xxiii Ïανελληνιο ÏÏ Î½ÎµÎ´Ïιο ÏÏ ÏÎ¹ÎºÎ·Ï ÏÏεÏÎµÎ±Ï ÎºÎ±ÏαÏÏαÏÎ·Ï & εÏιÏÏÎ·Î¼Î·Ï ...

xxiii Ïανελληνιο ÏÏ Î½ÎµÎ´Ïιο ÏÏ ÏÎ¹ÎºÎ·Ï ÏÏεÏÎµÎ±Ï ÎºÎ±ÏαÏÏαÏÎ·Ï & εÏιÏÏÎ·Î¼Î·Ï ...

xxiii Ïανελληνιο ÏÏ Î½ÎµÎ´Ïιο ÏÏ ÏÎ¹ÎºÎ·Ï ÏÏεÏÎµÎ±Ï ÎºÎ±ÏαÏÏαÏÎ·Ï & εÏιÏÏÎ·Î¼Î·Ï ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

100<br />

90<br />

8<br />

7<br />

Intensity (arb.unit)<br />

0h<br />

80h<br />

140<br />

160<br />

5 10 15 20 25 30 35 40 45 50 55 60<br />

2Θ( o )<br />

Crystallite size (nm)<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

5mm balls<br />

0.6mm balls<br />

0<br />

20 40 60 80 100 120 140 160 180<br />

Milling time (h)<br />

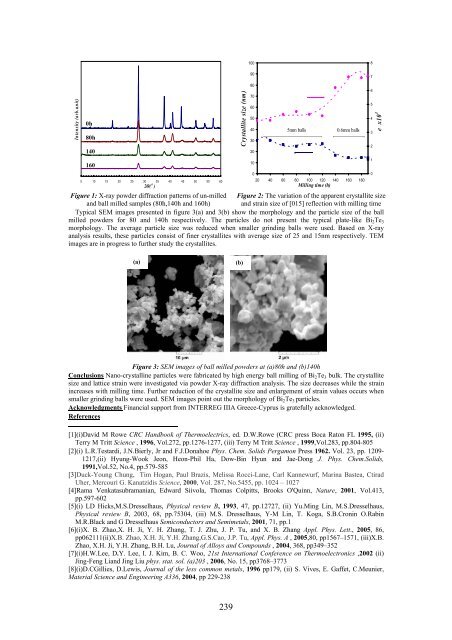

Figure 1: X-ray powder diffraction patterns of un-milled Figure 2: The variation of the apparent crystallite size<br />

and ball milled samples (80h,140h and 160h) and strain size of [015] reflection with milling time<br />

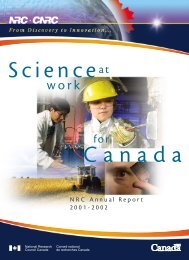

Typical SEM images presented in figure 3(a) and 3(b) show the morphology and the particle size of the ball<br />

milled powders for 80 and 140h respectively. The particles do not present the typical plate-like Bi 2 Te 3<br />

morphology. The average particle size was reduced when smaller grinding balls were used. Based on X-ray<br />

analysis results, these particles consist of finer crystallites with average size of 25 and 15nm respectively. TEM<br />

images are in progress to further study the crystallites.<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

e x10 3<br />

(a)<br />

(b)<br />

Figure 3: SEM images of ball milled powders at (a)80h and (b)140h<br />

Conclusions Nano-crystalline particles were fabricated by high energy ball milling of Bi 2 Te 3 bulk. The crystallite<br />

size and lattice strain were investigated via powder X-ray diffraction analysis. The size decreases while the strain<br />

increases with milling time. Further reduction of the crystallite size and enlargement of strain values occurs when<br />

smaller grinding balls were used. SEM images point out the morphology of Bi 2 Te 3 particles.<br />

Acknowledgments Financial support from INTERREG IIIA Greece-Cyprus is gratefully acknowledged.<br />

References<br />

[1](i)David M Rowe CRC Handbook of Thermoelectrics, ed. D.W.Rowe (CRC press Boca Raton FL 1995, (ii)<br />

Terry M Tritt Science , 1996, Vol.272, pp.1276-1277, (iii) Terry M Tritt Science , 1999,Vol.283, pp.804-805<br />

[2](i) L.R.Testardi, J.N.Bierly, Jr and F.J.Donahoe Phys. Chem. Solids Pergamon Press 1962. Vol. 23, pp. 1209-<br />

1217,(ii) Hyung-Wook Jeon, Heon-Phil Ha, Dow-Bin Hyun and Jae-Dong J. Phys. Chem.Solids,<br />

1991,Vol.52, No.4, pp.579-585<br />

[3]Duck-Young Chung, Tim Hogan, Paul Brazis, Melissa Rocci-Lane, Carl Kannewurf, Marina Bastea, Ctirad<br />

Uher, Mercouri G. Kanatzidis Science, 2000, Vol. 287, No.5455, pp. 1024 – 1027<br />

[4]Rama Venkatasubramanian, Edward Siivola, Thomas Colpitts, Brooks O'Quinn, Nature, 2001, Vol.413,<br />

pp.597-602<br />

[5](i) LD Hicks,M.S.Dresselhaus, Physical review B, 1993, 47, pp.12727, (ii) Yu.Ming Lin, M.S.Dresselhaus,<br />

Physical review B, 2003, 68, pp.75304, (iii) M.S. Dresselhaus, Y-M Lin, T. Koga, S.B.Cronin O.Rabin<br />

M.R.Black and G Dresselhaus Semiconductors and Semimetals, 2001, 71, pp.1<br />

[6](i)X. B. Zhao,X. H. Ji, Y. H. Zhang, T. J. Zhu, J. P. Tu, and X. B. Zhang Appl. Phys. Lett., 2005, 86,<br />

pp062111(ii)X.B. Zhao, X.H. Ji, Y.H. Zhang,G.S.Cao, J.P. Tu, Appl. Phys. A , 2005,80, pp1567–1571, (iii)X.B.<br />

Zhao, X.H. Ji, Y.H. Zhang, B.H. Lu, Journal of Alloys and Compounds , 2004, 368, pp349–352<br />

[7](i)H.W.Lee, D.Y. Lee, I. J. Kim, B. C. Woo, 21st International Conference on Thermoelectronics ,2002 (ii)<br />

Jing-Feng Liand Jing Liu phys. stat. sol. (a)203 , 2006, No. 15, pp3768–3773<br />

[8](i)D.CGillies, D.Lewis, Journal of the less common metals, 1996 pp179, (ii) S. Vives, E. Gaffet, C.Meunier,<br />

Material Science and Engineering A336, 2004, pp 229-238<br />

239