- Page 1 and 2:

AIR CONDITIONER (MULTI TYPE) SERVIC

- Page 3 and 4:

4-1. Normal Operation (COOL Mode /

- Page 5 and 6:

9-4. Cooling-Season Outdoor Unit Ba

- Page 7 and 8:

Definition of Protective Gear When

- Page 9 and 10:

Precautions for Safety The manufact

- Page 11 and 12:

Use specified parts. When any of th

- Page 13 and 14:

Only a qualified installer (*1) or

- Page 15 and 16:

Specifications Model MMY-MAP0804HT8

- Page 17 and 18:

Carrying in the Outdoor Unit CAUTIO

- Page 19 and 20:

Selection of Pipe Size Coupling siz

- Page 21 and 22:

Table 2 Standard type High Efficien

- Page 23 and 24:

4. Tools (1) Required Tools for R41

- Page 25 and 26:

Models: MMY-MAP1404* and MAP1604 *

- Page 27 and 28:

1-2-2. Compact 4-way Cassette Type

- Page 29 and 30:

1-2-4. 1-way Air Discharge Cassette

- Page 31 and 32:

1-2-6. 2-way Air Discharge Cassette

- Page 33 and 34:

1-2-8. Concealed Duct High Static P

- Page 35 and 36:

1-2-9. Slim Duct Type Models: MMD-A

- Page 37 and 38:

1-2-11.High Wall Type 2 series Mode

- Page 39 and 40:

1-2-13.Floor Standing Cabinet Type

- Page 41 and 42:

1-2-15.Floor Standing Type Models:

- Page 43 and 44:

Models: MMD-AP0721HFE and MMD-AP096

- Page 45 and 46:

2-2. Outdoor Unit (60Hz model: MMY-

- Page 47 and 48:

2-4. Outdoor Inverter (60Hz model:

- Page 49 and 50:

2-way Air Discharge Cassette Type M

- Page 51 and 52:

Concealed Duct High Static Pressure

- Page 53 and 54:

Floor Standing Type Model MMF-AP 01

- Page 55 and 56:

14, 16HP Model: MMY-MAP1404* , MAP1

- Page 57 and 58:

Outdoor Unit (14, 16HP) Model: MMY-

- Page 59 and 60:

2-8-2. Inverter P.C. board for comp

- Page 61 and 62:

3 Refrigerant Piping Systematic Dra

- Page 63 and 64:

Explanation of Functional Parts Fun

- Page 65 and 66:

4 Combined Refrigerant Piping Syste

- Page 67 and 68:

4-3. Normal Operation (HEAT Mode) H

- Page 69 and 70:

4-5. Emergency Operation (Heating O

- Page 71 and 72:

5 Control Outline Indoor Unit Cont

- Page 73 and 74:

NO. Item Specification outline Rema

- Page 75 and 76:

NO. Item Specification outline Rema

- Page 77 and 78:

Outdoor Unit Item Description of op

- Page 79 and 80:

Item Description of operation, nume

- Page 81 and 82:

Item Description of operation, nume

- Page 83 and 84:

Item Description of operation, nume

- Page 85 and 86:

1 Cooling operation under low outsi

- Page 87 and 88:

Central control remote controller (

- Page 89 and 90:

6-1-2. When Wireless Remote Control

- Page 91 and 92:

Central control remote controller (

- Page 93 and 94:

X Y DC5V Power supply circuit Main

- Page 95 and 96:

6-2. Indoor Printed Circuit Board M

- Page 97 and 98:

MCC-1403 Power supply Power supply

- Page 99 and 100:

6-4. Test Operation of Indoor Unit

- Page 101 and 102:

Function CODE No. (DN Code) Table (

- Page 103 and 104:

Type DN code “10” Value Type Mo

- Page 105 and 106:

▼ Ventilating fan control from re

- Page 107 and 108:

6-7. Applied control for Outdoor Un

- Page 109 and 110:

(2) Indoor unit setup method for pr

- Page 111 and 112:

6-8-1. Power peak-cut Control (Stan

- Page 113 and 114:

6-8-3. Snowfall Fan Control Header

- Page 115 and 116:

6-8-6. Operation Mode Selection Con

- Page 117 and 118:

6-8-8. Compressor Operation Output

- Page 119 and 120:

7 TEST OPERATION 7-1. Procedure and

- Page 121 and 122:

(2) In the case that a central cont

- Page 123 and 124:

• Check the additional amount of

- Page 125 and 126:

7-4. Address Setup This product req

- Page 127 and 128:

(Example) Controlling 2 or more ref

- Page 129 and 130:

10 Set the central control address.

- Page 131 and 132:

Manual address setup from the remot

- Page 133 and 134:

To find an indoor unit’s position

- Page 135 and 136:

4 Push the TIME / buttons repeatedl

- Page 137 and 138:

2) Turn on dip switch 2 of SW30 on

- Page 139 and 140:

7-4-4. Check after Address Setup wh

- Page 141 and 142:

7-5-2. Operation from the indoor re

- Page 143 and 144:

Miswiring example Figure Remote con

- Page 145 and 146:

7-6-2. Cooling/Heating Test Operati

- Page 147 and 148:

(2) Test operation START Test opera

- Page 149 and 150:

7-7. Service Support Function 7-7-1

- Page 151 and 152:

7-7-2. Function to Start/Stop (ON/O

- Page 153 and 154:

(2) Heating test operation function

- Page 155 and 156:

(4) Individual start/stop (ON/OFF)

- Page 157 and 158:

(2)Clearing error by using switches

- Page 159 and 160:

7-7-5. Pulse Motor Valve (PMV) Forc

- Page 161 and 162:

7-7-8. Fan Operation Check in Outdo

- Page 163 and 164:

7-7-10.Manual Adjustment Function o

- Page 165 and 166:

7-7-11.Monitor Function of Remote C

- Page 167 and 168:

8 TROUBLESHOOTING 8-1. Overview (1)

- Page 169 and 170:

(Error detected by main remote cont

- Page 171 and 172:

F12 - F12 ALT F15 - F15 ALT F16 - F

- Page 173 and 174:

(Errors detected by IPDU featuring

- Page 175 and 176:

Using TCC-LINK central control remo

- Page 177 and 178:

Light block Check code Cause of fau

- Page 179 and 180:

8-4. Check Codes Displayed on Remot

- Page 181 and 182:

Main remote controller Check code O

- Page 183 and 184:

Main remote controller Check code O

- Page 185 and 186:

Main remote controller Check code O

- Page 187 and 188:

Main remote controller Check code O

- Page 189 and 190:

Main remote controller P04 P05 P07

- Page 191 and 192:

Main remote controller Check code O

- Page 193 and 194:

Errors Detected by TCC-LINK Central

- Page 195 and 196:

8-5. Diagnosis procedure for each c

- Page 197 and 198: Check code Check code name Cause Ch

- Page 199 and 200: Check code Check code name Cause [E

- Page 201 and 202: Check code Check code name Cause [E

- Page 203 and 204: Check code Check code name Cause [F

- Page 205 and 206: Check code Check code name Cause [H

- Page 207 and 208: Check code Check code name Cause [H

- Page 209 and 210: (*3) Check for solenoid valve of al

- Page 211 and 212: Check code Check code name Cause [H

- Page 213 and 214: Check code Check code name Cause [H

- Page 215 and 216: Check code Check code name Cause [L

- Page 217 and 218: Check code Check code name Cause [P

- Page 219 and 220: Check code Check code name Cause [P

- Page 221 and 222: Check code Check code name Cause [P

- Page 223 and 224: (C) Heating operation Does heating

- Page 225 and 226: Check code Check code name Cause [P

- Page 227 and 228: (1)Display of System Information (D

- Page 229 and 230: (3)Display of Outdoor Cycle Data (D

- Page 231 and 232: (5)Display of Indoor Unit Informati

- Page 233 and 234: 8-8. Leakage/Clogging of Refrigerat

- Page 235 and 236: List of Check Codes Generated upon

- Page 237 and 238: 8-9. Sensor Characteristics Outdoor

- Page 239 and 240: Indoor TC1 sensor 200 150 Resistanc

- Page 241 and 242: 240 Outdoor Unit ▼ Ps sensor char

- Page 243 and 244: 9-2. Compressor Backup Operation Se

- Page 245 and 246: (6) Turn on the power supply to all

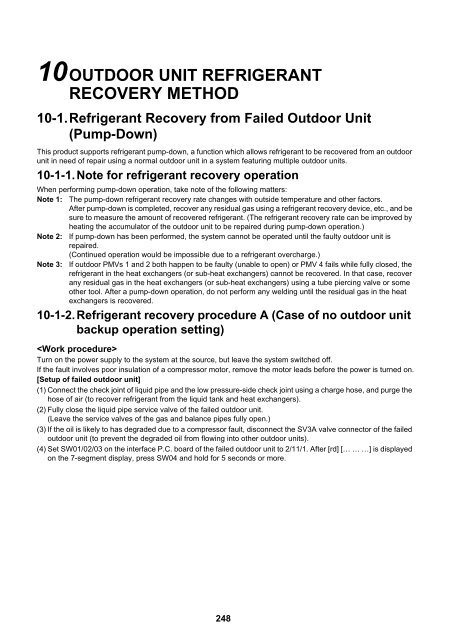

- Page 247: (8) Set Bits 1 and 2 of SW30 on the

- Page 251 and 252: [Setup of failed outdoor unit] (13)

- Page 253 and 254: [Setup of outdoor units other than

- Page 255 and 256: 10-3.Work procedure after Repair Wh

- Page 257 and 258: 11-2.Replacement of Compressors

- Page 259 and 260: [When replacing normal as well as f

- Page 261 and 262: 11-3.Check Procedure to Search Caus

- Page 263 and 264: Check items and procedures to follo

- Page 265 and 266: No. Part to be replaced Work proced

- Page 267 and 268: No. Part to be replaced Work proced

- Page 269 and 270: No. Part to be replaced Work proced

- Page 271 and 272: No. Part to be replaced Work proced

- Page 273 and 274: No. Part to be replaced Work proced

- Page 275 and 276: No. Part to be replaced Work proced

- Page 277 and 278: 13P.C. BOARD EXCHANGE PROCEDURES I

- Page 279 and 280: Procedure 1: Reading Setting Data f

- Page 281 and 282: Procedure 3: Writing Setting Data i

- Page 283 and 284: CODE No. list (Example) CODE No. (D

- Page 285 and 286: 13-2-3.Interface board (MCC-1606) r

- Page 287 and 288: (6) Set the dip switch (SW800) sett

- Page 289 and 290: 13-2-6.Noise Filter P.C. Board (MCC

- Page 291 and 292: (7) Install the service P.C. boards

- Page 293 and 294: 292

- Page 295 and 296: SMMS-i OUTDOOR UNIT MMY-MAP1404HT8(

- Page 297 and 298: REFRIGERATION CIRCUIT DIAGRAM M MOT

- Page 299 and 300:

Ref. No. Part No. Description MAP08

- Page 301 and 302:

SMMS-i INV SERVICE PARTS LIST MMY-M

- Page 303 and 304:

SMMS-i OUTDOOR UNIT MMY-MAP0804T8(Z

- Page 305 and 306:

REFRIGERATION CIRCUIT DIAGRAM M MOT

- Page 307 and 308:

306

- Page 309 and 310:

Ref. No. Part No. Description MAP08

- Page 311 and 312:

SMMS-i INV SERVICE PARTS LIST MMY-M

- Page 313 and 314:

Ref. No. Part No. Description MAP08

- Page 315 and 316:

314

- Page 317 and 318:

SMMS-i OUTDOOR UNIT MMY-MAP1404HT8(

- Page 319 and 320:

REFRIGERATION CIRCUIT DIAGRAM M MOT

- Page 321 and 322:

Ref. No. Part No. Description MAP08

- Page 323 and 324:

SMMS-i INV SERVICE PARTS LIST MMY-M

- Page 325 and 326:

SMMS-i OUTDOOR UNIT MMY-MAP0804T8(Z

- Page 327 and 328:

REFRIGERATION CIRCUIT DIAGRAM M MOT

- Page 329 and 330:

328

- Page 331 and 332:

Ref. No. Part No. Description MAP08

- Page 333 and 334:

SMMS-i INV SERVICE PARTS LIST MMY-M

- Page 335 and 336:

Ref. No. Part No. Description MAP08

- Page 337 and 338:

336

- Page 339 and 340:

SMMS-i OUTDOOR UNIT MMY-MAP1404HT8(

- Page 341 and 342:

REFRIGERATION CIRCUIT DIAGRAM M MOT

- Page 343 and 344:

Ref. No. Part No. Description MAP08

- Page 345 and 346:

SMMS-i INV SERVICE PARTS LIST MMY-M

- Page 347 and 348:

SMMS-i OUTDOOR UNIT MMY-MAP0804HT7(

- Page 349 and 350:

REFRIGERATION CIRCUIT DIAGRAM M MOT

- Page 351 and 352:

350

- Page 353 and 354:

Ref. No. Part No. Description MAP08

- Page 355 and 356:

SMMS-i INV SERVICE PARTS LIST MMY-M

- Page 357 and 358:

Ref. No. Part No. Description MAP08

- Page 359 and 360:

358

- Page 361 and 362:

SMMS-i OUTDOOR UNIT MMY-MAP1404T8-S

- Page 363 and 364:

REFRIGERATION CIRCUIT DIAGRAM M MOT

- Page 365 and 366:

Ref. No. Part No. Description MAP08

- Page 367 and 368:

SMMS-i INV SERVICE PARTS LIST MMY-M

- Page 369 and 370:

WARNINGS ON REFRIGERANT LEAKAGE Che