- Page 1 and 2:

Models 5E, 5F, 5G &5H Electric Swit

- Page 3 and 4:

LIST OF EFFECTIVE PAGESP1293, Model

- Page 5 and 6:

PREFACENOTICE OF CONFIDENTIAL INFOR

- Page 7 and 8:

ABOUT THE MANUALThis manual is inte

- Page 9 and 10:

MANUAL SPECIAL NOTATIONSIn the Alst

- Page 11 and 12:

TopicTABLE OF CONTENTSPage1. SECTIO

- Page 13 and 14:

TopicTABLE OF CONTENTSPage4. SECTIO

- Page 15 and 16:

TopicTABLE OF CONTENTSPage6.5.32. C

- Page 17 and 18:

DescriptionLIST OF FIGURES (CONT.)P

- Page 19 and 20:

DescriptionLIST OF TABLESPageTable

- Page 21 and 22:

DescriptionLIST OF TABLES (CONT.)Pa

- Page 23 and 24:

General Description1. SECTION 1 - G

- Page 25 and 26:

General Description1.3. MODEL 5E, 5

- Page 27 and 28:

General Description1.4. MODEL 5 SER

- Page 29 and 30:

General DescriptionThe components i

- Page 31 and 32:

General Description1.5.2. Proper At

- Page 33 and 34:

General Description1.5.7. Safety at

- Page 35 and 36:

Theory of Operation2. SECTION 2 - T

- Page 37 and 38:

Theory of OperationFigure 2-3. Hand

- Page 39 and 40:

Theory of OperationFigure 2-5. Inse

- Page 41 and 42:

Theory of OperationThe locations of

- Page 43 and 44:

Theory of Operation2.5.1. MotorThe

- Page 45 and 46:

Theory of Operation2.5.1.1. Commuta

- Page 47 and 48:

Theory of OperationWhen the motor i

- Page 49 and 50:

Theory of OperationTHROWBARHAND CRA

- Page 51 and 52:

Theory of Operation2.5.3.1. Frictio

- Page 53 and 54:

Theory of OperationFinal cam bar mo

- Page 55 and 56:

Theory of Operation2.5.5. Lock RodT

- Page 57 and 58:

Theory of Operation2.5.6. Point Det

- Page 59 and 60:

Theory of Operation2.5.7. Box Style

- Page 61 and 62:

Theory of OperationFigure 2-27. Poi

- Page 63 and 64:

Theory of Operation2.5.8.3. Shunt C

- Page 65 and 66:

Theory of OperationWARNINGADHERE TO

- Page 67 and 68:

Theory of Operation46POINT DETECTOR

- Page 69 and 70:

Theory of Operation2.5.9.1. Switch

- Page 71 and 72:

Theory of Operation2.5.9.3. Example

- Page 73 and 74:

Installation3. SECTION - INSTALLATI

- Page 75 and 76:

Installation3.3.1. Left- or Right-H

- Page 77 and 78:

InstallationMIN. FOR 5E, 5F ONLYFig

- Page 79 and 80:

Installation3.3.5. Hand-Throw Lever

- Page 81 and 82:

Installation3.3.8. Connect and Init

- Page 83 and 84:

Installation3.3.9. Connect and Init

- Page 85 and 86:

Installation3.4.1. Point Detector R

- Page 87 and 88:

Installation3.4.2. Point Detector R

- Page 89 and 90:

Installation3.4.3. Point Detector R

- Page 91 and 92:

Installation3.5. BEFORE REPLACING M

- Page 93 and 94:

Installation3.5.3. Temperature Cons

- Page 95 and 96:

Installation3.6.2.1. Changing Over

- Page 97 and 98:

InstallationTable 3-12. Changing Ov

- Page 99 and 100:

Installation3.6.2.2. Changing Over

- Page 101 and 102:

InstallationTable 3-13. Changing Ov

- Page 103 and 104:

Installation3.6.3. Changing Over th

- Page 105 and 106:

InstallationTable 3-14. Changing Ov

- Page 107 and 108:

InstallationFigure 3-5. 5H Switch M

- Page 109 and 110:

InstallationTable 3-15. Throw Rod P

- Page 111 and 112:

InstallationTHIS PAGE INTENTIONALLY

- Page 113 and 114:

Scheduled Maintenance4.4. SPECIAL T

- Page 115 and 116:

Scheduled Maintenance4.6. PREVENTIV

- Page 117 and 118:

Scheduled MaintenanceTable 4-2. Sit

- Page 119 and 120:

Scheduled MaintenanceTable 4-3. Lub

- Page 121 and 122:

Scheduled MaintenanceOIL PER ALSTOM

- Page 123 and 124:

Scheduled MaintenanceOIL PER ALSTOM

- Page 125 and 126:

Scheduled Maintenance4.9. QUARTERLY

- Page 127 and 128:

Scheduled MaintenanceTable 4-8. Obs

- Page 129 and 130:

Scheduled Maintenance4.9.3. Motor B

- Page 131 and 132:

Scheduled Maintenance4.9.4. Box-Sty

- Page 133 and 134:

Scheduled MaintenanceTable 4-11. Bo

- Page 135 and 136:

Scheduled MaintenanceTable 4-12. Th

- Page 137 and 138:

Scheduled MaintenanceTable 4-13. Lo

- Page 139 and 140:

Scheduled MaintenanceTable 4-14. Po

- Page 141 and 142:

Scheduled MaintenanceTable 4-15. Po

- Page 143 and 144: Scheduled Maintenance4.9.9. Shunt C

- Page 145 and 146: Scheduled Maintenance4.9.9.2. Model

- Page 147 and 148: Scheduled MaintenanceTable 4-18. Mo

- Page 149 and 150: Scheduled MaintenanceTable 4-19. Co

- Page 151 and 152: Scheduled Maintenance4.9.12. Fricti

- Page 153 and 154: Scheduled Maintenance4.9.13. Fricti

- Page 155 and 156: Scheduled Maintenance4.9.14. Fricti

- Page 157 and 158: Scheduled Maintenance4.9.15. Crank

- Page 159 and 160: Scheduled Maintenance4.10. SEMI-ANN

- Page 161 and 162: Scheduled MaintenanceTable 4-26. Ma

- Page 163 and 164: Scheduled MaintenanceTHIS PAGE INTE

- Page 165 and 166: TroubleshootingTable 5-1. Symptoms

- Page 167 and 168: TroubleshootingTable 5-2. Trackside

- Page 169 and 170: Corrective Maintenance6.2. TEST EQU

- Page 171 and 172: Corrective MaintenanceTable 6-2. Sw

- Page 173 and 174: Corrective MaintenanceTable 6-3. Sw

- Page 175 and 176: Corrective MaintenanceTable 6-6. Cl

- Page 177 and 178: Corrective Maintenance6.4.1. Switch

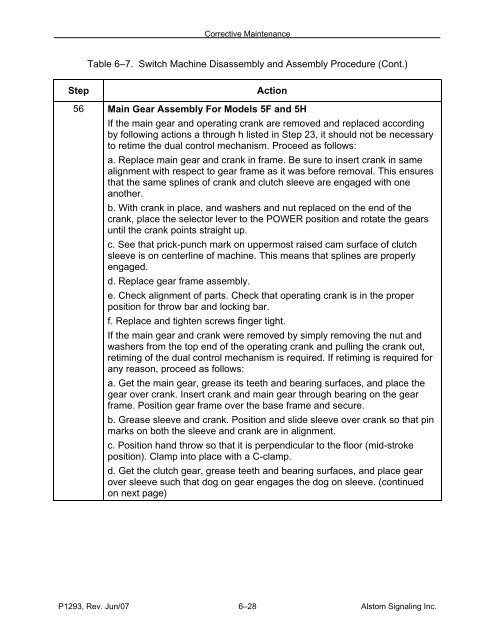

- Page 179 and 180: Corrective MaintenanceTable 6-7. Sw

- Page 181 and 182: Corrective MaintenanceTable 6-7. Sw

- Page 183 and 184: Corrective MaintenanceTable 6-7. Sw

- Page 185 and 186: Corrective MaintenanceTable 6-7. Sw

- Page 187 and 188: Corrective MaintenanceTable 6-7. Sw

- Page 189 and 190: Corrective MaintenanceTable 6-7. Sw

- Page 191 and 192: Corrective MaintenanceTable 6-7. Sw

- Page 193: Corrective MaintenanceTable 6-7. Sw

- Page 197 and 198: Corrective MaintenanceTable 6-7. Sw

- Page 199 and 200: Corrective MaintenanceTable 6-7. Sw

- Page 201 and 202: Corrective MaintenanceTable 6-7. Sw

- Page 203 and 204: Corrective Maintenance6.4.2. MotorT

- Page 205 and 206: Corrective MaintenanceTable 6-8. Mo

- Page 207 and 208: Corrective MaintenanceTable 6-8. Mo

- Page 209 and 210: Corrective MaintenanceTable 6-8. Mo

- Page 211 and 212: Corrective MaintenanceTable 6-8. Mo

- Page 213 and 214: Corrective MaintenanceTable 6-8. Mo

- Page 215 and 216: Corrective MaintenanceTable 6-8. Mo

- Page 217 and 218: Corrective MaintenanceTable 6-8. Mo

- Page 219 and 220: Corrective Maintenance6.4.3. Clutch

- Page 221 and 222: Corrective Maintenance6.4.4. Point

- Page 223 and 224: Corrective MaintenanceTable 6-10. P

- Page 225 and 226: Corrective MaintenanceTable 6-12. C

- Page 227 and 228: Corrective Maintenance6.5.2. Brush

- Page 229 and 230: Corrective Maintenance6.5.4. Motor

- Page 231 and 232: Corrective Maintenance6.5.6. Motor

- Page 233 and 234: Corrective Maintenance6.5.8. Throw

- Page 235 and 236: Corrective Maintenance6.5.12. Lock

- Page 237 and 238: Corrective Maintenance6.5.14. Cutou

- Page 239 and 240: Corrective Maintenance6.5.17. Inter

- Page 241 and 242: Corrective Maintenance6.5.19. Recti

- Page 243 and 244: Corrective Maintenance6.5.22. Conta

- Page 245 and 246:

Corrective Maintenance6.5.24. Arm (

- Page 247 and 248:

Corrective Maintenance6.5.27. Throw

- Page 249 and 250:

Corrective Maintenance6.5.31. Cam B

- Page 251 and 252:

Corrective Maintenance6.6. SWITCH M

- Page 253 and 254:

Corrective MaintenanceTable 6-47. M

- Page 255 and 256:

Corrective MaintenanceTable 6-47. M

- Page 257 and 258:

Corrective MaintenanceTable 6-47. M

- Page 259 and 260:

Corrective MaintenanceTable 6-47. M

- Page 261 and 262:

Corrective MaintenanceTable 6-47. M

- Page 263 and 264:

Corrective MaintenanceTable 6-47. M

- Page 265 and 266:

Corrective MaintenanceTHIS PAGE INT

- Page 267 and 268:

Parts CatalogFigure 7-1. Model 5E S

- Page 269 and 270:

Parts CatalogTable 7-1. Main Parts

- Page 271 and 272:

Parts CatalogFigure 7-3. Model 5F S

- Page 273 and 274:

Parts CatalogTable 7-2. Main Parts

- Page 275 and 276:

Parts CatalogFigure 7-5. Detail Par

- Page 277 and 278:

Parts CatalogTable 7-3. Detail Part

- Page 279 and 280:

Parts CatalogTable 7-3. Detail Part

- Page 281 and 282:

Parts CatalogFigure 7-6. Bars, Coup

- Page 283 and 284:

Parts CatalogFigure 7-7. Brackets,

- Page 285 and 286:

Parts CatalogTable 7-5. Brackets, P

- Page 287 and 288:

Parts CatalogTable 7-6. Selector-Le

- Page 289 and 290:

Parts CatalogTable 7-6. Selector-Le

- Page 291 and 292:

Parts CatalogFigure 7-9. FramesP129

- Page 293 and 294:

Parts CatalogTable 7-7. Frames (Con

- Page 295 and 296:

Parts CatalogTable 7-7. Frames (Con

- Page 297 and 298:

Parts CatalogFigure 7-10. Point-Det

- Page 299 and 300:

Parts CatalogTable 7-8. Point-Detec

- Page 301 and 302:

Parts CatalogFigure 7-11. Lock Rods

- Page 303 and 304:

Parts Catalog67381245ALink MotionFi

- Page 305 and 306:

Parts CatalogFigure 7-13. Biased-Ne

- Page 307 and 308:

Parts CatalogTable 7-11. Biased-Neu

- Page 309 and 310:

Parts CatalogFigure 7-14. Contactor

- Page 311 and 312:

Parts CatalogTable 7-12. Contactor

- Page 313 and 314:

Parts CatalogTable 7-12. Contactor

- Page 315 and 316:

Parts CatalogTable 7-13. Switch Mac

- Page 317 and 318:

Parts CatalogTable 7-13. Switch Mac

- Page 319 and 320:

Parts CatalogTable 7-14. Terminal B

- Page 321 and 322:

Parts CatalogTable 7-15. Wire Entra

- Page 323 and 324:

Parts CatalogTable 7-16. ToolsRefNo

- Page 325 and 326:

DrawingsNWRLRWZR6POINT DETECTOR(NOT

- Page 327 and 328:

DrawingsPOINT DETECTORD8 7 6 5 4 3

- Page 329 and 330:

DrawingsPOINT DETECTORD8 7 6 5 4 3

- Page 331 and 332:

DrawingsTERMINAL BOARDR.H. POINTNOR

- Page 333 and 334:

DrawingsTERMINAL BOARD1 2 3 4 5 6 7

- Page 335:

DrawingsTHIS PAGE INTENTIONALLY LEF