xxiii Ïανελληνιο ÏÏ Î½ÎµÎ´Ïιο ÏÏ ÏÎ¹ÎºÎ·Ï ÏÏεÏÎµÎ±Ï ÎºÎ±ÏαÏÏαÏÎ·Ï & εÏιÏÏÎ·Î¼Î·Ï ...

xxiii Ïανελληνιο ÏÏ Î½ÎµÎ´Ïιο ÏÏ ÏÎ¹ÎºÎ·Ï ÏÏεÏÎµÎ±Ï ÎºÎ±ÏαÏÏαÏÎ·Ï & εÏιÏÏÎ·Î¼Î·Ï ...

xxiii Ïανελληνιο ÏÏ Î½ÎµÎ´Ïιο ÏÏ ÏÎ¹ÎºÎ·Ï ÏÏεÏÎµÎ±Ï ÎºÎ±ÏαÏÏαÏÎ·Ï & εÏιÏÏÎ·Î¼Î·Ï ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

V th<br />

(V)<br />

G m,max<br />

/G m,max0<br />

(%)<br />

I d<br />

(mA)<br />

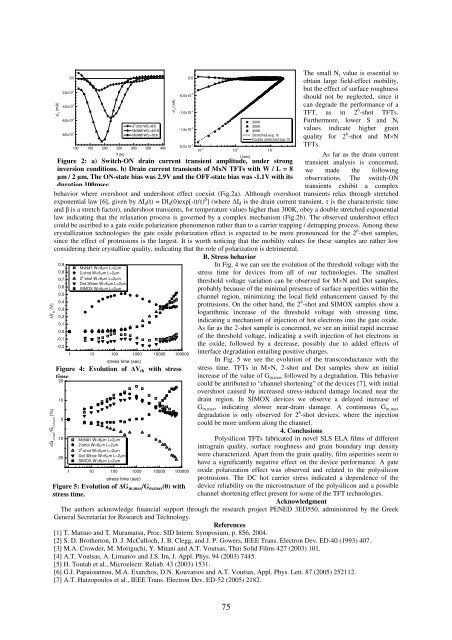

Figure 2: a) Switch-ON drain current transient amplitude, under strong<br />

inversion conditions. b) Drain current transients of MxN TFTs with W / L = 8<br />

m / 2 m. The -state bias was 2.9V and the OFF-state bias was -1.1V with its<br />

The small N t value is essential to<br />

obtain large field-effect mobility,<br />

but the effect of surface roughness<br />

should not be neglected, since it<br />

can degrade the performance of a<br />

TFT, as in 2 6 -shot TFTs.<br />

Furthermore, lower S and N t<br />

values indicate higher grain<br />

quality for 2 6 -shot and MN<br />

TFTs.<br />

As far as the drain current<br />

transient analysis is concerned,<br />

we made the following<br />

observations. The switch-ON<br />

transients exhibit a complex<br />

duration 100msec.<br />

behavior where overshoot and undershoot effect coexist (Fig.2a). Although overshoot transients relax through stretched<br />

exponential law [6], given by I d (t) = D d (0)exp[-(t/) ] (where I d is the drain current transient, is the characteristic time<br />

and is a stretch factor), undershoot transients, for temperature values higher than 300K, obey a double stretched exponential<br />

law indicating that the relaxation process is governed by a complex mechanism (Fig.2b). The observed undershoot effect<br />

could be ascribed to a gate oxide polarization phenomenon rather than to a carrier trapping / detrapping process. Among these<br />

crystallization technologies the gate oxide polarization effect is expected to be more pronounced for the 2 6 -shot samples,<br />

since the effect of protrusions is the largest. It is worth noticing that the mobility values for these samples are rather low<br />

considering their crystalline quality, indicating that the role of polarization is detrimental.<br />

B. Stress behavior<br />

0,9<br />

0,8<br />

0,7<br />

0,6<br />

0,5<br />

0,4<br />

0,3<br />

0,2<br />

0,1<br />

0,0<br />

-0,1<br />

-0,2<br />

20<br />

10<br />

0<br />

-10<br />

-20<br />

0,0<br />

-2,0x10 -4<br />

-4,0x10 -4<br />

-6,0x10 -4<br />

-8,0x10 -4<br />

100 150 200 250 300 350 400<br />

T (K)<br />

MxN#1 W=8m L=2m<br />

2-shot W=8m L=2m<br />

2 6 -shot W=8m L=2m<br />

Dot 30hex W=6m L=2m<br />

SIMOX W=8m L=2m<br />

1 10 100 1000 10000 100000<br />

stress time (sec)<br />

MxN#1 W=8m L=2m<br />

2-shot W=8m L=2m<br />

2 6 -shot W=8m L=2m<br />

Dot 30hex W=6m L=2m<br />

SIMOX W=8m L=2m<br />

2 6 -shot W/L=8/5<br />

MxN#8 W/L=4/0.8<br />

MxN#8 W/L=16/8<br />

Figure 4: Evolution of V th with stress<br />

time.<br />

1 10 100 1000 10000 100000<br />

stress time (sec)<br />

Figure 5: Evolution of G m,max /G m,max (0) with<br />

stress time.<br />

I d (mA)<br />

0,0<br />

-5,0x10 -5<br />

-1,0x10 -4<br />

-1,5x10 -4<br />

-2,0x10 -4<br />

200K<br />

300K<br />

400K<br />

Stretched exp. fit<br />

Double stretched exp. fit<br />

10 -3 10 -2 10 -1<br />

In Fig. 4 we can see the evolution of the threshold voltage with the<br />

stress time for devices from all of our technologies. The smallest<br />

threshold voltage variation can be observed for MN and Dot samples,<br />

probably because of the minimal presence of surface asperities within the<br />

channel region, minimizing the local field enhancement caused by the<br />

protrusions. On the other hand, the 2 6 -shot and SIMOX samples show a<br />

logarithmic increase of the threshold voltage with stressing time,<br />

indicating a mechanism of injection of hot electrons into the gate oxide.<br />

As far as the 2-shot sample is concerned, we see an initial rapid increase<br />

of the threshold voltage, indicating a swift injection of hot electrons in<br />

the oxide, followed by a decrease, possibly due to added effects of<br />

interface degradation entailing positive charges.<br />

In Fig. 5 we see the evolution of the transconductance with the<br />

stress time. TFTs in MN, 2-shot and Dot samples show an initial<br />

increase of the value of G m,max followed by a degradation. This behavior<br />

could be attributed to “channel shortening” of the devices [7], with initial<br />

overshoot caused by increased stress-induced damage located near the<br />

drain region. In SIMOX devices we observe a delayed increase of<br />

G m,max , indicating slower near-drain damage. A continuous G m,max<br />

degradation is only observed for 2 6 -shot devices, where the injection<br />

could be more uniform along the channel.<br />

4. Conclusions<br />

Polysilicon TFTs fabricated in novel SLS ELA films of different<br />

intragrain quality, surface roughness and grain boundary trap density<br />

were characterized. Apart from the grain quality, film asperities seem to<br />

have a significantly negative effect on the device performance. A gate<br />

oxide polarization effect was observed and related to the polysilicon<br />

protrusions. The DC hot carrier stress indicated a dependence of the<br />

device reliability on the microstructure of the polysilicon and a possible<br />

channel shortening effect present for some of the TFT technologies.<br />

Acknowledgment<br />

The authors acknowledge financial support through the research project PENED 3ED550, administered by the Greek<br />

General Secretariat for Research and Technology.<br />

References<br />

[1] T. Matsuo and T. Muramatsu, Proc. SID Intern. Symposium, p. 856, 2004.<br />

[2] S. D. Brotherton, D. J. McCulloch, J. B. Clegg, and J. P. Gowers, IEEE Trans. Electron Dev. ED-40 (1993) 407.<br />

[3] M.A. Crowder, M. Moriguchi, Y. Mitani and A.T. Voutsas, Thin Solid Films 427 (2003) 101.<br />

[4] A.T. Voutsas, A. Limanov and J.S. Im, J. Appl. Phys. 94 (2003) 7445.<br />

[5] H. Toutah et al., Microelectr. Reliab. 43 (2003) 1531.<br />

[6] G.J. Papaioannou, M.A. Exarchos, D.N. Kouvatsos and A.T. Voutsas, Appl. Phys. Lett. 87 (2005) 252112.<br />

[7] A.T. Hatzopoulos et al., IEEE Trans. Electron Dev. ED-52 (2005) 2182.<br />

t (sec)<br />

75