sectoral economic costs and benefits of ghg mitigation - IPCC

sectoral economic costs and benefits of ghg mitigation - IPCC

sectoral economic costs and benefits of ghg mitigation - IPCC

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Energy Intensive Industries<br />

Costs <strong>and</strong> Benefits <strong>of</strong> CO 2 Mitigation in Energy Intensive<br />

Industries <strong>of</strong> India<br />

Somnath Bhattacharjee<br />

Introduction<br />

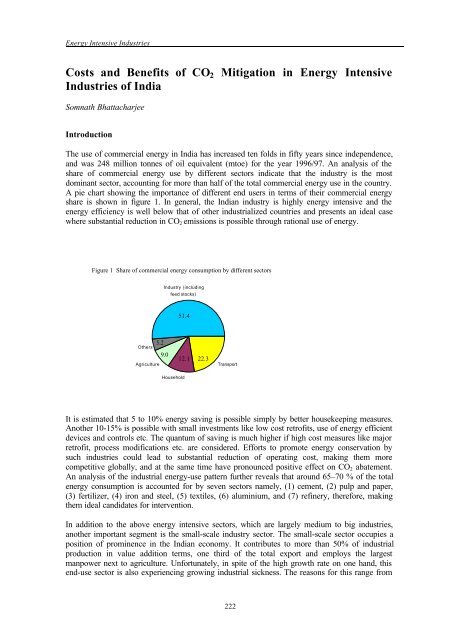

The use <strong>of</strong> commercial energy in India has increased ten folds in fifty years since independence,<br />

<strong>and</strong> was 248 million tonnes <strong>of</strong> oil equivalent (mtoe) for the year 1996/97. An analysis <strong>of</strong> the<br />

share <strong>of</strong> commercial energy use by different sectors indicate that the industry is the most<br />

dominant sector, accounting for more than half <strong>of</strong> the total commercial energy use in the country.<br />

A pie chart showing the importance <strong>of</strong> different end users in terms <strong>of</strong> their commercial energy<br />

share is shown in figure 1. In general, the Indian industry is highly energy intensive <strong>and</strong> the<br />

energy efficiency is well below that <strong>of</strong> other industrialized countries <strong>and</strong> presents an ideal case<br />

where substantial reduction in CO 2 emissions is possible through rational use <strong>of</strong> energy.<br />

Figure 1 Share <strong>of</strong> commercial energy consumption by different sectors<br />

Industry (including<br />

feed stocks)<br />

51.4<br />

Others<br />

Agriculture<br />

5.2<br />

9.0<br />

12.1<br />

22.3<br />

Transport<br />

Household<br />

It is estimated that 5 to 10% energy saving is possible simply by better housekeeping measures.<br />

Another 10-15% is possible with small investments like low cost retr<strong>of</strong>its, use <strong>of</strong> energy efficient<br />

devices <strong>and</strong> controls etc. The quantum <strong>of</strong> saving is much higher if high cost measures like major<br />

retr<strong>of</strong>it, process modifications etc. are considered. Efforts to promote energy conservation by<br />

such industries could lead to substantial reduction <strong>of</strong> operating cost, making them more<br />

competitive globally, <strong>and</strong> at the same time have pronounced positive effect on CO 2 abatement.<br />

An analysis <strong>of</strong> the industrial energy-use pattern further reveals that around 65–70 % <strong>of</strong> the total<br />

energy consumption is accounted for by seven sectors namely, (1) cement, (2) pulp <strong>and</strong> paper,<br />

(3) fertilizer, (4) iron <strong>and</strong> steel, (5) textiles, (6) aluminium, <strong>and</strong> (7) refinery, therefore, making<br />

them ideal c<strong>and</strong>idates for intervention.<br />

In addition to the above energy intensive sectors, which are largely medium to big industries,<br />

another important segment is the small-scale industry sector. The small-scale sector occupies a<br />

position <strong>of</strong> prominence in the Indian economy. It contributes to more than 50% <strong>of</strong> industrial<br />

production in value addition terms, one third <strong>of</strong> the total export <strong>and</strong> employs the largest<br />

manpower next to agriculture. Unfortunately, in spite <strong>of</strong> the high growth rate on one h<strong>and</strong>, this<br />

end-use sector is also experiencing growing industrial sickness. The reasons for this range from<br />

222