÏ Î½ÎµÎ´Ïιο ÏÏ ÏÎ¹ÎºÎ·Ï ÏÏεÏÎµÎ±Ï ÎºÎ±ÏαÏÏαÏÎ·Ï & εÏιÏÏÎ·Î¼Î·Ï ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Structure and Magnetic Properties of Pr(Fe,Co,Ti,Cu,Zr) 9.66<br />

Melt-spun Nanostructured Alloys<br />

M. Gjoka 1 *, D. Niarchos 1 , C. Sarafidis 2 , O. Kalogirou 2 , M. Grigoras 3 , N. Lupu 3 and H. Chiriac 3<br />

1 Institute of Materials Science, N.C.S.R. “Demokritos” Agia Paraskevi 15310 Athens, Greece<br />

2 Dept. of Physics, Aristotle University of Thessaloniki, 54 124 Thessaloniki, Greece<br />

3 National Institute of R&D for Technical Physics, 47 Mangeron Blvd., 700050 Iasi, Romania<br />

* gjoka@ims.demokritos.gr<br />

Abstract<br />

Pr(Fe,Co,Ti,Cu,Zr) 9.66 alloys were prepared by the melt-spinning technique with a velocity of 40 and 30 ms −1 . Annealing of<br />

the melt-spun ribbons resulted in the formation of hexagonal TbCu 7 -type structure. The saturation magnetization of the<br />

TbCu 7 -type phase was found to be 152.0 Am 2 kg −1 at room temperature. The annealed ribbons have low coercivity values<br />

attributed to the presence of the soft α-Fe(Co) phase (under certain experimental conditions).<br />

1. Introduction<br />

Nanophase materials have attracted considerable interest in the last few years [1] because of their unusual scientific and<br />

technological properties. The breakthrough for the search on nanophase materials using the melt-spinning technique, by<br />

Hadjipanayis et al. and Croat et al., remain important up today for the production of nanophase magnets. One of the rare<br />

earth compounds for the new permanent magnet applications is the R 3 (Fe,M) 29 (R: rare earth and M: transition metal) phase.<br />

This R 3 (Fe,M) 29 phase is described as an alternate stacking of the R(Fe,M) 12 phase (tetragonal ThMn 12 -type structure) and the<br />

R 2 (Fe,M) 17 phase (rhombohedral Th 2 Zn 17 -type structure. There are some reports of melt-spinning on the Re 3 (FeT) 29 system<br />

(R = Ce, Pr, Nd and T = Ti, Cr) [2- 5 ]. Sm(Co bal Fe 0.19 Cu 0.1 Ti 0.05 ) 9.66 melt-spun powder magnets have been fabricated [6]. In<br />

this work we report the production and magnetic properties of the Pr[Fe x Co 0.284 Ti z Cu w1 Zr w2 ] 9.66 (x+z+w 1 +w 2 = 0.716) meltspun<br />

nanostructured alloys.<br />

2. Experimental<br />

Pr[Fe x Co 0.284 Ti z Cu w1 Zr w2 ] 9.66 (x+z+w 1 +w 2 = 0.716) alloys were prepared by arc melting in an argon atmosphere. Small<br />

quantities of the alloy ingots were placed in a quartz crucible with an orifice of 0.6 mm in diameter at the bottom. The alloy<br />

ingots were induction-melted in an argon atmosphere and then ejected through the orifice under argon pressure onto a<br />

chromium-plated copper wheel rotating at a surface velocity of 40 and 30 ms −1 . The resultant melt-spun ribbons were<br />

obtained as fragmented pieces. Typical dimensions of the ribbon fragments were 10 µm in thickness by 1 mm wide and 10-<br />

20 mm long. Heat treatments of the melt-spun ribbons were then carried out in an argon atmosphere at temperatures between<br />

700-850 0 C K for different times. The specimens were examined by X-ray powder diffraction (XRD) using CuKα radiation.<br />

The magnetization of the powders was examined at a heating rate of 5°C/min in vacuum using a vibrating sample<br />

magnetometer (VSM) at an applied field of 200 Oe. The hysteresis loops of the specimens were measured at room<br />

temperature by VSM under a maximum applied field of 2.0 Tesla.<br />

3. Results and discussion<br />

Intensity (arb. units)<br />

a)<br />

b)<br />

c)<br />

(101)<br />

(110)<br />

(111)<br />

(002)<br />

20 40<br />

2-theta (degree)<br />

(200)<br />

(201)<br />

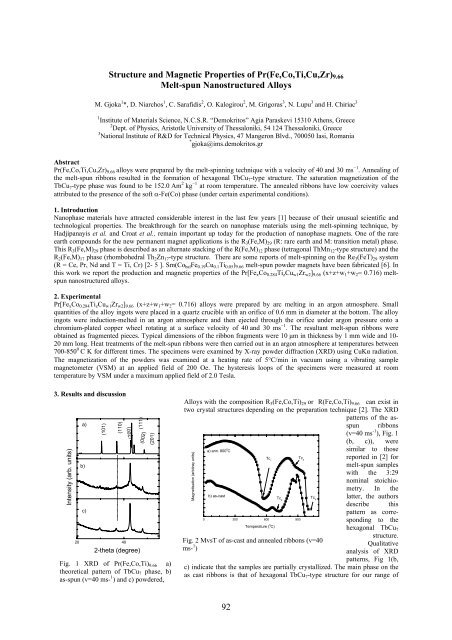

Fig. 1 XRD of Pr(Fe,Co,Ti) 9.66 a)<br />

theoretical pattern of TbCu 7 phase, b)<br />

as-spun (v=40 ms- 1 ) and c) powdered,<br />

Tc 1<br />

Alloys with the composition R 3 (Fe,Co,Ti) 29 or R(Fe,Co,Ti) 9.66 can exist in<br />

two crystal structures depending on the preparation technique [2]. The XRD<br />

patterns of the asspun<br />

ribbons<br />

(v=40 ms -1 ), Fig. 1<br />

(b, c)), were<br />

a) ann. 800 0 C<br />

similar to those<br />

Tc 3<br />

reported in [2] for<br />

melt-spun samples<br />

with the 3:29<br />

nominal stoichiometry.<br />

In the<br />

b) as-cast<br />

Tc Tc<br />

2<br />

4<br />

latter, the authors<br />

describe this<br />

pattern as corresponding<br />

0 300 600<br />

Temperature ( 0 C)<br />

900<br />

to the<br />

hexagonal TbCu 7<br />

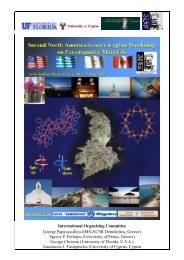

Fig. 2 MvsT of as-cast and annealed ribbons (v=40<br />

ms- 1 )<br />

structure.<br />

Qualitative<br />

analysis of XRD<br />

patterns, Fig 1(b,<br />

c) indicate that the samples are partially crystallized. The main phase on the<br />

as cast ribbons is that of hexagonal TbCu 7 -type structure for our range of<br />

Magnetisation (arbitray units)<br />

92