Online proceedings - EDA Publishing Association

Online proceedings - EDA Publishing Association

Online proceedings - EDA Publishing Association

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

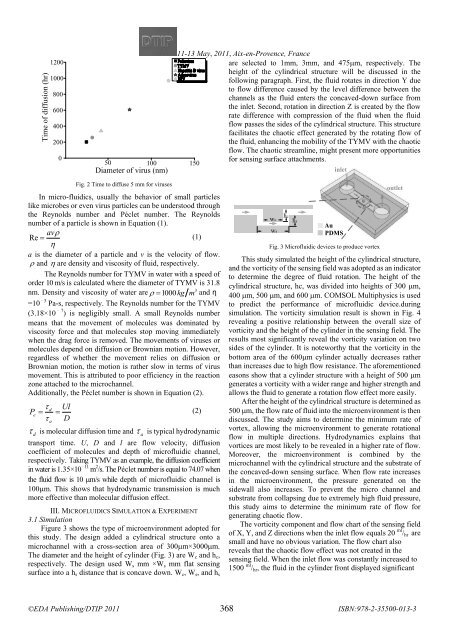

Time of diffusion (hr)<br />

1200<br />

1000<br />

800<br />

600<br />

400<br />

200<br />

0<br />

11-13 <br />

May, 2011, Aix-en-Provence, France<br />

<br />

Poliovirus<br />

TYMV<br />

Hepatitis B virus<br />

Adenovirus<br />

HIV<br />

50 100 150<br />

Diameter of virus (nm)<br />

are selected to 1mm, 3mm, and 475m, respectively. The<br />

height of the cylindrical structure will be discussed in the<br />

following paragraph. First, the fluid rotates in direction Y due<br />

to flow difference caused by the level difference between the<br />

channels as the fluid enters the concaved-down surface from<br />

the inlet. Second, rotation in direction Z is created by the flow<br />

rate difference with compression of the fluid when the fluid<br />

flow passes the sides of the cylindrical structure. This structure<br />

facilitates the chaotic effect generated by the rotating flow of<br />

the fluid, enhancing the mobility of the TYMV with the chaotic<br />

flow. The chaotic streamline, might present more opportunities<br />

for sensing surface attachments.<br />

inlet<br />

Fig. 2 Time to diffuse 5 mm for viruses<br />

In micro-fluidics, usually the behavior of small particles<br />

like microbes or even virus particles can be understood through<br />

the Reynolds number and Péclet number. The Reynolds<br />

number of a particle is shown in Equation (1).<br />

av<br />

Re (1)<br />

<br />

a is the diameter of a particle and v is the velocity of flow.<br />

and are density and viscosity of fluid, respectively.<br />

The Reynolds number for TYMV in water with a speed of<br />

order 10 m/s is calculated where the diameter of TYMV is 31.8<br />

3<br />

nm. Density and viscosity of water are 1000kg m and η<br />

=10 –3 Pa-s, respectively. The Reynolds number for the TYMV<br />

(3.18×10 – 7 ) is negligibly small. A small Reynolds number<br />

means that the movement of molecules was dominated by<br />

viscosity force and that molecules stop moving immediately<br />

when the drag force is removed. The movements of viruses or<br />

molecules depend on diffusion or Brownian motion. However,<br />

regardless of whether the movement relies on diffusion or<br />

Brownian motion, the motion is rather slow in terms of virus<br />

movement. This is attributed to poor efficiency in the reaction<br />

zone attached to the microchannel.<br />

Additionally, the Péclet number is shown in Equation (2).<br />

<br />

Ul<br />

d<br />

Pe<br />

(2)<br />

<br />

a<br />

D<br />

<br />

d<br />

is molecular diffusion time and<br />

a<br />

is typical hydrodynamic<br />

transport time. U, D and l are flow velocity, diffusion<br />

coefficient of molecules and depth of microfluidic channel,<br />

respectively. Taking TYMV as an example, the diffusion coefficient<br />

in water is 1.35×10 –11 m 2 /s. The Péclet number is equal to 74.07 when<br />

the fluid flow is 10 m/s while depth of microfluidic channel is<br />

100m. This shows that hydrodynamic transmission is much<br />

more effective than molecular diffusion effect.<br />

III. MICROFLUIDICS SIMULATION & EXPERIMENT<br />

3.1 Simulation<br />

Figure 3 shows the type of microenvironment adopted for<br />

this study. The design added a cylindrical structure onto a<br />

microchannel with a cross-section area of 300m×3000m.<br />

The diameter and the height of cylinder (Fig. 3) are W c and h c ,<br />

respectively. The design used W s mm ×W s mm flat sensing<br />

surface into a h s distance that is concave down. W c , W s , and h s<br />

wc<br />

ws<br />

hc<br />

hs<br />

Au<br />

PDMS<br />

Fig. 3 Microfluidic devices to produce vortex<br />

outlet<br />

This study simulated the height of the cylindrical structure,<br />

and the vorticity of the sensing field was adopted as an indicator<br />

to determine the degree of fluid rotation. The height of the<br />

cylindrical structure, hc, was divided into heights of 300 m,<br />

400 m, 500 m, and 600 m. COMSOL Multiphysics is used<br />

to predict the performance of microfluidic device.during<br />

simulation. The vorticity simulation result is shown in Fig. 4<br />

revealing a positive relationship between the overall size of<br />

vorticity and the height of the cylinder in the sensing field. The<br />

results most significantly reveal the vorticity variation on two<br />

sides of the cylinder. It is noteworthy that the vorticity in the<br />

bottom area of the 600m cylinder actually decreases rather<br />

than increases due to high flow resistance. The aforementioned<br />

easons show that a cylinder structure with a height of 500 m<br />

generates a vorticity with a wider range and higher strength and<br />

allows the fluid to generate a rotation flow effect more easily.<br />

After the height of the cylindrical structure is determined as<br />

500 m, the flow rate of fluid into the microenvironment is then<br />

discussed. The study aims to determine the minimum rate of<br />

vortex, allowing the microenvironment to generate rotational<br />

flow in multiple directions. Hydrodynamics explains that<br />

vortices are most likely to be revealed in a higher rate of flow.<br />

Moreover, the microenvironment is combined by the<br />

microchannel with the cylindrical structure and the substrate of<br />

the concaved-down sensing surface. When flow rate increases<br />

in the microenvironment, the pressure generated on the<br />

sidewall also increases. To prevent the micro channel and<br />

substrate from collapsing due to extremely high fluid pressure,<br />

this study aims to determine the minimum rate of flow for<br />

generating chaotic flow.<br />

The vorticity component and flow chart of the sensing field<br />

of X, Y, and Z directions when the inlet flow equals 20 ml / hr are<br />

small and have no obvious variation. The flow chart also<br />

reveals that the chaotic flow effect was not created in the<br />

sensing field. When the inlet flow was constantly increased to<br />

1500 ml / hr , the fluid in the cylinder front displayed significant<br />

368