1997 Swinburne Higher Education Handbook

1997 Swinburne Higher Education Handbook

1997 Swinburne Higher Education Handbook

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

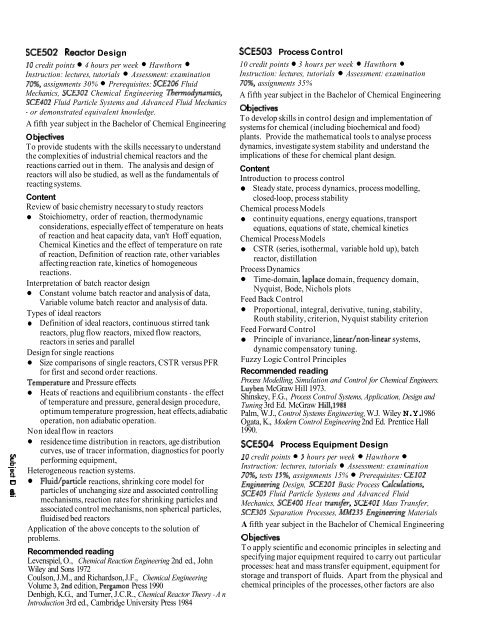

SCE502 Reactor Design<br />

10 credit points 4 hours per week Hawthorn<br />

Instruction: lectures, tutorials Assessment: examination<br />

70%, assignments 30% Prerequisites: SCE206 Fluid<br />

Mechanics, SCE302 Chemical Engineering ~modynamics,<br />

SCE402 Fluid Particle Systems and Advanced Fluid Mechanics<br />

- or demonstrated equivalent knowledge.<br />

A fifth year subject in the Bachelor of Chemical Engineering<br />

Ob jedives<br />

To provide students with the skills necessary to understand<br />

the complexities of industrial chemical reactors and the<br />

reactions carried out in them. The analysis and design of<br />

reactors will also be studied, as well as the fundamentals of<br />

reacting systems.<br />

Content<br />

Review of basic chemistry necessary to study reactors<br />

Stoichiometry, order of reaction, thermodynamic<br />

considerations, especially effect of temperature on heats<br />

of reaction and heat capacity data, van't Hoff equation,<br />

Chemical Kinetics and the effect of temperature on rate<br />

of reaction, Definition of reaction rate, other variables<br />

affecting reaction rate, kinetics of homogeneous<br />

reactions.<br />

Interpretation of batch reactor design<br />

Constant volume batch reactor and analysis of data,<br />

Variable volume batch reactor and analysis of data.<br />

Types of ideal reactors<br />

Definition of ideal reactors, continuous stirred tank<br />

reactors, plug flow reactors, mixed flow reactors,<br />

reactors in series and parallel<br />

Design for single reactions<br />

Size comparisons of single reactors, CSTR versus PFR<br />

for first and second order reactions.<br />

Tem~erature and Pressure effects<br />

Heats of reactions and equilibrium constants - the effect<br />

of temperature and pressure, general design procedure,<br />

optimum temperature progression, heat effects, adiabatic<br />

operation, non adiabatic operation.<br />

Non ideal flow in reactors<br />

residence time distribution in reactors, age distribution<br />

curves, use of tracer information, diagnostics for poorly<br />

rn<br />

performing equipment,<br />

-.<br />

Heterogeneous reaction systems.<br />

0 Fluid/particle reactions, shrinking core model for<br />

3<br />

particles of unchanging size and associated controlling<br />

8.<br />

mechanisms, reaction rates for shrinking particles and<br />

associated control mechanisms, non spherical particles,<br />

fluidised bed reactors<br />

Application of the above concepts to the solution of<br />

problems.<br />

Recommended reading<br />

Levenspiel, O., Chemical Reaction Engineering 2nd ed., John<br />

Wiley and Sons 1972<br />

Coulson, J.M., and Richardson, J.F., Chemical Engineering<br />

Volume 3,2nd edition, Pergamon Press 1990<br />

Denbigh, K.G., and Turner, J.C.R., Chemical Reactor Theory -An<br />

Introduction 3rd ed., Cambridge University Press 1984<br />

SCE503 Process Control<br />

10 credit points 3 hours per week Hawthorn<br />

Instruction: lectures, tutorials Assessment: examination<br />

70%, assignments 35%<br />

A fifth year subject in the Bachelor of Chemical Engineering<br />

0 bjedives<br />

To develop skills in control design and implementation of<br />

systems for chemical (including biochemical and food)<br />

plants. Provide the mathematical tools to analyse process<br />

dynamics, investigate system stability and understand the<br />

implications of these for chemical plant design.<br />

Content<br />

Introduction to process control<br />

Steady state, process dynamics, process modelling,<br />

closed-loop, process stability<br />

Chemical process Models<br />

continuity equations, energy equations, transport<br />

equations, equations of state, chemical kinetics<br />

Chemical Process Models<br />

CSTR (series, isothermal, variable hold up), batch<br />

reactor, distillation<br />

Process Dynamics<br />

Time-domain, laplace domain, frequency domain,<br />

Nyquist, Bode, Nichols plots<br />

Feed Back Control<br />

Proportional, integral, derivative, tuning, stability,<br />

Routh stability, criterion, Nyquist stability criterion<br />

Feed Forward Control<br />

Principle of invariance, linear/non-linear systems,<br />

dynamic compensatory tuning.<br />

Fuzzy Logic Control Principles<br />

Recommended reading<br />

Process Modelling, Simulation and Control for Chemical Engineers.<br />

Luyben McGraw Hill 1973.<br />

Shinskey, F.G., Process Control Systems, Application, Design and<br />

Tuning 3rd Ed. McGraw Hi11,1988<br />

Palm, W.J., Control Systems Engineering, W.J. Wiley N.Y. 1986<br />

Ogata, K., Modern Control Engineering 2nd Ed. Prentice Hall<br />

1990.<br />

SCE504 Process Equipment Design<br />

10 credit points fi hours per week Hawthorn<br />

Instruction: lectures, tutorials Assessment: examination<br />

70%, tests 15%, assignments 15% Prerequisites: CE102<br />

Enginewing Design, SCE201 Basic Process Cakculations,<br />

SCE40fi Fluid Particle Systems and Advanced Fluid<br />

Mechanics, SCE400 Heat transfw, SCE401 Mass Transfer,<br />

SCE305 Separation Processes, MM235 Enginewing Materials<br />

A fifth year subject in the Bachelor of Chemical Engineering<br />

0 bjedives<br />

To apply scientific and economic principles in selecting and<br />

specifying major equipment required to carry out particular<br />

processes: heat and mass transfer equipment, equipment for<br />

storage and transport of fluids. Apart from the physical and<br />

chemical principles of the processes, other factors are also