Online proceedings - EDA Publishing Association

Online proceedings - EDA Publishing Association

Online proceedings - EDA Publishing Association

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

TABLE V<br />

MICROPHONE CHARACTERISTICS<br />

Characteristics Value<br />

Resonant frequency 10 kHz<br />

Open circuit sensitivity -35 dB.V/Pa<br />

SNR<br />

68 dB<br />

Fig. 9. Simulated spectral density of the output noise voltage.<br />

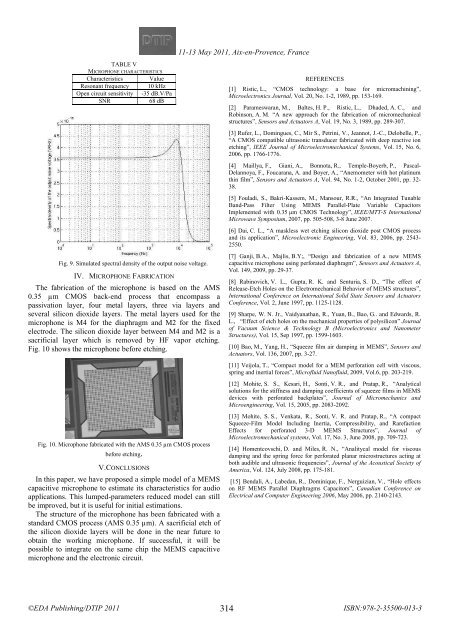

IV. MICROPHONE FABRICATION<br />

The fabrication of the microphone is based on the AMS<br />

0.35 µm CMOS back-end process that encompass a<br />

passivation layer, four metal layers, three via layers and<br />

several silicon dioxide layers. The metal layers used for the<br />

microphone is M4 for the diaphragm and M2 for the fixed<br />

electrode. The silicon dioxide layer between M4 and M2 is a<br />

sacrificial layer which is removed by HF vapor etching.<br />

Fig. 10 shows the microphone before etching.<br />

Fig. 10. Microphone fabricated with the AMS 0.35 µm CMOS process<br />

before etching.<br />

V. CONCLUSIONS<br />

In this paper, we have proposed a simple model of a MEMS<br />

capacitive microphone to estimate its characteristics for audio<br />

applications. This lumped-parameters reduced model can still<br />

be improved, but it is useful for initial estimations.<br />

The structure of the microphone has been fabricated with a<br />

standard CMOS process (AMS 0.35 µm). A sacrificial etch of<br />

the silicon dioxide layers will be done in the near future to<br />

obtain the working microphone. If successful, it will be<br />

possible to integrate on the same chip the MEMS capacitive<br />

microphone and the electronic circuit.<br />

11-13 <br />

May 2011, Aix-en-Provence, France<br />

<br />

REFERENCES<br />

[1] Ristic, L., “CMOS technology: a base for micromachining”,<br />

Microelectronics Journal, Vol. 20, No. 1-2, 1989, pp. 153-169.<br />

[2] Parameswaran, M., Baltes, H. P., Ristic, L., Dhaded, A. C., and<br />

Robinson, A. M. “A new approach for the fabrication of micromechanical<br />

structures”, Sensors and Actuators A, Vol. 19, No. 3, 1989, pp. 289-307.<br />

[3] Rufer, L., Domingues, C., Mir S., Petrini, V., Jeannot, J.-C., Delobelle, P.,<br />

“A CMOS compatible ultrasonic transducer fabricated with deep reactive ion<br />

etching”, IEEE Journal of Microelectromechanical Systems, Vol. 15, No. 6,<br />

2006, pp. 1766-1776.<br />

[4] Maillya, F., Giani, A., Bonnota, R., Temple-Boyerb, P., Pascal-<br />

Delannoya, F., Foucarana, A. and Boyer, A., “Anemometer with hot platinum<br />

thin film”, Sensors and Actuators A, Vol. 94, No. 1-2, October 2001, pp. 32-<br />

38.<br />

[5] Fouladi, S., Bakri-Kassem, M., Mansour, R.R., “An Integrated Tunable<br />

Band-Pass Filter Using MEMS Parallel-Plate Variable Capacitors<br />

Implemented with 0.35 μm CMOS Technology”, IEEE/MTT-S International<br />

Microwave Symposium, 2007, pp. 505-508, 3-8 June 2007.<br />

[6] Dai, C. L., “A maskless wet etching silicon dioxide post CMOS process<br />

and its application”, Microelectronic Engineering, Vol. 83, 2006, pp. 2543-<br />

2550.<br />

[7] Ganji, B.A., Majlis, B.Y;, “Design and fabrication of a new MEMS<br />

capacitive microphone using perforated diaphragm”, Sensors and Actuators A,<br />

Vol. 149, 2009, pp. 29-37.<br />

[8] Rabinovich, V. L., Gupta, R. K. and Senturia, S. D., “The effect of<br />

Release-Etch Holes on the Electromechanical Behavior of MEMS structures”,<br />

International Conference on International Solid State Sensors and Actuators<br />

Conference, Vol. 2, June 1997, pp. 1125-1128.<br />

[9] Sharpe, W. N. Jr., Vaidyanathan, R., Yuan, B., Bao, G.. and Edwards, R.<br />

L., “Effect of etch holes on the mechanical properties of polysilicon” Journal<br />

of Vacuum Science & Technology B (Microelectronics and Nanometer<br />

Structures), Vol. 15, Sep 1997, pp. 1599-1603.<br />

[10] Bao, M., Yang, H., “Squeeze film air damping in MEMS”, Sensors and<br />

Actuators, Vol. 136, 2007, pp. 3-27.<br />

[11] Veijola, T., “Compact model for a MEM perforation cell with viscous,<br />

spring and inertial forces”, Microfluid Nanofluid, 2009, Vol.6, pp. 203-219.<br />

[12] Mohite, S. S., Kesari, H., Sonti, V. R., and Pratap, R., “Analytical<br />

solutions for the stiffness and damping coefficients of squeeze films in MEMS<br />

devices with perforated backplates”, Journal of Micromechanics and<br />

Microengineering, Vol. 15, 2005, pp. 2083-2092.<br />

[13] Mohite, S. S., Venkata, R., Sonti, V. R. and Pratap, R., “A compact<br />

Squeeze-Film Model Including Inertia, Compressibility, and Rarefaction<br />

Effects for perforated 3-D MEMS Structures”, Journal of<br />

Microelectromechanical systems, Vol. 17, No. 3, June 2008, pp. 709-723.<br />

[14] Homentcovschi, D. and Miles, R. N., “Analitycal model for viscous<br />

damping and the spring force for perforated planar microstructures acting at<br />

both audible and ultrasonic frequencies”, Journal of the Acoustical Society of<br />

America, Vol. 124, July 2008, pp. 175-181.<br />

[15] Bendali, A., Labedan, R., Dominique, F., Nerguizian, V., “Hole effects<br />

on RF MEMS Parallel Diaphragms Capacitors”, Canadian Conference on<br />

Electrical and Computer Engineering 2006, May 2006, pp. 2140-2143.<br />

©<strong>EDA</strong> <strong>Publishing</strong>/DTIP 2011<br />

<br />

314<br />

ISBN:978-2-35500-013-3