Controls, Start-Up, Operation, Service and ... - Climayoreo

Controls, Start-Up, Operation, Service and ... - Climayoreo

Controls, Start-Up, Operation, Service and ... - Climayoreo

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

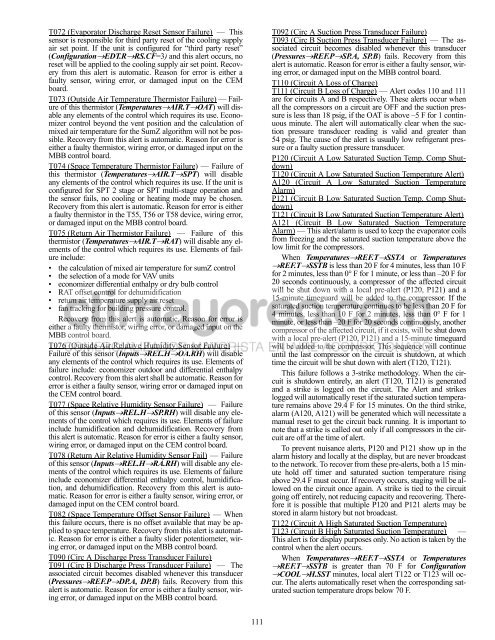

T072 (Evaporator Discharge Reset Sensor Failure) — This<br />

sensor is responsible for third party reset of the cooling supply<br />

air set point. If the unit is configured for “third party reset”<br />

(ConfigurationEDT.RRS.CF=3) <strong>and</strong> this alert occurs, no<br />

reset will be applied to the cooling supply air set point. Recovery<br />

from this alert is automatic. Reason for error is either a<br />

faulty sensor, wiring error, or damaged input on the CEM<br />

board.<br />

T073 (Outside Air Temperature Thermistor Failure) — Failure<br />

of this thermistor (TemperaturesAIR.TOAT) will disable<br />

any elements of the control which requires its use. Economizer<br />

control beyond the vent position <strong>and</strong> the calculation of<br />

mixed air temperature for the SumZ algorithm will not be possible.<br />

Recovery from this alert is automatic. Reason for error is<br />

either a faulty thermistor, wiring error, or damaged input on the<br />

MBB control board.<br />

T074 (Space Temperature Thermistor Failure) — Failure of<br />

this thermistor (TemperaturesAIR.TSPT) will disable<br />

any elements of the control which requires its use. If the unit is<br />

configured for SPT 2 stage or SPT multi-stage operation <strong>and</strong><br />

the sensor fails, no cooling or heating mode may be chosen.<br />

Recovery from this alert is automatic. Reason for error is either<br />

a faulty thermistor in the T55, T56 or T58 device, wiring error,<br />

or damaged input on the MBB control board.<br />

T075 (Return Air Thermistor Failure) — Failure of this<br />

thermistor (TemperaturesAIR.TRAT) will disable any elements<br />

of the control which requires its use. Elements of failure<br />

include:<br />

• the calculation of mixed air temperature for sumZ control<br />

• the selection of a mode for VAV units<br />

• economizer differential enthalpy or dry bulb control<br />

• RAT offset control for dehumidification<br />

• return air temperature supply air reset<br />

• fan tracking for building pressure control.<br />

Recovery from this alert is automatic. Reason for error is<br />

either a faulty thermistor, wiring error, or damaged input on the<br />

MBB control board.<br />

T076 (Outside Air Relative Humidity Sensor Failure) —<br />

Failure of this sensor (InputsREL.HOA.RH) will disable<br />

any elements of the control which requires its use. Elements of<br />

failure include: economizer outdoor <strong>and</strong> differential enthalpy<br />

control. Recovery from this alert shall be automatic. Reason for<br />

error is either a faulty sensor, wiring error or damaged input on<br />

the CEM control board.<br />

T077 (Space Relative Humidity Sensor Failure) — Failure<br />

of this sensor (InputsREL.HSP.RH) will disable any elements<br />

of the control which requires its use. Elements of failure<br />

include humidification <strong>and</strong> dehumidification. Recovery from<br />

this alert is automatic. Reason for error is either a faulty sensor,<br />

wiring error, or damaged input on the CEM control board.<br />

T078 (Return Air Relative Humidity Sensor Fail) — Failure<br />

of this sensor (InputsREL.HRA.RH) will disable any elements<br />

of the control which requires its use. Elements of failure<br />

include economizer differential enthalpy control, humidification,<br />

<strong>and</strong> dehumidification. Recovery from this alert is automatic.<br />

Reason for error is either a faulty sensor, wiring error, or<br />

damaged input on the CEM control board.<br />

T082 (Space Temperature Offset Sensor Failure) — When<br />

this failure occurs, there is no offset available that may be applied<br />

to space temperature. Recovery from this alert is automatic.<br />

Reason for error is either a faulty slider potentiometer, wiring<br />

error, or damaged input on the MBB control board.<br />

T090 (Circ A Discharge Press Transducer Failure)<br />

T091 (Circ B Discharge Press Transducer Failure) — The<br />

associated circuit becomes disabled whenever this transducer<br />

(PressuresREF.PDP.A, DP.B) fails. Recovery from this<br />

alert is automatic. Reason for error is either a faulty sensor, wiring<br />

error, or damaged input on the MBB control board.<br />

111<br />

T092 (Circ A Suction Press Transducer Failure)<br />

T093 (Circ B Suction Press Transducer Failure) — The associated<br />

circuit becomes disabled whenever this transducer<br />

(PressuresREF.PSP.A, SP.B) fails. Recovery from this<br />

alert is automatic. Reason for error is either a faulty sensor, wiring<br />

error, or damaged input on the MBB control board.<br />

T110 (Circuit A Loss of Charge)<br />

T111 (Circuit B Loss of Charge) — Alert codes 110 <strong>and</strong> 111<br />

are for circuits A <strong>and</strong> B respectively. These alerts occur when<br />

all the compressors on a circuit are OFF <strong>and</strong> the suction pressure<br />

is less than 18 psig, if the OAT is above –5 F for 1 continuous<br />

minute. The alert will automatically clear when the suction<br />

pressure transducer reading is valid <strong>and</strong> greater than<br />

54 psig. The cause of the alert is usually low refrigerant pressure<br />

or a faulty suction pressure transducer.<br />

P120 (Circuit A Low Saturated Suction Temp. Comp Shutdown)<br />

T120 (Circuit A Low Saturated Suction Temperature Alert)<br />

A120 (Circuit A Low Saturated Suction Temperature<br />

Alarm)<br />

P121 (Circuit B Low Saturated Suction Temp. Comp Shutdown)<br />

T121 (Circuit B Low Saturated Suction Temperature Alert)<br />

A121 (Circuit B Low Saturated Suction Temperature<br />

Alarm) — This alert/alarm is used to keep the evaporator coils<br />

from freezing <strong>and</strong> the saturated suction temperature above the<br />

low limit for the compressors.<br />

When TemperaturesREF.TSSTA or Temperatures<br />

REF.TSSTB is less than 20 F for 4 minutes, less than 10 F<br />

for 2 minutes, less than 0° F for 1 minute, or less than –20 F for<br />

20 seconds continuously, a compressor of the affected circuit<br />

will be shut down with a local pre-alert (P120, P121) <strong>and</strong> a<br />

15-minute timeguard will be added to the compressor. If the<br />

saturated suction temperature continues to be less than 20 F for<br />

4 minutes, less than 10 F for 2 minutes, less than 0° F for 1<br />

minute, or less than –20 F for 20 seconds continuously, another<br />

compressor of the affected circuit, if it exists, will be shut down<br />

with a local pre-alert (P120, P121) <strong>and</strong> a 15-minute timeguard<br />

will be added to the compressor. This sequence will continue<br />

until the last compressor on the circuit is shutdown, at which<br />

time the circuit will be shut down with alert (T120, T121).<br />

This failure follows a 3-strike methodology. When the circuit<br />

is shutdown entirely, an alert (T120, T121) is generated<br />

<strong>and</strong> a strike is logged on the circuit. The Alert <strong>and</strong> strikes<br />

logged will automatically reset if the saturated suction temperature<br />

remains above 29.4 F for 15 minutes. On the third strike,<br />

alarm (A120, A121) will be generated which will necessitate a<br />

manual reset to get the circuit back running. It is important to<br />

note that a strike is called out only if all compressors in the circuit<br />

are off at the time of alert.<br />

To prevent nuisance alerts, P120 <strong>and</strong> P121 show up in the<br />

alarm history <strong>and</strong> locally at the display, but are never broadcast<br />

to the network. To recover from these pre-alerts, both a 15 minute<br />

hold off timer <strong>and</strong> saturated suction temperature rising<br />

above 29.4 F must occur. If recovery occurs, staging will be allowed<br />

on the circuit once again. A strike is tied to the circuit<br />

going off entirely, not reducing capacity <strong>and</strong> recovering. Therefore<br />

it is possible that multiple P120 <strong>and</strong> P121 alerts may be<br />

stored in alarm history but not broadcast.<br />

T122 (Circuit A High Saturated Suction Temperature)<br />

T123 (Circuit B High Saturated Suction Temperature) —<br />

This alert is for display purposes only. No action is taken by the<br />

control when the alert occurs.<br />

When TemperaturesREF.TSSTA or Temperatures<br />

REF.TSSTB is greater than 70 F for Configuration<br />

COOLH.SST minutes, local alert T122 or T123 will occur.<br />

The alerts automatically reset when the corresponding saturated<br />

suction temperature drops below 70 F.