xxiii Ïανελληνιο ÏÏ Î½ÎµÎ´Ïιο ÏÏ ÏÎ¹ÎºÎ·Ï ÏÏεÏÎµÎ±Ï ÎºÎ±ÏαÏÏαÏÎ·Ï & εÏιÏÏÎ·Î¼Î·Ï ...

xxiii Ïανελληνιο ÏÏ Î½ÎµÎ´Ïιο ÏÏ ÏÎ¹ÎºÎ·Ï ÏÏεÏÎµÎ±Ï ÎºÎ±ÏαÏÏαÏÎ·Ï & εÏιÏÏÎ·Î¼Î·Ï ...

xxiii Ïανελληνιο ÏÏ Î½ÎµÎ´Ïιο ÏÏ ÏÎ¹ÎºÎ·Ï ÏÏεÏÎµÎ±Ï ÎºÎ±ÏαÏÏαÏÎ·Ï & εÏιÏÏÎ·Î¼Î·Ï ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

30<br />

0<br />

-30<br />

-900 -600 -300 0 300 600 900<br />

40<br />

20<br />

0<br />

-20<br />

-40<br />

-60<br />

-1,5 -1,0 -0,5 0,0 0,5 1,0<br />

quenching speeds (40 and 30 ms -1 ). From the relative intensities of the reflection (200) of the as-cast and annealed samples it<br />

was concluded that they were textured. Thermomagnetic analysis curve for as-spun ribbons (40 ms -1 ) showed a broad<br />

transition, in the range 300–600 0 C which corresponds to amorphous state, and three other transitions Tc 2 = 706 0 (5), Tc 3<br />

=876 0 (5) and Tc 4 around T>1000 0 C, Fig 2. The last transition corresponds probably to α-Co . After annealing at 800 0 C for<br />

15 min Tc 2 disappears, the 1:7 phase is know crystallized with Tc = 570 0 C, the phase with Tc 3 could be the 1:12 phase<br />

favorable for annealing at relatively low temperature.<br />

From the EDAX analysis it was found that the as-spun samples had a mean composition Pr(Fe 0.65 Co 0.27 Ti 0.068 ) 8.44 for the<br />

ribbons produced with velocity of 30 m/s and Pr(Fe 0.67 Co 0.275 Ti 0.05 ) 9.43 (ribbons produced with 40 ms -1 ). The last composition<br />

Magnetisation(Am 2 /kg)<br />

150<br />

75<br />

0<br />

-75<br />

Pr(FeCoTi) 9.66<br />

An. 850 0 C<br />

v=40 m/s<br />

-150<br />

-20 -10 0 10 20<br />

Magnetic field (kOe)<br />

M(emu/g)<br />

H(Oe)<br />

-20 -10 0 10 20<br />

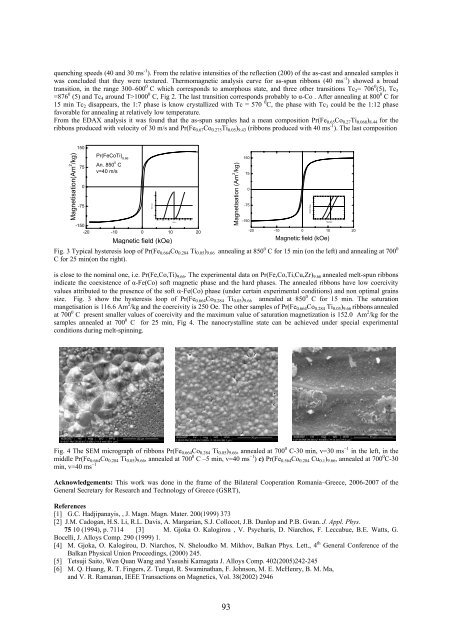

Fig. 3 Typical hysteresis loop of Pr(Fe 0.664 Co 0.284 Ti 0.05 ) 9.66 annealing at 850 0 C for 15 min (on the left) and annealing at 700 0<br />

C for 25 min(on the right).<br />

Magnetisation (Am 2 /kg)<br />

150<br />

75<br />

0<br />

-75<br />

-150<br />

M(Am 2 /kg)<br />

H(kOe)<br />

Magnetic field (kOe)<br />

is close to the nominal one, i.e. Pr(Fe,Co,Ti) 9.66 . The experimental data on Pr(Fe,Co,Ti,Cu,Zr) 9.66 annealed melt-spun ribbons<br />

indicate the coexistence of α-Fe(Co) soft magnetic phase and the hard phases. The annealed ribbons have low coercivity<br />

values attributed to the presence of the soft α-Fe(Co) phase (under certain experimental conditions) and non optimal grains<br />

size. Fig. 3 show the hysteresis loop of Pr(Fe 0.664 Co 0.284 Ti 0.05 ) 9.66 annealed at 850 0 C for 15 min. The saturation<br />

mangetisation is 116.6 Am 2 /kg and the coercivity is 250 Oe. The other samples of Pr(Fe 0.664 Co 0.284 Ti 0.05 ) 9.66 ribbons annealed<br />

at 700 0 C present smaller values of coercivity and the maximum value of saturation magnetization is 152.0 Am 2 /kg for the<br />

samples annealed at 700 0 C for 25 min, Fig 4. The nanocrystalline state can be achieved under special experimental<br />

conditions during melt-spinning.<br />

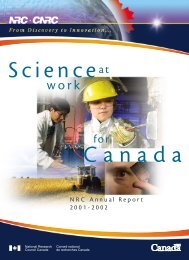

Fig. 4 The SEM micrograph of ribbons Pr(Fe 0.664 Co 0.284 Ti 0.05 ) 9.66 , annealed at 700 0 C-30 min, v=30 ms −1 in the left, in the<br />

middle Pr(Fe 0.664 Co 0.284 Ti 0.05 ) 9.66 , annealed at 700 0 C –5 min, v=40 ms −1 ) c) Pr(Fe 0.564 Co 0.284 Cu 0.1 ) 9.66 , annealed at 700 0 C-30<br />

min, v=40 ms −1<br />

Acknowledgements: This work was done in the frame of the Bilateral Cooperation Romania–Greece, 2006-2007 of the<br />

General Secretary for Research and Technology of Greece (GSRT),<br />

References<br />

[1] G.C. Hadjipanayis, , J. Magn. Magn. Mater. 200(1999) 373<br />

[2] J.M. Cadogan, H.S. Li, R.L. Davis, A. Margarian, S.J. Collocot, J.B. Dunlop and P.B. Gwan. J. Appl. Phys.<br />

75 10 (1994), p. 7114 [3] M. Gjoka O. Kalogirou , V. Psycharis, D. Niarchos, F. Leccabue, B.E. Watts, G.<br />

Bocelli, J. Alloys Comp. 290 (1999) 1.<br />

[4] M. Gjoka, O. Kalogirou, D. Niarchos, N. Sheloudko M. Mikhov, Balkan Phys. Lett., 4 th General Conference of the<br />

Balkan Physical Union Proceedings, (2000) 245.<br />

[5] Tetsuji Saito, Wen Quan Wang and Yasushi Kamagata J. Alloys Comp. 402(2005)242-245<br />

[6] M. Q. Huang, R. T. Fingers, Z. Turqut, R. Swaminathan, F. Johnson, M. E. McHenry, B. M. Ma,<br />

and V. R. Ramanan, IEEE Transactions on Magnetics, Vol. 38(2002) 2946<br />

93