Adept Cobra s600/s800 Robot User's Guide - pulsar.com.tr

Adept Cobra s600/s800 Robot User's Guide - pulsar.com.tr

Adept Cobra s600/s800 Robot User's Guide - pulsar.com.tr

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Mounting the <s<strong>tr</strong>ong>Robot</s<strong>tr</strong>ong><br />

2. While the robot is still bolted to the <strong>tr</strong>ansportation pallet, connect the hydraulic<br />

lift to the eyebolt at the top of the inner link (see Figure 3-1 on page 33). Take up<br />

any slack, but do not lift the robot at this time.<br />

WARNING: Do not attempt to lift the robot at any points<br />

other than the eyebolt provided. Do not attempt to extend<br />

the inner or outer links of the robot until the robot has<br />

been secured in position. Failure to <s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>ply could result in<br />

the robot falling and causing either personnel injury or<br />

equipment damage.<br />

3. Remove the four bolts securing the robot base to the pallet. Retain these bolts for<br />

possible later relocation of the equipment.<br />

4. Lift the robot and position it directly over the mounting surface.<br />

5. Slowly lower the robot while aligning the base and the tapped mounting holes in<br />

the mounting surface.<br />

NOTE: The base casting of the robot is aluminum and can easily be<br />

dented if bumped against a harder surface. Verify that the robot is<br />

mounted squarely (will not rock back and forth) before tightening the<br />

mounting bolts.<br />

6. Install the customer-supplied mounting bolts and washers. Tighten bolts to<br />

torque specified in Table 3-2.<br />

WARNING: The center of mass of the robot may cause the<br />

robot to fall over if the robot is not secured with the<br />

mounting bolts.<br />

NOTE: Check the tightness of the mounting bolts one week after initial<br />

installation, and then recheck every 6 months. See Chapter 7 for periodic<br />

maintenance.<br />

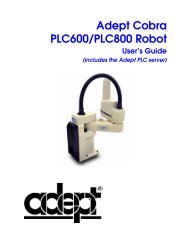

Table 3-2. Mounting Bolt Torque Specifications<br />

Standard Size Specification Torque<br />

Me<strong>tr</strong>ic M12 x P1.75 ISO Property Class 8.8 85 N•m<br />

SAE 7/16-14 UNC SAE Grade 5 65 ft-lb<br />

<s<strong>tr</strong>ong>Adept</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Cobra</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>s600</s<strong>tr</strong>ong>/<s<strong>tr</strong>ong>s800</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Robot</s<strong>tr</strong>ong> User’s <s<strong>tr</strong>ong>Guide</s<strong>tr</strong>ong>, Rev C 37