Adept Cobra s600/s800 Robot User's Guide - pulsar.com.tr

Adept Cobra s600/s800 Robot User's Guide - pulsar.com.tr

Adept Cobra s600/s800 Robot User's Guide - pulsar.com.tr

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

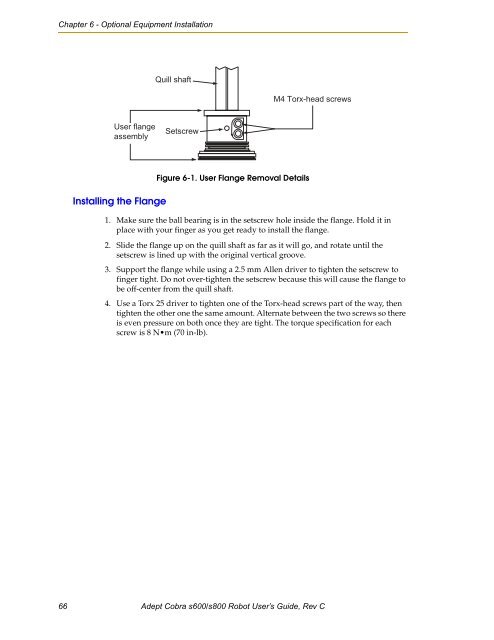

Chapter 6 - Optional Equipment Installation<br />

Quill shaft<br />

M4 Torx-head screws<br />

User flange<br />

assembly<br />

Setscrew<br />

Installing the Flange<br />

Figure 6-1. User Flange Removal Details<br />

1. Make sure the ball bearing is in the setscrew hole inside the flange. Hold it in<br />

place with your finger as you get ready to install the flange.<br />

2. Slide the flange up on the quill shaft as far as it will go, and rotate until the<br />

setscrew is lined up with the original vertical groove.<br />

3. Support the flange while using a 2.5 mm Allen driver to tighten the setscrew to<br />

finger tight. Do not over-tighten the setscrew because this will cause the flange to<br />

be off-center from the quill shaft.<br />

4. Use a Torx 25 driver to tighten one of the Torx-head screws part of the way, then<br />

tighten the other one the same amount. Alternate between the two screws so there<br />

is even pressure on both once they are tight. The torque specification for each<br />

screw is 8 N•m (70 in-lb).<br />

66 <s<strong>tr</strong>ong>Adept</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Cobra</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>s600</s<strong>tr</strong>ong>/<s<strong>tr</strong>ong>s800</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Robot</s<strong>tr</strong>ong> User’s <s<strong>tr</strong>ong>Guide</s<strong>tr</strong>ong>, Rev C