Controls, Start-Up, Operation, Service and ... - Climayoreo

Controls, Start-Up, Operation, Service and ... - Climayoreo

Controls, Start-Up, Operation, Service and ... - Climayoreo

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

set point (ConfigurationIAQAQ.SP menu) <strong>and</strong> the supply<br />

fan is on, the economizer minimum vent position (ConfigurationIAQDCV.CEC.MN)<br />

is overridden <strong>and</strong> the<br />

damper is moved to the IQ.P.O configuration. When the DAQ<br />

falls below the DAQ.L set point (ConfigurationIAQAQ.SP<br />

menu), the economizer damper is moved<br />

back to the minimum vent position (EC.MN).<br />

NOTE: Configuration OAQ.U is used in the calculation of the<br />

trip point for override <strong>and</strong> can be found under Configuration<br />

IAQAQ.SP.<br />

IQ.A.C = 3 (4 to 20 mA Damper Control) — This configuration<br />

will provide full 4 to 20 mA remotely controlled analog input<br />

for economizer minimum damper position. The 4 to 20 mA<br />

signal is connected to terminals TB201-8 <strong>and</strong> TB201-7. The<br />

input is processed as 4 mA = 0% <strong>and</strong> 20 mA = 100%, thereby<br />

giving complete range control of the effective minimum<br />

position.<br />

The economizer sequences can be disabled by unpluging<br />

the enthalpy switch input <strong>and</strong> not enabling any other economizer<br />

changeover sequence at ConfigurationECONE.SEL.<br />

Complete control of the economizer<br />

damper position is then possible by using a 4 to 20 mA economizer<br />

minimum position control or a 0 to 10 kilo-ohm 0 to<br />

100% economizer minimum position control via configuration<br />

decisions at ConfigurationIAQIQ.A.C.<br />

To disable the st<strong>and</strong>ard enthalpy control input function,<br />

unplug the enthalpy switch <strong>and</strong> provide a jumper from TB201-<br />

6 to TB201-5 (see wiring diagrams in Major System Components<br />

section on page 116).<br />

IQ.A.C = 4 (10 Kohm Potentiometer Damper Control) —<br />

This configuration will provide input for a 10 kilo-ohm linear<br />

potentiometer that acts as a remotely controlled analog input<br />

for economizer minimum damper position. The input is processed<br />

as 0 ohms = 0% <strong>and</strong> 10,000 ohms = 100%, thereby giving<br />

complete range control of the effective minimum position.<br />

NOTE: For complete economizer control, the user can make<br />

the economizer inactive by unplugging the enthalpy switch<br />

connection.<br />

CONTROLS OPERATION<br />

Modes — The ComfortLink controls operate under a<br />

hierarchy of comm<strong>and</strong> structure as defined by three essential<br />

elements: the System mode, the HVAC mode <strong>and</strong> the Control<br />

mode. The System mode is the top level mode that defines three<br />

essential states for the control system: OFF, RUN <strong>and</strong> TEST.<br />

The HVAC mode is the functional level underneath the<br />

System mode which further defines the operation of the<br />

control.<br />

The Control mode is essentially the control type of the unit<br />

(ConfigurationUNITC.TYP). This defines from where<br />

the control looks to establish a cooling or heating mode.<br />

Furthermore, there are a number of modes which operate<br />

concurrently when the unit is running. The operating modes of<br />

the control are located at the local displays under Operating<br />

Modes. See Table 30.<br />

Currently Occupied (OCC) — This variable displays the current<br />

occupancy state of the unit.<br />

Timed Override in Effect (T.OVR) — This variable displays<br />

if the state of occupancy is currently occupied due to an<br />

override.<br />

DCV Resetting Minimum Position (DCV) — This variable<br />

displays if the economizer position has been lowered from its<br />

maximum vent position due to dem<strong>and</strong> control ventilation.<br />

Supply Air Reset (SA.R) — This variable displays if the supply<br />

air set point that the rooftop is attempting to maintain is<br />

currently being reset upwards. This applies to cooling only.<br />

40<br />

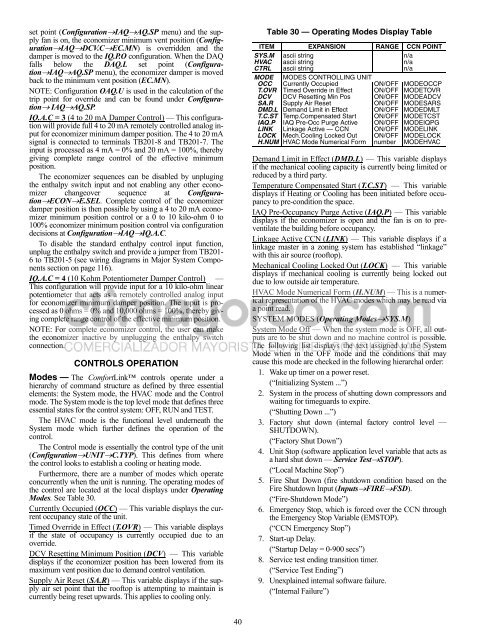

Table 30 — Operating Modes Display Table<br />

ITEM EXPANSION RANGE CCN POINT<br />

SYS.M ascii string n/a<br />

HVAC ascii string n/a<br />

CTRL ascii string n/a<br />

MODE MODES CONTROLLING UNIT<br />

OCC Currently Occupied ON/OFF MODEOCCP<br />

T.OVR Timed Override in Effect ON/OFF MODETOVR<br />

DCV DCV Resetting Min Pos ON/OFF MODEADCV<br />

SA.R Supply Air Reset ON/OFF MODESARS<br />

DMD.L Dem<strong>and</strong> Limit in Effect ON/OFF MODEDMLT<br />

T.C.ST Temp.Compensated <strong>Start</strong> ON/OFF MODETCST<br />

IAQ.P IAQ Pre-Occ Purge Active ON/OFF MODEIQPG<br />

LINK Linkage Active — CCN ON/OFF MODELINK<br />

LOCK Mech.Cooling Locked Out ON/OFF MODELOCK<br />

H.NUM HVAC Mode Numerical Form number MODEHVAC<br />

Dem<strong>and</strong> Limit in Effect (DMD.L) — This variable displays<br />

if the mechanical cooling capacity is currently being limited or<br />

reduced by a third party.<br />

Temperature Compensated <strong>Start</strong> (T.C.ST) — This variable<br />

displays if Heating or Cooling has been initiated before occupancy<br />

to pre-condition the space.<br />

IAQ Pre-Occupancy Purge Active (IAQ.P) — This variable<br />

displays if the economizer is open <strong>and</strong> the fan is on to preventilate<br />

the building before occupancy.<br />

Linkage Active CCN (LINK) — This variable displays if a<br />

linkage master in a zoning system has established “linkage”<br />

with this air source (rooftop).<br />

Mechanical Cooling Locked Out (LOCK) — This variable<br />

displays if mechanical cooling is currently being locked out<br />

due to low outside air temperature.<br />

HVAC Mode Numerical Form (H.NUM) — This is a numerical<br />

representation of the HVAC modes which may be read via<br />

a point read.<br />

SYSTEM MODES (Operating ModesSYS.M)<br />

System Mode Off — When the system mode is OFF, all outputs<br />

are to be shut down <strong>and</strong> no machine control is possible.<br />

The following list displays the text assigned to the System<br />

Mode when in the OFF mode <strong>and</strong> the conditions that may<br />

cause this mode are checked in the following hierarchal order:<br />

1. Wake up timer on a power reset.<br />

(“Initializing System ...”)<br />

2. System in the process of shutting down compressors <strong>and</strong><br />

waiting for timeguards to expire.<br />

(“Shutting Down ...”)<br />

3. Factory shut down (internal factory control level —<br />

SHUTDOWN).<br />

(“Factory Shut Down”)<br />

4. Unit Stop (software application level variable that acts as<br />

a hard shut down — <strong>Service</strong> TestSTOP).<br />

(“Local Machine Stop”)<br />

5. Fire Shut Down (fire shutdown condition based on the<br />

Fire Shutdown Input (InputsFIREFSD).<br />

(“Fire-Shutdown Mode”)<br />

6. Emergency Stop, which is forced over the CCN through<br />

the Emergency Stop Variable (EMSTOP).<br />

(“CCN Emergency Stop”)<br />

7. <strong>Start</strong>-up Delay.<br />

(“<strong>Start</strong>up Delay = 0-900 secs”)<br />

8. <strong>Service</strong> test ending transition timer.<br />

(“<strong>Service</strong> Test Ending”)<br />

9. Unexplained internal software failure.<br />

(“Internal Failure”)