- Page 2 and 3:

COLLECTION OF PAPERS PRESENTED AT T

- Page 4 and 5:

III

- Page 6 and 7:

V

- Page 8 and 9:

Table of Contents Wednesday 11 May

- Page 10 and 11:

PANEL DISCUSSION TEXTILE MICROSYSTE

- Page 12 and 13:

Friday 13 May SESSION C4: APPLICATI

- Page 14 and 15:

SPECIAL SESSION OF BIO-MEMS/NEMS a

- Page 16 and 17:

11-13 May 2011, Aix-en-Provence, Fr

- Page 18 and 19:

11-13 May 2011, Aix-en-Provence, F

- Page 20 and 21:

11-13 May 2011, Aix-en-Provence, F

- Page 22 and 23:

11-13 May 2011, Aix-en-Provence, F

- Page 24 and 25:

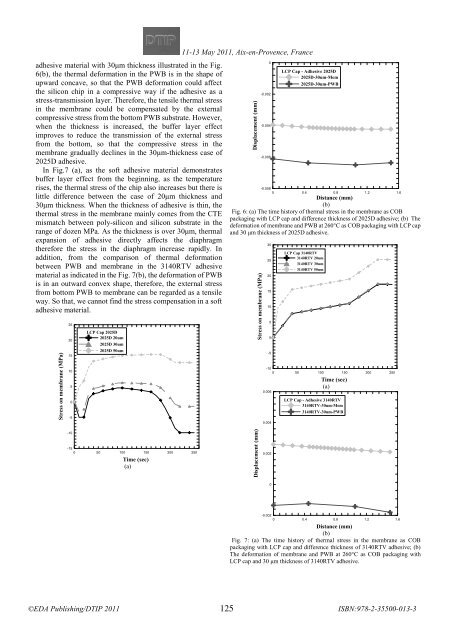

suspended membrane can be pulled to

- Page 26 and 27:

most likely due to not yet consider

- Page 28 and 29:

11-13 May 2011, Aix-en-Provence, F

- Page 30 and 31:

that detectors may measure the diff

- Page 32 and 33:

2) Cavity width effect To verify th

- Page 34 and 35:

11-13 May 2011, Aix-en-Provence, Fr

- Page 36 and 37:

Fig.9. Capacitive sensor output, Va

- Page 38 and 39:

11-13 May, 2011, Aix-en-Provence,

- Page 40 and 41:

The anode and cathode are connected

- Page 42 and 43:

11-13 May , 2011 , Aix-en-Provence,

- Page 44 and 45:

11-13 May 2011, Aix-en-Provence, F

- Page 46 and 47:

11-13 May 2011, Aix-en-Provence, Fr

- Page 48 and 49:

11-13 May 2011, Aix-en-Provence, F

- Page 50 and 51:

! 11-13 May 2011, Aix-en-Provence,

- Page 52 and 53:

! 11-13 May 2011, Aix-en-Provence,

- Page 54 and 55:

! TABLE 3 SUMMARY OF SELECTIVITIES

- Page 56 and 57:

11-13 May 2011, Aix-en-Provence, Fr

- Page 58 and 59:

11-13 May 2011, Aix-en-Provence, Fr

- Page 60 and 61:

11-13 May 2011, Aix-en-Provence, Fr

- Page 62 and 63:

The fabrication of optical Cap-Wafe

- Page 64 and 65:

the glass is polished down in a cos

- Page 66 and 67:

11-13 May 2011, Aix-en-Provence, Fr

- Page 68 and 69:

11-13 May 2011, Aix-en-Provence, F

- Page 70 and 71:

11-13 May 2011, Aix-en-Provence, F

- Page 72 and 73:

Fig. 14. Time history of the envelo

- Page 74 and 75:

11-13 May 2011, Aix-en-Provence, F

- Page 76 and 77:

11-13 May 2011, Aix-en-Provence, Fr

- Page 78 and 79:

We have reported that how base mode

- Page 80 and 81:

We assume that 11-13 May 2011, Aix

- Page 82 and 83:

11-13 May 2011, Aix-en-Provence, F

- Page 84 and 85:

Y X Fig. 1. Scanning electron mic

- Page 86 and 87:

10 3 11-13 May 2011, Aix-en-Proven

- Page 88 and 89:

Intenstiy (counts/second) Fig. 1. X

- Page 90 and 91: 11-13 May 2011, Aix-en-Provence, Fr

- Page 92 and 93: 11-13 May 2011, Aix-en-Provence, Fr

- Page 94 and 95: etween x 2 to L (remember that x 2

- Page 96 and 97: 11-13 May 2011, Aix-en-Provence, F

- Page 98 and 99: 11-13 May 2011, Aix-en-Provence, F

- Page 100 and 101: 11-13 May 2011, Aix-en-Provence, Fr

- Page 102 and 103: 11-13 May 2011, Aix-en-Provence, Fr

- Page 104 and 105: 11-13 May 2011, Aix-en-Provence, F

- Page 106 and 107: piezoelectric displacement transduc

- Page 108 and 109: Figure 7 Displacement conditions of

- Page 110 and 111: protect the corners from undercut.

- Page 112 and 113: 11-13 May 2011, Aix-en-Provence, F

- Page 114 and 115: A. Continuous domain Starting from

- Page 116 and 117: Fig. 8. Central finite difference m

- Page 118 and 119: 11-13 May 2011, Aix-en-Provence, F

- Page 120 and 121: 700 11-13 May 2011, Aix-en-Provenc

- Page 122 and 123: o o o o o o o o Check applicability

- Page 124 and 125: C. Identification Results The ident

- Page 126 and 127: The proposed solution for this prob

- Page 128 and 129: teen wire segments of a coil, as in

- Page 130 and 131: As the metallization is too reflect

- Page 132 and 133: B. Implemented die overview A die c

- Page 134 and 135: 11-13 May 2011, Aix-en-Provence, F

- Page 136 and 137: IN CLK OUT Fig. 16. Probe setup for

- Page 138 and 139: 11-13 May 2011, Aix-en-Provence, F

- Page 142 and 143: 11-13 May 2011, Aix-en-Provence, F

- Page 144 and 145: 11-13 May 2011, Aix-en-Provence, F

- Page 146 and 147: B. Dynamics of Energy Flows For a l

- Page 148 and 149: 11-13 May 2011, Aix-en-Provence, F

- Page 150 and 151: 11-13 May 2011, Aix-en-Provence, F

- Page 152 and 153: 11-13 May, Aix-en-Provence, France

- Page 154 and 155: 80˚C. Additionally, we looked into

- Page 156 and 157: The XRD shows a peak above the 2θ

- Page 158 and 159: fibers which define the electric co

- Page 160 and 161: 11-13 May 2011, Aix-en-Provence, Fr

- Page 162 and 163: Figure 15. Key board input system.

- Page 164 and 165: ρ = h 2∆α∆T + + E 1h 3 1 +E 2

- Page 166 and 167: 11-13 May 2011, Aix-en-Provence, Fr

- Page 168 and 169: In recent years, the pipe flow moni

- Page 170 and 171: As the speed of the rotor increases

- Page 172 and 173: 11-13 May 2011, Aix-en-Provence, F

- Page 174 and 175: 11-13 May 2011, Aix-en-Provence, Fr

- Page 176 and 177: inches silicon wafers which have th

- Page 178 and 179: samples tested in different vacuum

- Page 180 and 181: l c 11-13 May 2011, Aix-en-Provence

- Page 182 and 183: Vp (V) 3,5 3,0 2,5 2,0 1,5 1,0 0,5

- Page 184 and 185: 11-13 May 2011, Aix-en-Provence, Fr

- Page 186 and 187: II. MATHEMATICAL MODEL AND NUMERICA

- Page 188 and 189: fluids travel along a curved channe

- Page 190 and 191:

measured mixing indices are depicte

- Page 192 and 193:

length, which enables them to focus

- Page 194 and 195:

11-13 May 2011, Aix-en-Provence, F

- Page 196 and 197:

however, a rotation for coincidence

- Page 198 and 199:

11-13 May 2011, Aix-en-Provence, F

- Page 200 and 201:

11-13 May 2011, Aix-en-Provence, F

- Page 202 and 203:

11-13 May 2011, Aix-en-Provence, F

- Page 204 and 205:

excludes the nature of the fixed bo

- Page 206 and 207:

Using the radial and tangential mid

- Page 208 and 209:

11-13 May 2011, Aix-en-Provence, F

- Page 210 and 211:

11-13 May 2011, Aix-en-Provence, F

- Page 212 and 213:

11-13 May 2011, Aix-en-Provence, F

- Page 214 and 215:

11-13 May 2011, Aix-en-Provence, F

- Page 216 and 217:

Now the challenge in data handling

- Page 218 and 219:

value of every active channel. Ther

- Page 220 and 221:

11-13 May 2011, Aix-en-Provence, F

- Page 222 and 223:

11-13 May, Aix-en-Provence, France

- Page 224 and 225:

11-13 May, Aix-en-Provence, France

- Page 226 and 227:

11-13 May 2011, Aix-en-Provence, Fr

- Page 228 and 229:

11-13 May 2011, Aix-en-Provence, Fr

- Page 230 and 231:

electrocardiogram. • The heart be

- Page 232 and 233:

11-13 May 2011, Aix-en-Provence, F

- Page 234 and 235:

In our work, we proposed an innovat

- Page 236 and 237:

Fig. 8 Concept of the in-home perso

- Page 238 and 239:

found that the early-stage diagnosi

- Page 240 and 241:

11-13 May 2011, Aix-en-Provence, F

- Page 242 and 243:

11-13 May 2011, Aix-en-Provence, F

- Page 244 and 245:

Power monitoring data detected by w

- Page 246 and 247:

11-13 May 2011, Aix-en-Provence, F

- Page 248 and 249:

device consisted of a bimorph canti

- Page 250 and 251:

where C others is the capacitance o

- Page 252 and 253:

11-13 May 2011, Aix-en-Provence, F

- Page 254 and 255:

11-13 May 2011, Aix-en-Provence, F

- Page 256 and 257:

11-13 May 2011, Aix-en-Provence, F

- Page 258 and 259:

operation, the pressure inside the

- Page 260 and 261:

11-13 May 2011, Aix-en-Provence, F

- Page 262 and 263:

increased. 11-13 May 2011, Aix-en-

- Page 264 and 265:

11-13 May 2011, Aix-en-Provence, F

- Page 266 and 267:

coefficient compatible with the mic

- Page 268 and 269:

11-13 May 2011, Aix-en-Provence, F

- Page 270 and 271:

Variable Description Value Crab-leg

- Page 272 and 273:

11-13 May 2011, Aix-en-Provence, F

- Page 274 and 275:

11-13 May 2011, Aix-en-Provence, F

- Page 276 and 277:

Membrane weight (mg) Fig. 4. Struct

- Page 278 and 279:

11-13 May 2011, Aix-en-Provence, F

- Page 280 and 281:

11-13 May 2011, Aix-en-Provence, F

- Page 282 and 283:

So far, the expected major contribu

- Page 284 and 285:

al. used a modified LIGA (German ac

- Page 286 and 287:

11-13 May 2011, Aix-en-Provence, F

- Page 288 and 289:

11-13 May 2011, Aix-en-Provence, F

- Page 290 and 291:

11-13 May 2011, Aix-en-Provence, F

- Page 292 and 293:

REFERENCES [1] G. Mehta, J. Lee, W.

- Page 294 and 295:

11-13 May 2011, Aix-en-Provence, F

- Page 296 and 297:

followed by titanium (Ti) which sho

- Page 298 and 299:

exposure dose, post exposure bake t

- Page 300 and 301:

#### ##/&### 3 # #

- Page 302 and 303:

*5%6,+/.,-,7-, ,+.,1/21* %

- Page 304 and 305:

B. Energy Applications Society is f

- Page 306 and 307:

11-13 May 2011, Aix-en-Provence, Fr

- Page 308 and 309:

11-13 May 2011, Aix-en-Provence, Fr

- Page 310 and 311:

11-13 May 2011, Aix-en-Provence, F

- Page 312 and 313:

11-13 May 2011, Aix-en-Provence, F

- Page 314 and 315:

Presently, the microfabrication pro

- Page 316 and 317:

[6] C. Richard, A. Renaudin, V. Aim

- Page 318 and 319:

NA sinθ c 11-13 May 2011, Aix-en-

- Page 320 and 321:

the waveguide on the fused silica,

- Page 322 and 323:

microphone diaphragm. The chosen CM

- Page 324 and 325:

11-13 May 2011, Aix-en-Provence, F

- Page 326 and 327:

TABLE V MICROPHONE CHARACTERISTICS

- Page 328 and 329:

11-13 May 2011, Aix-en-Provence, F

- Page 330 and 331:

Figure 7b shows the effect of a par

- Page 332 and 333:

11-13 May 2011, Aix-en-Provence, F

- Page 334 and 335:

over the temperature range (i.e. th

- Page 336 and 337:

11-13 May 2011, Aix-en-Provence, F

- Page 338 and 339:

11-13 May 2011, Aix-en-Provence, F

- Page 340 and 341:

given. This allows a CTM model to b

- Page 342 and 343:

11-13 May 2011, Aix-en-Provence, F

- Page 344 and 345:

11-13 May 2011, Aix-en-Provence, F

- Page 346 and 347:

11-13 May 2011, Aix-en-Provence, F

- Page 348 and 349:

the magic-Tee, and the coherent sig

- Page 350 and 351:

11-13 May 2011, Aix-en-Provence, F

- Page 352 and 353:

After analyzing the two conditions

- Page 354 and 355:

IV. MICRO FABRICATION For fabricati

- Page 356 and 357:

11-13 May 2011, Aix-en-Provence, F

- Page 358 and 359:

IV. A. Simulation and Sensitivity A

- Page 360 and 361:

11-13 May 2011, Aix-en-Provence, Fr

- Page 362 and 363:

11-13 May 2011, Aix-en-Provence, Fr

- Page 364 and 365:

11-13 May 2011, Aix-en-Provence, Fr

- Page 366 and 367:

grown to sub-confluence were washed

- Page 368 and 369:

11-13 May 2011, Aix-en-Provence, F

- Page 370 and 371:

Clamps rotation [21] Clamps transla

- Page 372 and 373:

Layout Total dimensions of the grip

- Page 374 and 375:

11-13 May 2011, Aix-en-Provence, F

- Page 376 and 377:

focusing increased both as the stre

- Page 378 and 379:

11-13 May, 2011, Aix-en-Provence,

- Page 380 and 381:

Time of diffusion (hr) 1200 1000 80

- Page 382 and 383:

11-13 May, 2011, Aix-en-Provence,

- Page 384 and 385:

11-13 May 2011, Aix-en-Provence, F

- Page 386 and 387:

Chip Magnet Light source Hot plate

- Page 388 and 389:

above, they would move to upward an

- Page 390 and 391:

11-13 May 2011, Aix-en-Provence, F

- Page 392 and 393:

11-13 May 2011, Aix-en-Provence, F

- Page 394 and 395:

11-13 May, 2011, Aix-en-Provence,

- Page 396 and 397:

11-13 May, 2011, Aix-en-Provence,

- Page 398 and 399:

11-13 May, 2011, Aix-en-Provence,

- Page 400 and 401:

This phenomenon is now reaching the

- Page 402 and 403:

C. Proof mass displacement Moreover

- Page 404 and 405:

11-13 May 2011, Aix-en-Provence, Fr

- Page 406 and 407:

11-13 May 2011, Aix-en-Provence, Fr

- Page 408 and 409:

The VerilogA block code is : 11-13

- Page 410 and 411:

Author Index Abi-Saab D. 81 Aimez V

- Page 412:

Nussbaum Dominic 273 O’Hara T. 35