Effects of dietary n-3 polyunsaturated fatty acids and ... - FINS

Effects of dietary n-3 polyunsaturated fatty acids and ... - FINS

Effects of dietary n-3 polyunsaturated fatty acids and ... - FINS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

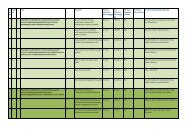

1 st WorkshopXIII International Feed Technology Symposiumapplied technological procedures <strong>and</strong> stability <strong>of</strong> the product in the storage conditions.Animal feeds can serve as a carrier for a wide range <strong>of</strong> microbial contaminants such asbacteria, yeasts, molds <strong>and</strong> their toxic metabolites (mycotoxins) [11]. Such contaminantshave been shown to influence animal performance adversely <strong>and</strong> to compromise thesafety <strong>of</strong> animal products.The growth <strong>and</strong> sporulation <strong>of</strong> microorganisms as well as toxin production to a largeextend are depending from moisture content <strong>of</strong> the substrates (feed ingredients <strong>and</strong>complete feed mixtures) as well as moisture <strong>and</strong> the relative humidity in the storageenvironment. It is known that minimum water activity (a w ) is: for bacterial growth a w =0.90, for yeast growth a w = 0.85 <strong>and</strong> for fungal growth a w = 0.65 [8].One <strong>of</strong> the contemporary feed manufacturing processes for reducing presence <strong>of</strong> themicroorganisms in feed is thermal processing (pelleting) [5]. This process involvesmixing steam with the feed, pressing the mixture through a die, <strong>and</strong> cooling the pelletsafterwards in order to remove heat <strong>and</strong> moisture. If the pelleting process is donecorrectly added 3-5% moisture in the form <strong>of</strong> steam is removed from the feed beforeshipment. However, if this excess moisture is not removed after cooling the pellets, moldgrowth will be encourage since pelleted feeds with higher water content are warmer <strong>and</strong>their storing in a cool bin will cause water condensation on the inside <strong>of</strong> the bin.Although pelleting <strong>of</strong> fodder has been shown to reduce mold <strong>and</strong> bacteria count by thefactor <strong>of</strong> 100 to 100,000 many fungal spores remain in the feed after it was pelleted. Inright conditions the remaining spores can grow <strong>and</strong> produce mycotoxins. Thus, pelletingprocess delays, but does not prevent, the onset <strong>of</strong> fungal growth.So, thermal processing alone will not guarantee the elimination <strong>of</strong> microorganisms. Onthe other h<strong>and</strong>, contaminated incoming ingredients, inadequate housekeeping measures,insects, rodents <strong>and</strong> food traffic through the feed mill can lead to recontamination <strong>of</strong> thefodder.The goal <strong>of</strong> this investigation was to determine influence <strong>of</strong> pelleting procedure <strong>of</strong> calvesmixture on microbiological <strong>and</strong> mycotoxicological proprieties <strong>of</strong> mixture during 150days storage period.MATERIAL AND METHODSSamples. Investigated powdered mixture (11.29% moisture) was produced in FeedMixture Industry, Padinska Skela. Components were mixed with horizontal mixer(Buhler), <strong>of</strong> 3000 t capacity. Pelleting <strong>of</strong> the same mixture was done by the press <strong>of</strong> thesame manufacturer at 75 o C. Pellet diamether was 4 mm, lenght 4 to 6 mm, <strong>and</strong> moisture11.13%. Composition <strong>of</strong> the mixture is shown in Table 1.Immediately after the production <strong>of</strong> feed <strong>and</strong> pelleting, the samples for microbiological<strong>and</strong> mycotoxicological analysis were taken (day 0). Feed mixtures were kept in nylonbags during 150 days <strong>and</strong> sampled periodically (November 2008 – March 2009), at 20cm above the floor, in ventilated, semi-dark <strong>and</strong> dry room. Average room temperaturewas 18 0 C (7-22 0 C).Microbiological investigations were performed according to Regulations on maximalquantity <strong>of</strong> harmful materials <strong>and</strong> ingredients in fodder [17]. Total count <strong>of</strong> bacteria,molds <strong>and</strong> yeasts as well as identification <strong>of</strong> pathogenic microorganisms (E. coli, coagul.positive Staphylococcus spp., Proteus spp., Salmonella spp., sulphito-reducing111