sectoral economic costs and benefits of ghg mitigation - IPCC

sectoral economic costs and benefits of ghg mitigation - IPCC

sectoral economic costs and benefits of ghg mitigation - IPCC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Somnath Bhattacharjee<br />

technological obsolescence, information deficiency <strong>and</strong> poor management practices to nonavailability<br />

<strong>of</strong> credits. There are some highly energy intensive sub sectors where the cost <strong>of</strong><br />

energy forms a sizeable proportion <strong>of</strong> the total production cost <strong>and</strong> <strong>of</strong>fers tremendous scope for<br />

energy efficiency improvement <strong>and</strong> pollution reduction through technology up gradation.<br />

As is clear from the preceding discussion, the energy intensive industries in India <strong>of</strong>fer huge<br />

potential for energy saving with a corresponding reduction in global as well as local emissions.<br />

The <strong>costs</strong> associated to affect this change <strong>and</strong> the associated <strong>benefits</strong> are, however, sector<br />

specific. In this paper, for illustrative purposes, three case studies are presented, primarily based<br />

on the research findings at TERI. These case studies pertain to two energy intensive sectors<br />

under large-scale industry namely pulp <strong>and</strong> paper <strong>and</strong> cement, <strong>and</strong> one energy intensive smallscale<br />

industry sector - the case iron foundry industry.<br />

Case Study I Pulp <strong>and</strong> paper industry<br />

The pulp <strong>and</strong> paper industry is one <strong>of</strong> the key industrial sectors in India, <strong>and</strong> is the country’s sixth<br />

largest consumer <strong>of</strong> energy. The energy cost presently accounts for about 25% <strong>of</strong> the total cost <strong>of</strong><br />

manufacturing, <strong>and</strong> is steadily rising every year. The average size <strong>of</strong> paper mills in India is only<br />

45tpd, as against 900tpd in Europe <strong>and</strong> North America. As against a total installed capacity <strong>of</strong> 4.3<br />

million tonnes (in 96/97), the production was only 3.26 million tonnes, on account <strong>of</strong> low<br />

capacity utilisation.<br />

Energy performance<br />

The main fuel used by the industry is coal, which accounts for about 70% <strong>of</strong> the total energy use.<br />

The primary energy consumption in the sector rose from 45.9 PJ in 1981–82 to 74.5 PJ in 1993–<br />

94.<br />

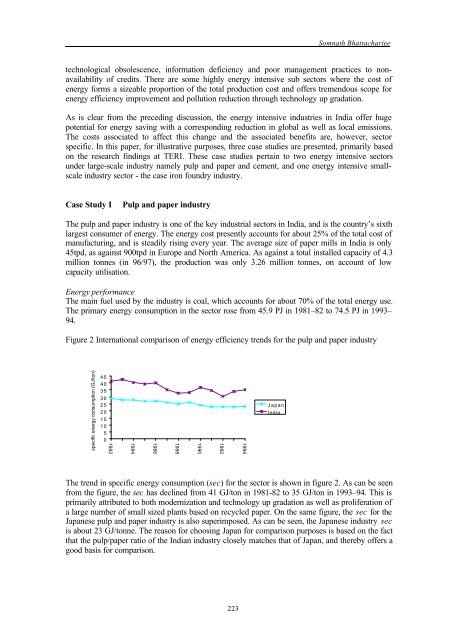

Figure 2 International comparison <strong>of</strong> energy efficiency trends for the pulp <strong>and</strong> paper industry<br />

specific energy consumption (GJ/ton)<br />

45<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

1982<br />

1984<br />

1986<br />

1988<br />

1990<br />

1992<br />

1994<br />

Japan<br />

India<br />

The trend in specific energy consumption (sec) for the sector is shown in figure 2. As can be seen<br />

from the figure, the sec has declined from 41 GJ/ton in 1981-82 to 35 GJ/ton in 1993–94. This is<br />

primarily attributed to both modernization <strong>and</strong> technology up gradation as well as proliferation <strong>of</strong><br />

a large number <strong>of</strong> small sized plants based on recycled paper. On the same figure, the sec for the<br />

Japanese pulp <strong>and</strong> paper industry is also superimposed. As can be seen, the Japanese industry sec<br />

is about 23 GJ/tonne. The reason for choosing Japan for comparison purposes is based on the fact<br />

that the pulp/paper ratio <strong>of</strong> the Indian industry closely matches that <strong>of</strong> Japan, <strong>and</strong> thereby <strong>of</strong>fers a<br />

good basis for comparison.<br />

223