Proceedings of the 12th European Conference on Knowledge ...

Proceedings of the 12th European Conference on Knowledge ...

Proceedings of the 12th European Conference on Knowledge ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

John T Young<br />

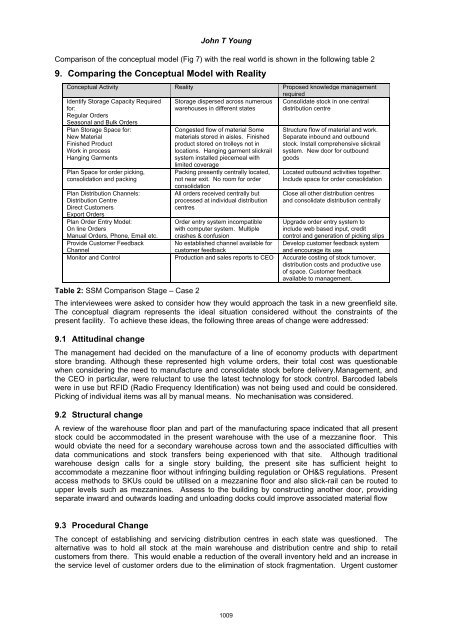

Comparis<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> c<strong>on</strong>ceptual model (Fig 7) with <str<strong>on</strong>g>the</str<strong>on</strong>g> real world is shown in <str<strong>on</strong>g>the</str<strong>on</strong>g> following table 2<br />

9. Comparing <str<strong>on</strong>g>the</str<strong>on</strong>g> C<strong>on</strong>ceptual Model with Reality<br />

C<strong>on</strong>ceptual Activity Reality Proposed knowledge management<br />

required<br />

Identify Storage Capacity Required Storage dispersed across numerous C<strong>on</strong>solidate stock in <strong>on</strong>e central<br />

for:<br />

Regular Orders<br />

Seas<strong>on</strong>al and Bulk Orders<br />

warehouses in different states distributi<strong>on</strong> centre<br />

Plan Storage Space for:<br />

C<strong>on</strong>gested flow <str<strong>on</strong>g>of</str<strong>on</strong>g> material Some Structure flow <str<strong>on</strong>g>of</str<strong>on</strong>g> material and work.<br />

New Material<br />

materials stored in aisles. Finished Separate inbound and outbound<br />

Finished Product<br />

product stored <strong>on</strong> trolleys not in stock. Install comprehensive slickrail<br />

Work in process<br />

locati<strong>on</strong>s. Hanging garment slickrail system. New door for outbound<br />

Hanging Garments<br />

system installed piecemeal with<br />

limited coverage<br />

goods<br />

Plan Space for order picking, Packing presently centrally located, Located outbound activities toge<str<strong>on</strong>g>the</str<strong>on</strong>g>r.<br />

c<strong>on</strong>solidati<strong>on</strong> and packing<br />

not near exit. No room for order<br />

c<strong>on</strong>solidati<strong>on</strong><br />

Include space for order c<strong>on</strong>solidati<strong>on</strong><br />

Plan Distributi<strong>on</strong> Channels:<br />

All orders received centrally but Close all o<str<strong>on</strong>g>the</str<strong>on</strong>g>r distributi<strong>on</strong> centres<br />

Distributi<strong>on</strong> Centre<br />

processed at individual distributi<strong>on</strong> and c<strong>on</strong>solidate distributi<strong>on</strong> centrally<br />

Direct Customers<br />

Export Orders<br />

centres<br />

Plan Order Entry Model:<br />

Order entry system incompatible Upgrade order entry system to<br />

On line Orders<br />

with computer system. Multiple include web based input, credit<br />

Manual Orders, Ph<strong>on</strong>e, Email etc. crashes & c<strong>on</strong>fusi<strong>on</strong><br />

c<strong>on</strong>trol and generati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> picking slips<br />

Provide Customer Feedback<br />

No established channel available for Develop customer feedback system<br />

Channel<br />

customer feedback<br />

and encourage its use<br />

M<strong>on</strong>itor and C<strong>on</strong>trol Producti<strong>on</strong> and sales reports to CEO Accurate costing <str<strong>on</strong>g>of</str<strong>on</strong>g> stock turnover,<br />

distributi<strong>on</strong> costs and productive use<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> space. Customer feedback<br />

available to management.<br />

Table 2: SSM Comparis<strong>on</strong> Stage – Case 2<br />

The interviewees were asked to c<strong>on</strong>sider how <str<strong>on</strong>g>the</str<strong>on</strong>g>y would approach <str<strong>on</strong>g>the</str<strong>on</strong>g> task in a new greenfield site.<br />

The c<strong>on</strong>ceptual diagram represents <str<strong>on</strong>g>the</str<strong>on</strong>g> ideal situati<strong>on</strong> c<strong>on</strong>sidered without <str<strong>on</strong>g>the</str<strong>on</strong>g> c<strong>on</strong>straints <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

present facility. To achieve <str<strong>on</strong>g>the</str<strong>on</strong>g>se ideas, <str<strong>on</strong>g>the</str<strong>on</strong>g> following three areas <str<strong>on</strong>g>of</str<strong>on</strong>g> change were addressed:<br />

9.1 Attitudinal change<br />

The management had decided <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> manufacture <str<strong>on</strong>g>of</str<strong>on</strong>g> a line <str<strong>on</strong>g>of</str<strong>on</strong>g> ec<strong>on</strong>omy products with department<br />

store branding. Although <str<strong>on</strong>g>the</str<strong>on</strong>g>se represented high volume orders, <str<strong>on</strong>g>the</str<strong>on</strong>g>ir total cost was questi<strong>on</strong>able<br />

when c<strong>on</strong>sidering <str<strong>on</strong>g>the</str<strong>on</strong>g> need to manufacture and c<strong>on</strong>solidate stock before delivery.Management, and<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> CEO in particular, were reluctant to use <str<strong>on</strong>g>the</str<strong>on</strong>g> latest technology for stock c<strong>on</strong>trol. Barcoded labels<br />

were in use but RFID (Radio Frequency Identificati<strong>on</strong>) was not being used and could be c<strong>on</strong>sidered.<br />

Picking <str<strong>on</strong>g>of</str<strong>on</strong>g> individual items was all by manual means. No mechanisati<strong>on</strong> was c<strong>on</strong>sidered.<br />

9.2 Structural change<br />

A review <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> warehouse floor plan and part <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> manufacturing space indicated that all present<br />

stock could be accommodated in <str<strong>on</strong>g>the</str<strong>on</strong>g> present warehouse with <str<strong>on</strong>g>the</str<strong>on</strong>g> use <str<strong>on</strong>g>of</str<strong>on</strong>g> a mezzanine floor. This<br />

would obviate <str<strong>on</strong>g>the</str<strong>on</strong>g> need for a sec<strong>on</strong>dary warehouse across town and <str<strong>on</strong>g>the</str<strong>on</strong>g> associated difficulties with<br />

data communicati<strong>on</strong>s and stock transfers being experienced with that site. Although traditi<strong>on</strong>al<br />

warehouse design calls for a single story building, <str<strong>on</strong>g>the</str<strong>on</strong>g> present site has sufficient height to<br />

accommodate a mezzanine floor without infringing building regulati<strong>on</strong> or OH&S regulati<strong>on</strong>s. Present<br />

access methods to SKUs could be utilised <strong>on</strong> a mezzanine floor and also slick-rail can be routed to<br />

upper levels such as mezzanines. Assess to <str<strong>on</strong>g>the</str<strong>on</strong>g> building by c<strong>on</strong>structing ano<str<strong>on</strong>g>the</str<strong>on</strong>g>r door, providing<br />

separate inward and outwards loading and unloading docks could improve associated material flow<br />

9.3 Procedural Change<br />

The c<strong>on</strong>cept <str<strong>on</strong>g>of</str<strong>on</strong>g> establishing and servicing distributi<strong>on</strong> centres in each state was questi<strong>on</strong>ed. The<br />

alternative was to hold all stock at <str<strong>on</strong>g>the</str<strong>on</strong>g> main warehouse and distributi<strong>on</strong> centre and ship to retail<br />

customers from <str<strong>on</strong>g>the</str<strong>on</strong>g>re. This would enable a reducti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> overall inventory held and an increase in<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> service level <str<strong>on</strong>g>of</str<strong>on</strong>g> customer orders due to <str<strong>on</strong>g>the</str<strong>on</strong>g> eliminati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> stock fragmentati<strong>on</strong>. Urgent customer<br />

1009