Effects of dietary n-3 polyunsaturated fatty acids and ... - FINS

Effects of dietary n-3 polyunsaturated fatty acids and ... - FINS

Effects of dietary n-3 polyunsaturated fatty acids and ... - FINS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

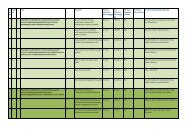

1 st WorkshopXIII International Feed Technology Symposiumwithout time limits in addition to achievement <strong>of</strong> constant operational parameters –pressure <strong>and</strong> temperature. The potential for full utilization is connected to degradation <strong>of</strong>sferozome walls where oil is stored. Destruction <strong>of</strong> the sferozome structure is achievedthrough rapid, but controlled expansion from reactor vessel to exp<strong>and</strong>ed vessel. Rapidmechanical change <strong>of</strong> state in soybeans which is created by quick opening <strong>of</strong> the vesselunder pressure, results in the destruction <strong>of</strong> soybean structure at the end <strong>of</strong> the process.Given the fact that the process is performed with mild thermal preparation <strong>and</strong> themoistening up until mechanical destruction does not occur, the soybean remains wholeor divided into two halves. The soybean that has been thermally treated must be finalizedinto an end product due to the moisture content in treated soybean after thermalprocessing, which ranges between 16-18%. In order to ensure the stability <strong>of</strong> the endproduct, the content <strong>of</strong> surface moisture must be decreased by drying. Direct drying <strong>of</strong>soybeans after completion <strong>of</strong> the cycle by implementing well-known systems, such asfluid or rotational dryer, does not provide optimal results. Namely, high, end temperature<strong>of</strong> soybean which is approximately 80 o C, causes the temperature <strong>of</strong> the drying agent torise, in which case the mass would be exposed to additional thermal shocks <strong>and</strong>inconsistencies, similarly to toasting. The retention time <strong>of</strong> the mass during drying wouldbe short in the above-mentioned systems, that is, it would require a long rotating drum.This would be too expensive <strong>and</strong> would create unfavourable conditions with regard tosudden cooling <strong>and</strong> drying. In order to avoid these types <strong>of</strong> problems, a principle <strong>of</strong>thermal processing <strong>of</strong> the mass is implemented during which the vertical vibrationalmovement along the helicoidically shaped channel occurs. Described technological linefor hydro-thermal treatment <strong>of</strong> is able to process up to 3 t/h <strong>of</strong> soya. The process is basedon batches <strong>and</strong> is intermittent which gave rise to the concept <strong>of</strong> “block” – devices forhydro-thermal treatment where processing is performed semi-continuously. In practice,the implementation <strong>of</strong> this system is equal in simplicity to all widely used systems.Chemical methods for determining soya qualityBasic chemical composition (moisture content, raw proteins, raw fat, raw cellulose <strong>and</strong>minerals) <strong>of</strong> soybean, extruded full fat soya <strong>and</strong> hydro-thermally treated soyabeans isdetermined according to methods A.O.A.C. [4]. The content <strong>of</strong> trypsin inhibitors insoyabean, full-fat soyabean <strong>and</strong> hydro-thermally treated soya bean is determinedaccording to the methods <strong>of</strong> Hamerst<strong>and</strong> <strong>and</strong> associates [10]. Activity <strong>of</strong> urease inanalysed samples is established according to the method prescribed by Internationalst<strong>and</strong>ard ISO 5506 [13].Nitrogen Solubility Index (NSI) is determined according to the A.O.C.S. method [1].Microbiological analysesTotal number <strong>of</strong> micro-organisms, yeasts, molds, isolation <strong>and</strong> identification <strong>of</strong>Salmonella <strong>and</strong> sulfido-reducing clostridia was established according to Regulationsregarding methods <strong>of</strong> applying microbiological analyses <strong>and</strong> superanalyses <strong>of</strong> food [19].Internal laboratory method was used to determine the presence <strong>of</strong> coagulases in positivestaphylococci, Proteus types <strong>and</strong> Escherichia coli. Fifty grams <strong>of</strong> analysed sample isblended with 450 ml <strong>of</strong> prepared sterilized nutritional broth in Erlenmeyer flask.Prepared sample is mildly homogenized <strong>and</strong> incubated for 24 hours at 37 0 C. Isolation238